To guarantee safety and proper operation, you need to ground your generator’s neutral point directly to earth using a grounding electrode. Bonding all metallic parts like enclosures and frames is vital for creating a continuous low-resistance path. This allows fault currents to safely divert and prevents shock hazards. Proper installation and verification are key to effective grounding and bonding, so if you want to learn more about best practices, there’s plenty of essential details to explore.

Key Takeaways

- Connect the generator’s neutral point directly to an earth ground using proper grounding electrodes.

- Ensure bonding conductors securely connect all metallic parts and enclosures to maintain a continuous low-resistance path.

- Verify proper grounding and bonding practices during installation to enhance system safety and fault response.

- Use low-resistance grounding methods to stabilize voltage and facilitate safe fault current dissipation.

- Regularly inspect and maintain grounding and bonding connections to prevent electrical shock hazards and equipment damage.

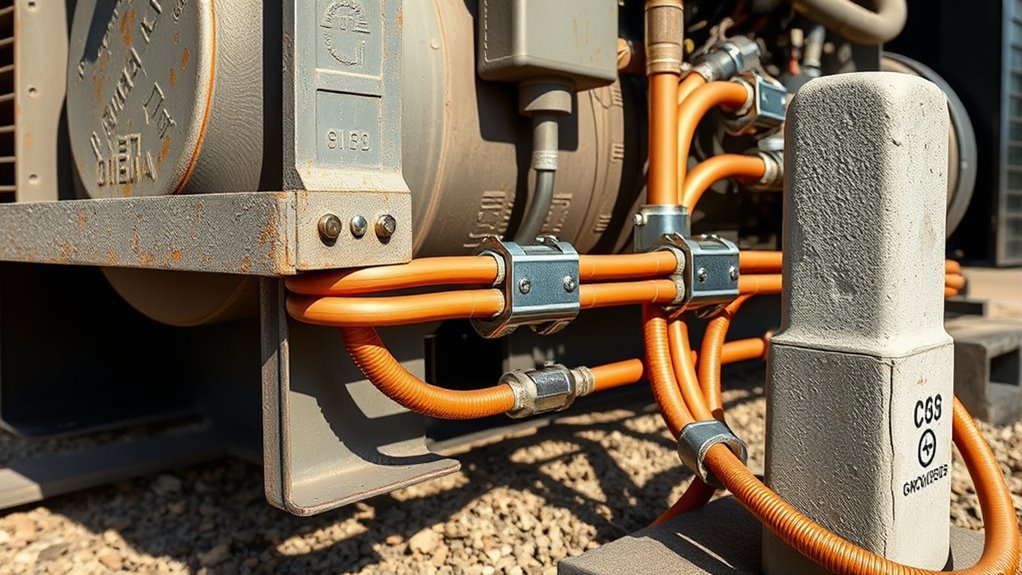

Have you ever wondered why proper grounding and bonding are indispensable for generators? When you’re operating a generator, ensuring it’s correctly grounded isn’t just a safety measure—it’s critical for protecting people and equipment. One key aspect of this process involves neutral grounding, which connects the generator’s neutral point to earth ground. This connection helps stabilize voltage levels and provides a clear path for fault currents, reducing the risk of electrical shock or equipment damage. Without proper neutral grounding, you could face unpredictable voltage fluctuations or dangerous electrical faults that may go unnoticed until they cause serious problems. It’s important to use the right grounding methods, such as grounding the neutral directly to a grounding electrode, ensuring that the system has a low-resistance path to earth and that fault currents are safely directed away from workers and sensitive equipment. Proper grounding also helps prevent electrical shock hazards and enhances overall system safety.

In addition to neutral grounding, bonding conductors play a pivotal role in maintaining electrical safety. Bonding conductors connect various metallic parts, such as enclosures, frames, and other conductive components, to create a continuous, low-resistance path to ground. This ensures that if a fault occurs—say, a live wire touches a metal frame—current can quickly flow back to the source, triggering protective devices like circuit breakers or fuses to shut down the system. Proper bonding prevents potential differences between conductive parts, which could otherwise lead to electrical shock hazards. When you’re setting up your generator, it’s essential to verify that bonding conductors are correctly installed and continuous throughout the system. This involves attaching bonding conductors securely to all metal parts that might become energized during a fault, ensuring a reliable ground path and minimizing shock risks.

Frequently Asked Questions

How Often Should Generator Grounding Systems Be Inspected?

You should inspect your generator’s grounding system at least annually to guarantee compliance with grounding standards. Regular inspections help identify corrosion, loose connections, or damage that could compromise safety and performance. If your generator operates in harsh environments or frequently experiences heavy use, consider increasing inspection frequency to every six months. Adhering to recommended inspection schedules maintains proper grounding, prevents electrical hazards, and ensures your generator functions reliably when needed.

Are Portable Generators Required to Be Grounded Differently?

Yes, portable generators require different grounding methods. You should use portable grounding techniques, such as grounding rods or a grounding wire, to guarantee safety. Proper generator bonding involves connecting the frame to the grounding system, preventing electrical shock. Always follow manufacturer instructions and local codes for portable grounding and bonding practices. This helps protect you and maintains safe operation during power outages or remote work.

What Are the Common Mistakes in Generator Bonding?

Did you know that improper bonding causes over 30% of generator-related electrical issues? One common mistake is neglecting to properly connect the neutral to the grounding conductor, which can lead to unsafe conditions. Always make certain your generator’s neutral connection is correctly bonded or floating, depending on the setup. Failing to verify these connections can create shock hazards or damage equipment, so double-check your grounding conductors and neutral connections before use.

How Does Grounding Affect Generator Transfer Switch Operation?

Grounding directly impacts your transfer switch’s operation by ensuring proper transfer switch compatibility and reliable ground fault detection. When your generator is correctly grounded, it prevents false alarms and misoperation during switching, ensuring seamless power transfer. Proper grounding also helps the transfer switch detect faults quickly, protecting your system and maintaining safety. Without correct grounding, the transfer switch may malfunction or fail to identify issues, risking damage or safety hazards.

Can Grounding Requirements Vary by State or Local Code?

Imagine your generator as a steady lighthouse, guiding safety through unpredictable storms. Your state’s regulations and local codes act as the lighthouse keeper, shaping how grounding is established. These rules can vary, like different lighthouse signals guiding ships differently. So, you must check both state and local codes to ensure your grounding meets specific requirements, keeping your setup safe and compliant regardless of where you are.

Conclusion

Proper grounding and bonding for your generator are essential, like roots anchoring a mighty tree, ensuring safety and reliable operation. By following the code requirements and best practices, you protect yourself and your equipment from electrical faults. Remember, neglecting these steps is like leaving a ship without an anchor—vulnerable to storms. Stay informed, stay safe, and keep your system grounded and bonded correctly for peace of mind and dependable power whenever you need it.