To ensure safety in fuel supply, focus on strict storage, handling, and transfer practices while regularly inspecting equipment for leaks or damage. Maintain detailed records, follow proper procedures, and keep staff trained in emergency response and spill management. Monitoring fuel quality and contamination risks is vital. By following these straightforward steps, you minimize risks and ensure compliance. Keep going to discover more essential safety tips to protect your operations effectively.

Key Takeaways

- Regularly inspect and maintain fuel storage tanks, transfer equipment, and safety devices to prevent leaks and ensure safe operation.

- Implement comprehensive staff training on safety protocols, regulatory compliance, and emergency response procedures.

- Use approved containers, proper grounding, and secure transfer practices to minimize contamination and static buildup risks.

- Keep detailed records of inspections, testing, fuel inventory, and incident reports for accountability and compliance.

- Develop, review, and regularly update safety plans, spill response protocols, and emergency procedures for continuous improvement.

Assessing Fuel Storage and Handling Practices

To guarantee safe fuel supply management, you need to evaluate your storage and handling practices carefully. Start by inspecting your fuel storage tanks for signs of corrosion, leaks, or damage. Ensure tanks are properly labeled and stored in ventilated, secure areas away from ignition sources. Handling practices must include strict procedures for transferring fuel, such as using approved containers and equipment. Train personnel regularly on safe handling procedures, emphasizing the importance of avoiding spills and static buildup. Maintain accurate inventory records to track fuel levels and expiration dates. Proper storage and handling reduce the risk of fires, leaks, and environmental contamination. Additionally, inspecting self-watering plant pots can serve as a reminder of how proper design features contribute to safety and efficiency. Proper storage and handling reduce the risk of fires, leaks, and environmental contamination. Regularly reviewing and improving these practices keeps your fuel supply secure and compliant with safety regulations.

Ensuring Proper Equipment Maintenance and Inspection

Regularly performing proper inspection procedures helps you catch issues early before they cause problems. Scheduling routine maintenance keeps equipment in top condition and reduces the risk of failures. Training your staff guarantees everyone understands how to maintain and inspect equipment effectively, keeping safety at the forefront. Incorporating performance upgrades can further optimize equipment responsiveness and longevity.

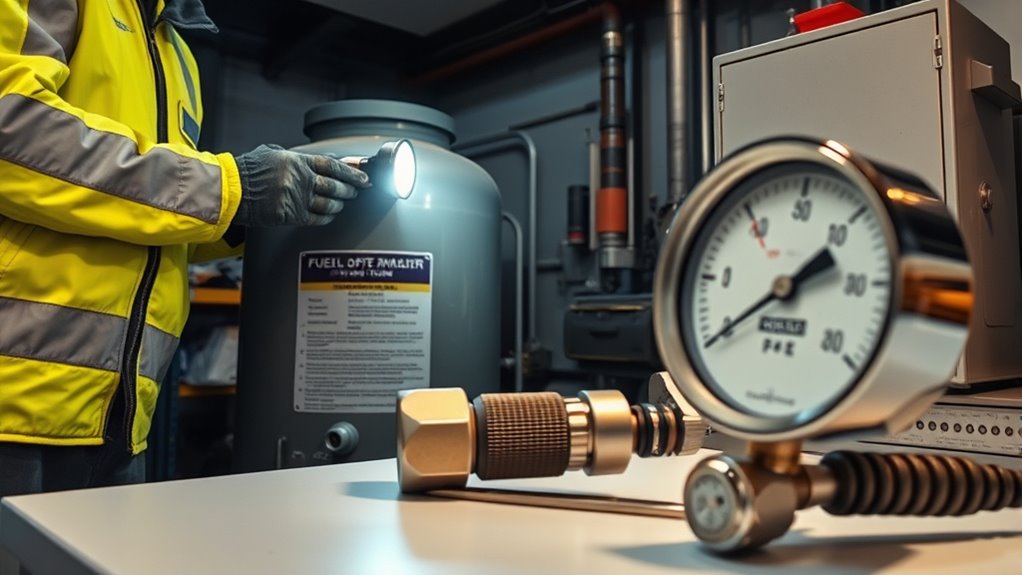

Proper Inspection Procedures

Are you confident that your equipment is always ready for safe fuel operations? Proper inspection procedures are essential to maintaining this confidence. Regular checks help identify issues before they escalate, especially during times of fluctuating fuel pricing and supply chain disruptions. You should verify that all safety valves, gauges, and hoses are intact and functioning correctly. Look for signs of wear, corrosion, or leaks, and ensure that fuel filters are clean and effective. Document inspections thoroughly to track equipment performance over time. By following precise inspection procedures, you reduce risks, prevent costly downtime, and ensure compliance. Staying proactive with inspections keeps your operations safe, efficient, and resilient against the unpredictable challenges posed by market fluctuations and supply chain issues. Incorporating preventive maintenance into your routine further enhances equipment reliability and safety.

Routine Maintenance Scheduling

Effective routine maintenance scheduling is essential for ensuring your equipment remains in ideal condition for safe fuel operations. Regular inspections prevent breakdowns, help you stay compliant with environmental regulations, and adapt to fluctuating fuel pricing. By maintaining a consistent schedule, you reduce risks like leaks or malfunctions that could lead to safety hazards or environmental damage. Use the table below to prioritize tasks:

| Maintenance Task | Frequency |

|---|---|

| Inspect fuel storage tanks | Monthly |

| Check safety valves | Weekly |

| Service pumps and filters | Quarterly |

Sticking to this plan ensures your equipment performs reliably, minimizes costs, and keeps you aligned with environmental standards. Proper scheduling is your best defense against unexpected issues and regulatory penalties. Regularly Kia Tuning upgrades can also enhance the performance and safety of your fuel system components.

Staff Training and Awareness

Since proper equipment maintenance depends heavily on staff awareness, training your team guarantees that inspections and repairs are performed correctly and promptly. Well-trained staff ensure fuel safety by recognizing potential issues early and maintaining equipment properly. To boost staff competence, provide regular training sessions focused on inspection procedures, safety protocols, and troubleshooting techniques. Keep your team updated on new regulations and best practices for fuel handling. Foster a safety-conscious environment where staff feel confident to report concerns and perform inspections diligently. Remember, consistent training minimizes errors, reduces downtime, and enhances overall safety. Well-informed employees are your best defense against equipment failure and safety hazards, ensuring reliable fuel supply and compliance with safety standards. Additionally, understanding supermarket hours and other operational schedules can help in planning maintenance activities to avoid peak times and minimize disruptions.

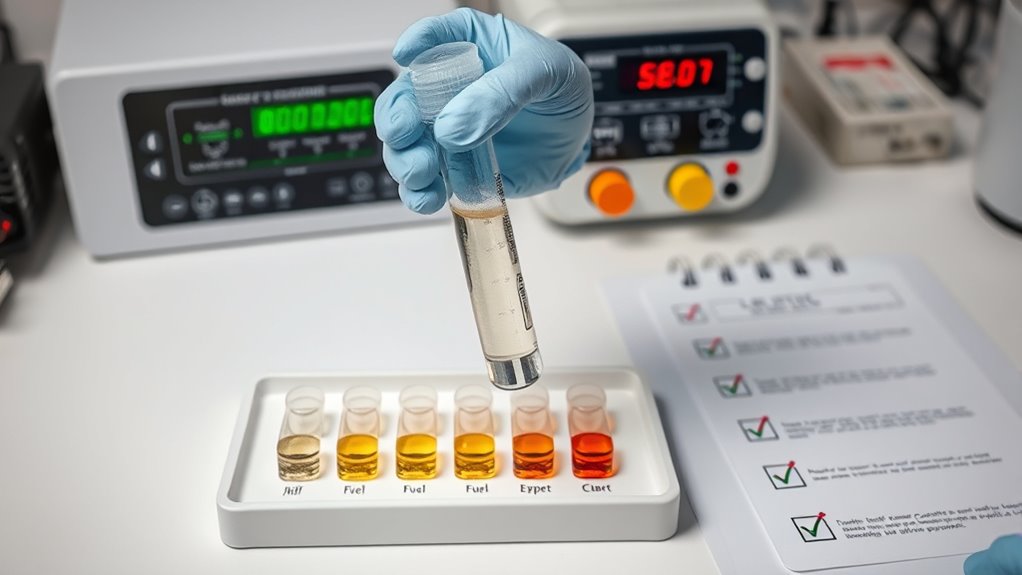

Verifying Fuel Quality and Contamination Prevention

Ensuring fuel quality and preventing contamination are critical steps in maintaining a safe and reliable supply. You need to verify that the fuel meets quality standards through contamination testing, which identifies impurities or water that could harm equipment. Proper contamination testing helps catch issues early, preventing costly damage or failures. Additionally, selecting the right fuel additive can enhance fuel stability and reduce the risk of microbial growth or sediment formation. Always use approved testing methods and keep detailed records of results. Regularly review your testing procedures to guarantee accuracy. Implementing proper storage practices is also essential for maintaining fuel integrity over time. By diligently verifying fuel quality and making informed decisions on fuel additive selection, you minimize contamination risks and ensure your fuel remains safe and effective for use.

Implementing Safe Delivery and Transfer Procedures

When implementing safe delivery and transfer procedures, you need to confirm the delivery credentials to guarantee proper authorization. Using the right transfer equipment helps prevent leaks and spills, keeping everyone safe. Throughout the transfer, you should monitor the process closely to catch any issues early and respond promptly. Incorporating industry trends into your procedures ensures you stay current with best practices and safety standards.

Confirm Delivery Credentials

Before accepting a fuel delivery, you need to verify the credentials of the delivery personnel. This step guarantees safety and compliance with regulations. Start by checking their fuel delivery documentation to confirm they’re authorized for the job. Credential verification includes reviewing IDs, licenses, and company credentials to prevent unauthorized access. Confirm the delivery vehicle’s registration and markings match the documentation. Always ask for proof of training or certification related to fuel handling. Ensuring these details are accurate minimizes risks and maintains safety standards. Remember, a quick but thorough credential check helps prevent potential theft, accidents, or contamination. Incorporating security protocols into your process further enhances safety and accountability. Never skip this step, as verifying credentials is a crucial part of implementing safe delivery and transfer procedures. Protect your site by making credential verification a non-negotiable part of your process.

Use Proper Transfer Equipment

Using the proper transfer equipment is essential for safe and efficient fuel delivery. Always select the right fuel transfer equipment designed for your specific fuel type and delivery setup. Ensure all hoses, couplings, and fittings are in good condition, free of leaks or damage. Adhere to transfer safety protocols by grounding and bonding containers to prevent static buildup. Confirm that valves are closed before connecting and opening them slowly to avoid spills. Never force connections or use makeshift tools. Proper transfer equipment minimizes hazards, prevents spills, and reduces fire risks. Regularly inspect and maintain your equipment to guarantee optimal performance. Additionally, understanding the benefits of raw food can promote safer handling practices by emphasizing the importance of cleanliness and proper storage. Following these practices helps maintain safety standards, protects personnel, and guarantees smooth, secure fuel transfers every time.

Monitor During Transfer

Monitoring the transfer process is essential to guarantee safety and prevent accidents. Staying alert during transfer ensures you can quickly spot issues like leaks, pressure changes, or equipment malfunctions. Follow safety protocols diligently to minimize risks. Keep an eye on gauges and alarms, and never leave the transfer unattended. Effective monitoring involves regular checks and clear communication with your team. Remember, quick action can prevent spills or dangerous situations. Consistently monitor during transfer to maintain control and safety. Security systems can also provide an extra layer of oversight by alerting you immediately to any unusual activity or breaches during the process.

Establishing Emergency Response and Spill Management Plans

To effectively manage fuel supply emergencies, you must establish clear response and spill management plans that outline specific procedures and responsibilities. These plans help ensure quick, coordinated action during incidents, minimizing environmental and safety risks. Include protocols for controlling spills, reporting procedures, and cleanup steps. Make sure your plan accounts for fuel pricing fluctuations, so response measures remain cost-effective under changing economic conditions. Regulatory compliance is critical; your plan must meet all local, state, and federal requirements to avoid penalties and legal issues. Regularly review and update these plans to adapt to new regulations and operational changes. Clear communication channels and designated roles are essential, enabling your team to respond swiftly and effectively when emergencies occur.

Training Staff on Safety Protocols and Emergency Procedures

Training staff on safety protocols and emergency procedures is essential to guarantee everyone knows how to respond effectively during fuel supply incidents. Proper training ensures your team can handle situations swiftly, minimizing risks related to fuel pricing fluctuations and regulatory compliance. Well-trained staff can identify hazards early, follow safety guidelines, and act decisively under pressure. This reduces the chance of accidents and ensures compliance with industry standards. Regular drills reinforce procedures, keeping safety top of mind. By emphasizing clear communication and quick response, you protect your team and assets. Continuous education also helps staff stay updated on changes in safety regulations and fuel management practices. Ultimately, thorough training creates a safer, more compliant operation that’s better prepared for any emergency.

- Conduct regular safety drills and refreshers

- Educate on regulatory compliance requirements

- Clarify roles during emergencies

- Review fuel handling and spill response procedures

Maintaining Accurate Record-Keeping and Compliance Monitoring

Accurate record-keeping and compliance monitoring are essential for ensuring your fuel supply operations meet industry standards and legal requirements. You must prioritize record precision to track fuel deliveries, usage, and inventory levels exactly. This helps identify discrepancies early and prevents issues like shortages or overstocking. Regular compliance monitoring ensures you stay aligned with regulations, safety protocols, and environmental standards. Implement a system for documenting all transactions and inspections consistently. Keep detailed logs and audit trails to support regulatory reviews and internal audits. Staying organized and diligent in maintaining records not only safeguards your operations but also minimizes legal risks. By emphasizing record accuracy and continuous compliance monitoring, you create a safer, more reliable fuel supply process that adheres to all required standards.

Frequently Asked Questions

How Often Should Fuel Storage Tanks Be Inspected for Safety?

You should inspect your fuel storage tanks at least annually to guarantee safety and proper tank maintenance. Regular inspections help identify corrosion, leaks, or other issues early, preventing costly repairs or environmental hazards. In addition to annual inspections, perform visual checks monthly and after any severe weather. Consistent inspection frequency helps maintain tank integrity, ensures compliance with safety regulations, and minimizes fuel supply issues, keeping your operations safe and efficient.

What Are the Signs of Fuel Contamination to Watch Out For?

You should watch for signs of fuel contamination like sediment, water, or cloudy appearance. Fuel additive testing helps identify chemical changes, while contamination detection methods such as water detection kits or visual inspections reveal impurities. If you notice strange smells, inconsistent engine performance, or abnormal fuel color, it’s a sign to examine your fuel right away. Regular testing and monitoring ensure your fuel stays clean and safe for use.

How Can I Ensure Compliance With Local Fuel Safety Regulations?

Think of compliance as steering a river safely. You must follow the current of fuel safety regulations, ensuring your fuel quality meets standards and safety protocols are strictly followed. Regularly review local laws, conduct ongoing staff training, and perform routine inspections. Keep detailed records of all fuel sources and safety measures. By staying vigilant and proactive, you’ll steer clear of hazards and maintain smooth, compliant operations.

What Are the Best Practices for Preventing Fuel Theft?

To prevent fuel theft, you should implement strong security protocols like surveillance cameras, restricted access, and proper lighting around storage areas. Use theft deterrents such as lockable fuel caps, anti-siphon devices, and regular inventory checks. Train staff to spot suspicious activity and maintain detailed records of fuel transactions. Combining these measures creates a robust defense, discouraging theft and protecting your fuel supply effectively.

How Should Emergency Spill Response Equipment Be Maintained?

You should regularly inspect and maintain your emergency spill response equipment to guarantee it’s ready when needed. Focus on spill containment measures, checking for any damage or leaks, and replacing worn or outdated items. Keep all equipment clean and stored properly, and conduct routine drills to test functionality. Proper equipment maintenance guarantees quick, effective response during spills, minimizing environmental impact and ensuring safety for everyone involved.

Conclusion

By following this checklist, you become the hero safeguarding your fuel supply, much like a modern-day Odysseus steering treacherous waters. Stay vigilant, maintain diligent practices, and train your team—because preventing fuel issues isn’t just safety, it’s your voyage to uninterrupted operations. Keep these steps in mind, and you’ll steer clear of chaos, ensuring your fuel supply remains secure and reliable, no matter what storms may come.