To guarantee proper sizing of heat pumps and well pumps, you must adhere to local and national codes, accurately assess loads, and select equipment that matches your system’s needs. Avoid oversizing or undersizing, which can cause inefficiency or early failure. Follow electrical and plumbing standards, document your procedures, and verify performance during installation. Staying compliant with regulations helps your system operate safely and efficiently—continue to explore how these practices can optimize your setup.

Key Takeaways

- Always consult local building codes and standards to determine permissible pump sizes and installation requirements.

- Conduct accurate load calculations considering climate, insulation, and occupancy before selecting pump capacity.

- Verify pump performance through testing and efficiency measurements during commissioning to ensure compliance and optimal operation.

- Follow electrical and plumbing codes for wiring, grounding, and pipe sizing to ensure safety and regulatory adherence.

- Maintain thorough documentation of calculations, compliance checks, and testing results for future audits and troubleshooting.

Understanding Local and National Codes for Pump Sizing

Understanding local and national codes for pump sizing is vital to guarantee your heat pump or well pump operates efficiently and safely. These codes set standards that ensure the pump’s size aligns with safety, environmental, and performance requirements. Adhering to regulations helps maximize pump efficiency, reducing energy waste and operational costs. It also ensures proper system integration, preventing issues like over- or under-sizing that can harm your system’s performance. By familiarizing yourself with the relevant codes, you avoid penalties and costly modifications later. Compliance guarantees your pump functions as intended within the broader heating or water system, maintaining safety and reliability. Always check with local authorities and national guidelines to select a pump that meets all necessary codes for ideal system performance. Choosing the right inverter generator can ensure reliable power backup during outages or remote work.

Assessing Heating and Cooling Loads Accurately

To size your heat pump or well pump properly, you need to assess heating and cooling loads with accurate calculation methods. Consider climate variations in your area to guarantee your system can handle temperature extremes. Always verify that your load calculations meet local codes to stay compliant and avoid issues down the line. Additionally, understanding juice cleanses and detox benefits can help inform sustainable and health-conscious choices in your lifestyle.

Proper Load Calculation Methods

Accurately evaluating heating and cooling loads is essential for selecting the right size heat pump or well pump. Proper load calculation methods guarantee you don’t overestimate or underestimate your system’s needs. Start by gathering detailed data on your building’s insulation, windows, orientation, and occupancy patterns. Use established formulas or software tools designed for load calculations to determine precise heating and cooling requirements. This process helps you identify the correct pump sizing, preventing issues like short cycling or insufficient capacity. Remember, a proper load calculation isn’t just a step—it’s the foundation for efficient, compliant system performance. Skipping or rushing this step can lead to costly mistakes, energy waste, and system failures down the line. Accurate load assessment is your best insurance for a reliable, compliant installation. Proper load assessment ensures your system operates efficiently and meets industry standards.

Accounting for Climate Variations

Climate variations considerably impact your heating and cooling loads, making it essential to factor in local weather patterns during system design. Understanding the climate impact helps you account for regional variations in temperature extremes, humidity, and seasonal shifts. These factors influence how much heating or cooling your system needs to provide throughout the year. Ignoring regional climate differences can lead to undersized or oversized equipment, reducing efficiency and increasing costs. To guarantee accurate load assessments, incorporate climate data specific to your location, including historical temperature ranges and humidity levels. This approach ensures your heat pump or well pump system performs at its best, providing reliable comfort while complying with codes and standards tailored to your area’s climate impact.

Ensuring Code Compliance

Properly evaluating heating and cooling loads is essential for guaranteeing your system meets all relevant codes and standards. Accurate assessments help you select appropriately sized heat pumps and well pumps, preventing over- or under-sizing. Pay close attention to pump efficiency ratings, as higher efficiency units often meet stricter code requirements and save energy. Regular maintenance schedules are also vital; well-maintained equipment performs reliably and remains compliant with safety and efficiency standards. Ensure load calculations consider local climate variations and building specifics, as this directly impacts code compliance. Additionally, incorporating energy efficiency considerations into your assessments can lead to long-term savings and better system performance. By verifying your calculations and maintaining your systems diligently, you avoid penalties and guarantee optimal operation. Staying proactive with assessments guarantees your system remains compliant, efficient, and ready to meet your heating and cooling demands.

Selecting the Right Heat Pump Capacity for Your Space

Choosing the right heat pump capacity is essential to guarantee your space stays comfortable and energy-efficient. To do this, consider zoning considerations—how many areas you’ll heat or cool and their specific needs. Proper zoning ensures each space gets the right amount of heating or cooling without waste. Additionally, your aesthetic preferences matter; a larger capacity might mean bigger units that could impact your property’s appearance. You want a system that fits seamlessly into your space while providing ideal comfort. Too small, and you’ll struggle to maintain consistent temperatures; too large, and you’ll waste energy and cause frequent cycling. Assess your space’s size, insulation, and layout to determine the appropriate capacity. Consulting with a professional can help you select a unit that balances efficiency, comfort, and aesthetic appeal. Understanding the size and capacity requirements of your space is crucial for making an informed decision.

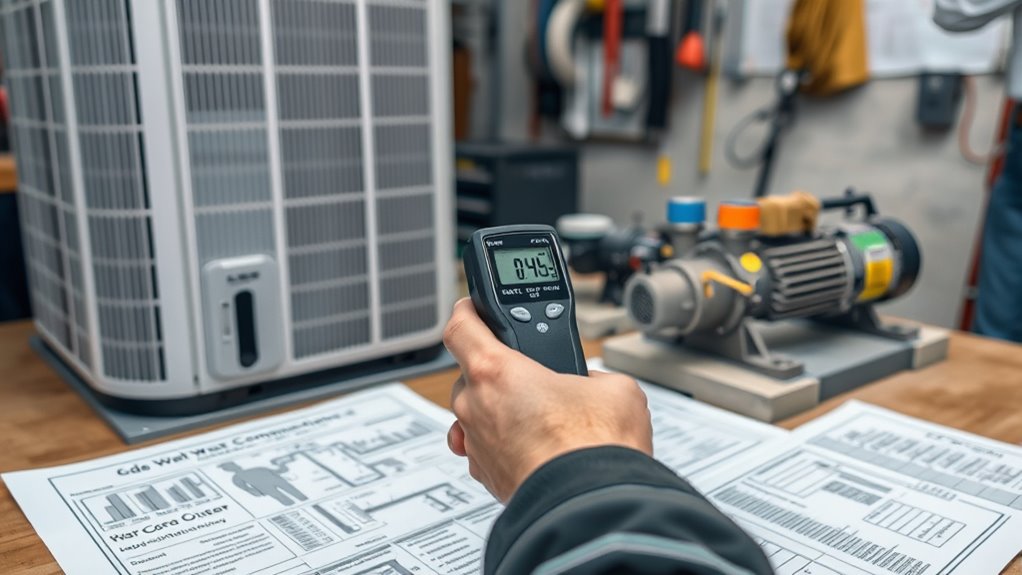

Proper Well Pump Sizing Based on Water Demand and Yield

How do you guarantee your well pump supplies enough water without wasting energy or causing damage? You need to size your pump based on your water demand and well yield. An undersized pump won’t meet your needs, while an oversize can cause cycling and damage. Calculate your daily water demand and compare it to your well’s yield to find the right size. Use the table below to help determine suitable pump sizes:

| Water Demand (GPM) | Well Yield (GPM) |

|---|---|

| 5-10 | 3-15 |

| 10-20 | 8-25 |

| 20-30 | 15-35 |

| 30+ | 25+ |

Matching water demand with well yield ensures efficient, reliable pump operation without waste or harm. Additionally, considering water quality and flow rate requirements can help optimize your system’s performance.

Avoiding Oversizing and Undersizing Pitfalls

To prevent sizing mistakes, you need to perform accurate load calculations that reflect your actual needs. It’s also essential to recognize common errors like overshooting capacity or underestimating demand. Following local code guidelines helps ensure your system is correctly sized and compliant. Be mindful of the tax implications associated with IRA withdrawals, as they can impact your overall retirement strategy and influence your financial planning.

Recognize Proper Load Calculations

Accurate load calculations are essential to guarantee your heat pump or well pump operates efficiently and reliably. Start with a thorough load assessment that considers factors like climate, insulation, and usage patterns. This helps determine the right system capacity, preventing oversizing or undersizing. Proper load assessment ensures you select equipment that matches your specific needs, avoiding energy waste and operational issues. Remember, oversizing can lead to short cycling and increased wear, while undersizing results in inadequate performance. Use detailed calculations and local codes to verify the load assessment’s accuracy. Recognizing proper load calculations is your first step toward compliant and effective sizing, ensuring your system performs at its best over its lifespan. Incorporating aesthetic wall organization solutions can also help optimize space and improve maintenance access around your equipment.

Avoid Common Sizing Errors

Preventing sizing errors is essential to guarantee your heat pump or well pump functions efficiently and lasts longer. Oversizing can lead to short cycling, reducing pump efficiency and increasing wear on system components. Conversely, undersizing causes inadequate performance, forcing the pump to work harder and risking early failure. To avoid these pitfalls, always base your sizing on accurate load calculations and proper data analysis. Properly sized systems enhance pump efficiency and promote system longevity by minimizing unnecessary strain. Remember, a correctly sized pump operates smoothly, conserves energy, and reduces maintenance costs. Additionally, understanding the correct sizing techniques can significantly improve system performance and lifespan. Avoid guesswork and rely on detailed assessments to ensure your system is neither too big nor too small—just right for peak performance and durability.

Follow Local Code Guidelines

Following local code guidelines is a key step in guaranteeing your heat pump or well pump is correctly sized. These codes are designed to promote pump efficiency and energy conservation, preventing oversizing or undersizing. To stay compliant, focus on these factors:

- Verify that your pump meets local capacity and safety standards, which help optimize energy use.

- Consult local building codes to determine maximum and minimum pump sizes, avoiding unnecessary energy consumption.

- Use code-approved methods for load calculations to ensure your pump is neither oversized—wasting energy—nor undersized, risking inadequate performance.

- Be aware that local hours for retail stores like Ulta Beauty or Sephora can influence when you might visit suppliers or service providers for pump installation or maintenance, ensuring your project aligns with local schedules.

Adhering to these guidelines ensures your system operates efficiently, reduces energy costs, and complies with local regulations. Proper sizing ultimately enhances pump lifespan and performance.

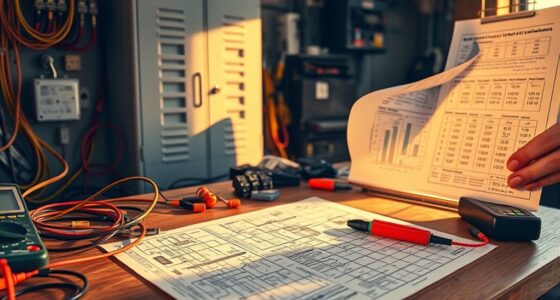

Ensuring Compliance With Electrical and Plumbing Standards

To guarantee your heat pump or well pump installation meets all necessary requirements, you need to carefully adhere to local electrical and plumbing standards. Ensuring electrical safety is critical; verify proper wiring, grounding, and circuit protection to prevent hazards. Follow plumbing regulations to ensure correct pipe sizing, connections, and backflow prevention, protecting water quality and system efficiency. Check that all electrical components comply with national and local codes, including breaker sizes and disconnects. For plumbing, use approved materials and adhere to installation depths and spacing requirements. Staying compliant minimizes the risk of code violations, system failures, and safety hazards. Regularly consult local building departments or inspectors to confirm your setup aligns with current standards, ensuring a safe, reliable, and code-conformant installation.

Documenting and Verifying Proper Sizing Procedures

Accurate documentation and verification of sizing procedures are key to ensuring your heat pump or well pump operates efficiently and safely. Proper records help confirm that the pump’s capacity matches system demands and that pump efficiency is optimized. To achieve this, you should:

- Record detailed calculations and data sources used during sizing, including load estimates and pump specifications.

- Confirm pump performance through flow rate tests and efficiency measurements during initial startup.

- Establish maintenance practices that regularly monitor pump operation, ensuring sustained efficiency and early detection of sizing issues.

Thorough documentation allows for troubleshooting, future upgrades, and compliance audits. Verifying proper sizing ensures your system runs smoothly, reduces energy costs, and prolongs equipment lifespan.

Common Mistakes to Avoid During Installation and Sizing

Installing and sizing heat pumps and well pumps can be complex, and overlooking common mistakes can lead to inefficiency, higher costs, or equipment failure. One mistake to avoid is neglecting proper pump efficiency ratings; choosing undersized or oversized pumps reduces efficiency and increases energy bills. Another critical error is ignoring maintenance scheduling during installation—failing to plan for regular upkeep can cause premature failure and costly repairs. Improperly sizing pumps based on inaccurate data can also lead to inconsistent performance and higher operational costs. Additionally, neglecting manufacturer guidelines or local code requirements can result in non-compliance and future legal issues. By paying close attention to pump efficiency and establishing a clear maintenance schedule, you guarantee ideal performance and long-term reliability.

Staying Updated With Code Changes and Industry Best Practices

Keeping up with current code requirements and industry standards guarantees your installations remain compliant and efficient. Regularly reviewing updates guarantees you meet environmental impact regulations and adhere to manufacturer guidelines. To stay informed:

- Subscribe to industry newsletters and official code updates to catch changes early.

- Attend training sessions and industry conferences focused on best practices and new regulations.

- Consult manufacturer guidelines regularly to align your work with their latest recommendations for safety and performance.

Frequently Asked Questions

How Do Local Codes Differ From National Standards for Pump Sizing?

Local regulations often set specific requirements for pump sizing based on regional factors like climate and water availability, while national standards provide broader guidelines meant for general application. You need to verify your pump meets local regulations first, as they might be stricter or have unique specifications. Always check regional standards to ensure compliance, but remember that local codes take precedence and might differ markedly from national standards.

What Are the Signs of Incorrect Pump Sizing During Operation?

You’ll notice incorrect pump sizing when it keeps making excessive noise or drinks up energy like it’s on a binge. Pump noise becomes a constant annoyance, and energy bills skyrocket, proving the pump is either overworked or struggling. If your system seems louder than it should or your energy consumption spikes unexpectedly, it’s a clear sign that your pump isn’t properly sized, and it’s time for a professional check.

How Often Should Pump Sizing Procedures Be Reviewed or Updated?

You should review your pump sizing procedures at least annually. Incorporate maintenance schedules and performance testing to guarantee ideal operation. Regular assessments help identify if your pump remains appropriately sized as system demands change over time. Updating procedures based on test results and maintenance data keeps your system efficient and compliant. Don’t wait for issues to arise—proactive reviews safeguard performance and longevity of your heat and well pumps.

Are There Specific Certifications Required for Technicians Performing Sizing?

Did you know that 85% of successful system installations depend on proper technician certifications? For sizing, you need technicians certified in relevant standards like NATE or HVAC Excellence. These certifications ensure they understand sizing standards and can accurately assess system requirements. Always verify that technicians hold the appropriate certifications before trusting them with sizing procedures, as this guarantees compliance and ideal performance of heat and well pumps.

How Can I Verify That My Pump Installation Meets All Compliance Requirements?

You can verify your pump installation meets compliance requirements by inspecting for proper installation of pump efficiency standards and ensuring it aligns with local codes. Check that your maintenance schedules are up-to-date and documented, as this illustrates ongoing compliance. Consult with a certified inspector or review manufacturer guidelines to confirm all aspects of the installation adhere to regulations, ensuring safe, efficient operation.

Conclusion

By understanding and following the right sizing practices, you’ll navigate the code landscape like a seasoned sailor steering clear of hidden reefs. Accurate assessments and adherence to standards guarantee your heat and well pumps perform efficiently without wasting resources. Keep up with industry updates, document your steps, and avoid common pitfalls. When you do, you’ll keep your system running smoothly—like a well-oiled machine—protecting your investment and ensuring comfort for years to come.