To avoid common mistakes in natural gas line sizing, you need to verify accurate gas flow calculations, consider pressure drops and line length, and select up-to-date charts and standards. Don’t forget to follow local codes, choose proper materials, and plan for future expansion. Environmental factors and elevation also impact design. Skipping permits or rushing measurements can compromise safety and efficiency. Stay aware of these pitfalls, and you’ll build a safer, more reliable gas line system. More insights await if you keep exploring.

Key Takeaways

- Conduct accurate flow calculations and proper measurements to determine correct pipe size and prevent pressure issues.

- Select appropriate materials, fittings, and safety features to ensure system integrity and prevent leaks.

- Follow current standards, codes, and obtain necessary permits to ensure legal compliance and safety.

- Plan for future growth and environmental factors to avoid undersized pipelines and performance problems.

- Consider environmental conditions like elevation, temperature, and humidity to enhance pipeline durability and safety.

Neglecting to Calculate Proper Gas Flow Requirements

If you skip calculating the proper gas flow requirements, your gas line may be undersized or oversized, leading to problems. Properly evaluating flow measurement is essential to determine the amount of gas your system needs. Without accurate flow measurement, you won’t know the necessary gas pressure to maintain safe and efficient operation. An undersized line can restrict flow, causing pressure drops and inconsistent supply, while an oversized line wastes materials and increases costs. To avoid these issues, you must understand your system’s demand, including peak flow rates. This ensures you select a line with the right diameter and pressure capacity. Correct calculations help maintain steady gas pressure and reliable flow, preventing potential safety hazards and operational inefficiencies down the line. Additionally, incorporating essential oil benefits knowledge can promote safety and efficiency in related systems by reducing stress and improving overall operational well-being.

Overlooking Pressure Drop and Line Length Factors

You need to contemplate how longer gas lines increase pressure drop, which can reduce flow and cause operational issues. Even small increases in line length can considerably impact pressure, especially if you ignore this factor. Understanding how line length affects pressure drop helps you size your pipes accurately and avoid costly mistakes. Additionally, considering sound vibrations and their influence on pipeline integrity can further enhance safety and efficiency.

Line Length Impact

One common mistake in natural gas line sizing is neglecting the impact of line length on pressure drop. As the length of your gas pipe increases, pressure drops more notably, which can reduce flow efficiency. You might overlook how pipe diameter affects this, since a smaller diameter increases resistance over long distances. Additionally, material compatibility plays a role; some materials cause more friction or corrosion, further impacting pressure and flow. When you underestimate the effect of line length, your system may not deliver sufficient gas pressure, leading to performance issues or safety concerns. Always consider how long your pipeline is, select the correct pipe diameter, and ensure the material suits your application to prevent problems down the line. Moreover, understanding water park features can help in planning effective infrastructure that handles pressure and flow efficiently.

Pressure Drop Significance

Neglecting the significance of pressure drop in natural gas line sizing can lead to serious performance issues. When you ignore pressure loss, your system may experience reduced flow rates or inconsistent delivery, causing appliances to underperform. Properly accounting for pressure drop helps determine the right pipe diameter; a smaller diameter increases pressure loss, while a larger one minimizes it. If you overlook this factor, you risk selecting a pipe that’s too narrow, leading to excessive pressure loss over the line’s length. This can cause insufficient gas flow and operational problems. Conversely, oversizing increases costs unnecessarily. To avoid these issues, always consider the pressure drop associated with your line length and pipe diameter, ensuring your natural gas system functions safely and efficiently.

Using Incorrect or Outdated Sizing Charts and Tables

Using outdated or incorrect sizing charts and tables can lead to serious issues in natural gas line installation. Relying on obsolete data may cause under-sizing or over-sizing, risking gas regulator malfunctions or insufficient ventilation requirements. Always confirm your charts reflect current standards and local codes. Misjudging pipe diameter can cause pressure drops or buildup, creating safety hazards. Keep in mind that proper sizing supports ideal gas flow and safety. Additionally, understanding headphone compatibility can help prevent unnecessary equipment issues when integrating new components.

Ignoring Local Code and Regulation Compliance

Failing to adhere to local codes and regulations when installing or modifying natural gas lines can lead to legal penalties, safety hazards, and future liability. Ensuring code compliance and regulation adherence isn’t optional—it’s essential for safe, legal operation. Ignoring these requirements might save time initially but can cause costly fines or forced rework later. Local codes specify minimum standards for pipe sizing, installation practices, and safety measures that protect both you and others. Always verify the relevant regulations before starting work. Proper regulation adherence ensures your installation meets safety standards and reduces the risk of leaks, explosions, or legal issues. Additionally, understanding installation standards and how they apply to your project can prevent many common mistakes. Don’t overlook the importance of compliance; it’s a critical step in responsible and safe natural gas line sizing.

Choosing Material and Fittings Without Considering Gas Flow

Choosing the right material and fittings is essential because selecting incompatible or substandard components can disrupt gas flow and compromise safety. Ignoring proper material selection and fitting compatibility risks leaks, pressure drops, and system failure. To avoid this, you must consider:

- Material strength and corrosion resistance—using unsuitable materials can lead to deterioration over time.

- Fitting compatibility—ensure fittings match your pipe material and size to prevent leaks.

- Flow efficiency—select fittings designed for *ideal* gas flow, reducing pressure loss.

Failing to evaluate these factors can cause dangerous malfunctions and costly repairs. Always verify that your chosen materials are approved for gas lines and that fittings are compatible with your pipe type and size. Proper consideration safeguards both safety and system performance.

Failing to Include Proper Venting and Safety Measures

Neglecting proper venting and safety measures can lead to dangerous pressure buildup and the release of hazardous gases. You must prioritize ventilation requirements to prevent gas accumulation in enclosed spaces, which can cause explosions or health hazards. Ensure that your system includes adequate vents, exhausts, and alarms, following established safety protocols. Failure to implement these measures increases the risk of gas leaks going unnoticed and pressure-related failures. Always verify that ventilation meets local codes and standards, and incorporate safety features like shut-off valves and gas detectors. Addressing venting requirements and safety protocols isn’t optional—it’s essential for a safe, reliable natural gas line system. Proper planning and adherence to safety measures protect both your property and its occupants from potential disasters. Additionally, understanding AI security vulnerabilities can help in implementing better safety measures for automated monitoring systems.

Underestimating Future Expansion or Appliance Additions

When planning your natural gas line, it’s easy to overlook future expansion or additional appliances that might be needed down the road. Ignoring future growth can lead to costly upgrades later. Consider these critical points:

- You might want to add a new stove, heater, or fireplace, increasing demand on your gas supply.

- Future appliance additions could require larger or additional lines, or even rerouting, which complicates your initial setup.

- Underestimating this growth risks inadequate pressure, causing poor appliance performance or safety hazards.

Skipping the Necessary Permits and Inspections

Have you considered the importance of obtaining the proper permits and scheduling inspections for your natural gas line? Skipping permit compliance can lead to costly fines and project delays. Permits ensure your installation meets local safety codes and standards, reducing hazards. Ignoring inspection protocols risks undetected issues that could cause leaks or accidents later. Always check with local authorities before starting work to understand required permits. Schedule inspections at key stages of installation to verify compliance and safety. Failing to do so might invalidate your work, void warranties, or cause future legal problems. Proper permits and inspections aren’t just bureaucratic steps—they’re essential safeguards for your safety, your property, and your peace of mind. Understanding local regulations is crucial to ensure your project remains compliant and safe. Don’t cut corners—respect the process to ensure a safe, compliant natural gas line.

Misjudging the Impact of Elevation and Environmental Conditions

You might overlook how elevation changes can affect gas flow, leading to undersized or oversized lines. Environmental conditions like temperature, humidity, and wind also impact the line’s performance and safety. Ignoring these factors can cause significant sizing mistakes that compromise efficiency and safety. Additionally, understanding how signs of spoilage in related substances can influence safety protocols emphasizes the importance of comprehensive planning.

Elevation Effects on Flow

Elevation and environmental conditions markedly influence natural gas flow, yet many overlook their true impact when sizing pipelines. Ignoring these factors can lead to serious issues like unexpected pressure fluctuation and inefficient flow. Consider these risks:

- Overestimating pressure needs—causing oversized, costly pipelines.

- Underestimating temperature variation—leading to flow restrictions.

- Failing to account for elevation changes—resulting in pressure drops that hinder supply.

As altitude increases, the gas’s pressure can drop, affecting flow rates. Environmental factors also cause temperature variations that impact gas density and pressure. These subtle shifts can cause significant flow disruptions if not properly considered. Always evaluate elevation effects carefully, ensuring your pipeline design compensates for pressure fluctuation and temperature change to maintain safe, reliable delivery. Additionally, understanding the flow dynamics within the pipeline helps optimize design and prevent operational issues.

Environmental Factors Influence Sizing

Environmental conditions such as temperature fluctuations, humidity, and exposure to elements substantially affect natural gas pipeline performance. When weather varies, soil stability can change, impacting the pipeline’s support and integrity. Extreme temperatures cause gas pressure and flow rates to fluctuate, requiring adjustments in line sizing. Humid conditions may lead to corrosion, especially if the environment exposes the pipe to moisture and corrosive elements. You must consider how weather variations influence soil stability, which influences the pipeline’s foundation and overall safety. Leveraging automation in data analysis can help monitor environmental impacts more effectively. Failing to account for these environmental factors can lead to underestimating necessary pipe diameter or pressure ratings. Properly evaluating how temperature, humidity, and soil stability interact ensures your gas line is resilient, efficient, and safe under all environmental conditions.

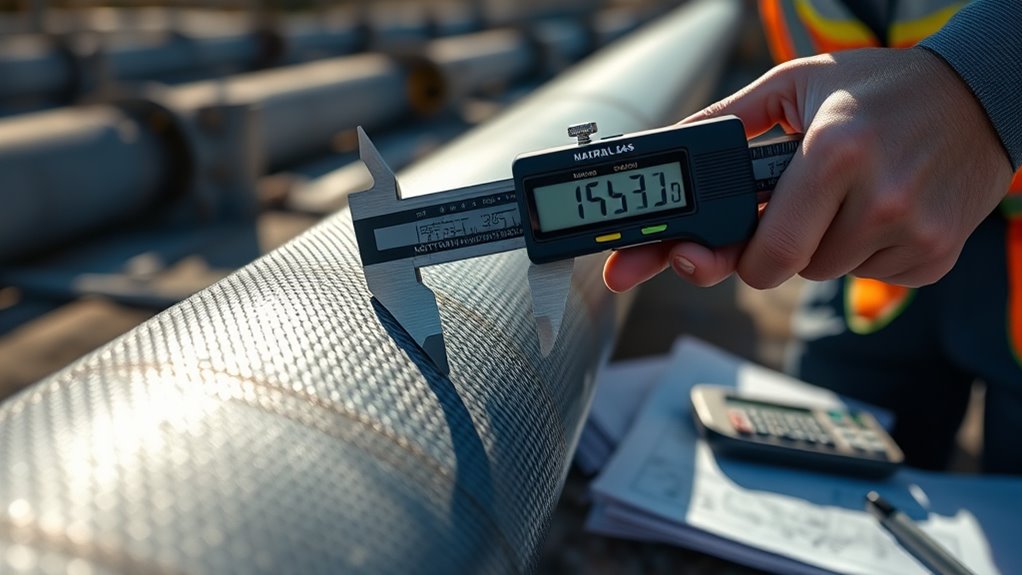

Rushing the Planning Phase Without Accurate Measurements

Skipping or rushing through the planning phase without obtaining precise measurements can lead to significant mistakes in gas line sizing. Inaccurate measurement accuracy compromises the entire planning process, risking under or over-sizing your gas line. This can cause safety hazards, system inefficiencies, or costly repairs down the line. To avoid these pitfalls, focus on these critical points:

Accurate measurements are essential to prevent costly gas line sizing errors and ensure safety and efficiency.

- Neglecting detailed measurements can lead to incorrect flow calculations.

- Ignoring pressure drops and other environmental factors during measurement.

- Rushing the planning process without verifying all data, resulting in flawed decisions.

Taking the time to gather accurate measurements ensures your planning process is solid, reducing the risk of costly errors. Precision here directly impacts the safety, efficiency, and longevity of your natural gas system.

Frequently Asked Questions

How Do I Determine the Correct Gas Flow Rate for My System?

To determine the correct gas flow rate, perform a gas flow calculation based on your system’s needs, considering appliances and their BTU ratings. Use sizing charts to find the appropriate pipe size and flow rates, ensuring safety and efficiency. Measure or estimate the total gas demand accurately, then consult charts to match flow rates with pipe dimensions. This approach helps you avoid undersizing or oversizing your natural gas line.

What Tools Are Best for Measuring Line Length and Elevation Changes?

A stitch in time saves nine, so get it right from the start. For measuring line length and elevation changes accurately, use reliable measuring devices like tape measures or laser distance meters. Elevation tools such as digital inclinometers or spirit levels help you gauge vertical changes precisely. Combining these tools ensures you gather accurate data, preventing sizing errors that could cause inefficiencies or safety issues in your natural gas line system.

How Often Should I Update or Verify Sizing Charts and Tables?

You should update or verify your sizing charts and tables annually, especially during regular maintenance schedules. This guarantees material compatibility and accounts for any changes in regulations or standards. Regular reviews help catch any discrepancies or outdated data, maintaining safety and efficiency. If you notice significant changes in gas demand or system upgrades, update more frequently to keep your system properly sized and compliant.

Are There Specific Local Codes That Override General Gas Line Sizing Rules?

Yes, local regulations can override general gas line sizing rules. You need to check specific local codes because they often include requirements tailored to your area’s safety and infrastructure standards. Confirm your work complies with these local regulations to maintain code compliance. Ignoring local codes can lead to safety hazards or legal issues, so always verify with your local authority or building department before finalizing your gas line sizing.

What Safety Features Are Essential for Long-Term Gas Line Operation?

You should prioritize safety features like gas leak detection systems and corrosion protection for long-term gas line operation. Gas leak detectors quickly alert you to potential hazards, preventing accidents. Corrosion protection guarantees the pipe’s integrity over time, avoiding leaks and failures. Combining these features helps maintain a safe, reliable gas supply, giving you peace of mind and reducing maintenance costs. Regular inspections further enhance safety and longevity.

Conclusion

By avoiding these common pitfalls, you’ll guarantee your natural gas line is safe, efficient, and up to code—avoiding a potential Pandora’s box of issues. Remember, thorough planning and proper calculations are your best allies, much like a trusty compass on a treacherous voyage. Don’t rush or overlook details; even the most seasoned explorers know that precision now prevents chaos later. Stay diligent, and your project will stand the test of time, just like a well-built cathedral.