To avoid common mistakes in generator ventilation and clearances, make certain you don’t block exhaust outlets or vents, as this can cause dangerous buildup. Always follow manufacturer guidelines for proper placement and maintain adequate space around the generator for ventilation. Regularly inspect and maintain ventilation systems to prevent damage and blockages. Keep safe distances from structures and windows to prevent fumes from entering enclosed spaces. Staying aware of these tips helps ensure safe, efficient operation—continue if you want to learn more.

Key Takeaways

- Ensure generators are placed in well-ventilated outdoor areas, maintaining proper clearances from walls, windows, and vents.

- Regularly inspect and maintain ventilation systems, including ducts and exhaust outlets, to prevent blockages and damage.

- Avoid covering or obstructing exhaust outlets and vents with debris, furniture, or landscaping materials.

- Follow manufacturer guidelines for clearance distances and placement to prevent safety hazards and code violations.

- Maintain sufficient space around the generator to allow unobstructed airflow and prevent overheating or fume buildup.

Blocking Exhaust Outlets and Vents

Blocking exhaust outlets and vents can be a serious mistake when operating a generator. When airflow obstruction occurs, hot gases and fumes can’t escape properly, creating dangerous buildup. Proper vent placement is vital; vents should be positioned away from windows, doors, or other openings to prevent exhaust from re-entering your space. Obstructing vents or exhaust outlets can lead to reduced engine efficiency and increased risk of carbon monoxide buildup. Always make sure there’s enough clearance around exhaust outlets, and avoid covering vents with debris, furniture, or landscaping. Additionally, understanding generator ventilation principles is essential for safe operation. By maintaining clear pathways and strategic vent placement, you help keep exhaust gases safely vented away, protecting both your equipment and your health. Proper ventilation is indispensable for safe, reliable generator operation.

Ignoring Manufacturer Clearance Recommendations

Ignoring manufacturer clearance recommendations can lead to improper ventilation and potential safety hazards. You might risk violating building codes or safety standards by not maintaining the proper distance requirements. Ensuring you follow these guidelines helps keep your generator operating safely and reliably. Additionally, inadequate clearance can impact the generator’s performance and longevity by restricting airflow and increasing the risk of overheating proper ventilation.

Proper Distance Requirements

Many installers underestimate the importance of maintaining proper distance from the generator when setting it up, which can lead to safety hazards and efficiency issues. Ignoring clearance guidelines compromises ventilation, risking overheating and poor airflow. To guarantee ideal generator placement, follow established distance requirements. Imagine:

- A generator too close to a wall, trapping exhaust fumes

- Obstructed airflow due to nearby debris or structures

- Insufficient space for maintenance or repairs

- Exhaust gases lingering near windows or vents

- Overcrowded setup that blocks ventilation outlets

Maintaining proper distances enhances safety, prevents damage, and ensures efficient operation. Always adhere to clearance guidelines, avoiding shortcuts that could jeopardize your installation’s performance. Proper generator placement isn’t just about compliance; it’s essential for longevity and safety. Proper ventilation is critical to prevent buildup of dangerous gases and maintain optimal performance.

Risk of Code Violations

Failing to follow manufacturer clearance recommendations can lead to serious code violations that jeopardize your installation’s legality and safety. Ignoring these guidelines might cause your setup to fail inspections, resulting in costly modifications or shutdowns. Proper clearances are essential for maintaining peak fuel efficiency, as inadequate spacing can cause the generator to work harder, reducing performance. Additionally, insufficient clearances often increase noise levels, making your generator more disruptive. By adhering to manufacturer specifications, you ensure your generator operates efficiently and quietly, while also complying with local codes. Neglecting these recommendations puts your investment at risk and could lead to safety hazards. Always prioritize manufacturer clearance guidelines to avoid violations and ensure your generator runs smoothly, efficiently, and safely. Implementing safety standards and best practices can further help prevent potential issues.

Ensuring Safe Operation

Neglecting manufacturer clearance recommendations can substantially compromise the safe operation of your generator. When clearances are ignored, you risk overheating, increased noise levels, and reduced fuel efficiency. Proper spacing ensures adequate airflow, preventing heat buildup and maintaining ideal performance. Imagine a crowded, poorly ventilated space where noise reverberates loudly, and the engine struggles to breathe. Without enough clearance:

- Exhaust gases linger, raising fire hazards

- Airflow is obstructed, decreasing fuel efficiency

- Noise escapes unchecked, disturbing surroundings

- Overheating causes component failure

- Ventilation gaps are blocked, risking carbon monoxide buildup

Ensuring proper generator ventilation helps you reduce noise, improve fuel efficiency, and keep your generator operating safely. Clearances aren’t just rules—they’re essential for safe, efficient, and quiet generator operation.

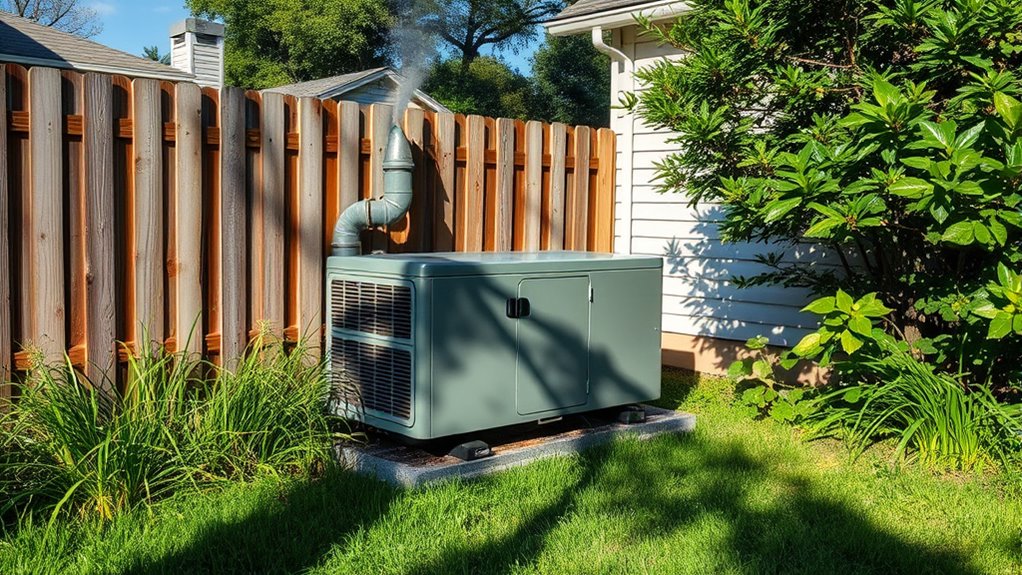

Improper Placement of the Generator

Placing your generator in the wrong location can lead to dangerous health risks and operational issues. Proper site specific planning is essential to guarantee your generator is positioned safely and efficiently. Avoid spots that block airflow or are too close to windows, vents, or occupied spaces, as this can cause exhaust fumes to infiltrate your building. Aesthetic considerations also matter; placing the generator where it’s visible or disruptive can affect your property’s appearance. Think about accessibility for maintenance and proximity to fuel sources, but prioritize safety over convenience. Improper placement can cause noise issues, exhaust buildup, and potential health hazards. Take the time to evaluate your site carefully to position your generator in a way that balances safety, functionality, and visual impact. Ensuring proper ventilation and clearances is crucial to prevent the accumulation of harmful fumes and maintain optimal generator performance.

Overlooking Proper Ventilation Space

You need to leave enough space around your generator to prevent airflow blockages. Without proper clearance, exhaust gases can build up, creating safety hazards. Ensuring safe exhaust flow and ventilation is essential for reliable operation. Additionally, maintaining adequate ventilation space helps reduce the risk of overheating and prolongs the lifespan of your generator.

Adequate Clearance Essential

Making certain there’s enough clearance around your generator is essential for proper ventilation and safe operation. Proper generator placement guarantees ventilation gaps are maintained, preventing overheating and dangerous exhaust buildup. If clearance is too tight, heat and gases can accumulate, risking damage or failure. You need open space to allow fresh air to flow in and exhaust to escape freely. Visualize a well-ventilated setup with ample room on all sides, unobstructed airflow, and unobstructed access for maintenance.

- Space between generator and walls

- Unblocked airflow pathways

- Sufficient room for exhaust dispersion

- Clear access for inspection and repairs

- No nearby objects that trap heat or fumes

Prevents Ventilation Blockages

Failing to leave adequate space around your generator can easily lead to ventilation blockages. Without proper clearance, airflow enhancement becomes impossible, causing hot air and fumes to accumulate instead of dispersing efficiently. Poor ventilation design restricts the movement of fresh air in and hot air out, increasing the risk of overheating and damage. Ensuring enough space allows air to circulate freely, reducing obstruction risks and maintaining ideal operating conditions. Regularly check clearances and avoid clutter near your generator, as debris or tight spaces can compromise airflow. Proper ventilation space isn’t just about safety; it’s essential for reliable performance and longevity. Additionally, automation technologies can help monitor and optimize ventilation systems to prevent blockages proactively. By prioritizing sufficient clearance, you prevent ventilation blockages and support effective heat dissipation, keeping your generator running smoothly.

Ensures Safe Exhaust Flow

When proper ventilation space isn’t maintained around your generator, exhaust gases can accumulate and pose serious safety risks. Insufficient clearance can cause dangerous buildup, reducing fuel efficiency and increasing noise levels. To guarantee safe exhaust flow, keep ample space around the unit, allowing gases to vent freely. Proper ventilation is essential for preventing harmful fume buildup and ensuring safe operation.

Imagine:

- Hot gases escaping smoothly without obstruction

- Reduced buildup of harmful fumes

- Less strain on your generator, improving fuel efficiency

- Quieter operation due to proper airflow

- Lower risk of exhaust-related fire hazards

Maintaining adequate clearance not only enhances safety but also optimizes performance. Proper ventilation prevents blockages that can lead to costly repairs and ensures your generator runs efficiently, quietly, and safely.

Using Inadequate or Damaged Ventilation Systems

Using inadequate or damaged ventilation systems can considerably compromise generator safety and efficiency. When your ventilation system isn’t functioning properly, heat and exhaust gases may not vent correctly, increasing the risk of overheating or dangerous fumes building up. neglecting to follow proper clearance guidelines can restrict airflow, further reducing cooling effectiveness. Inspect your ventilation system regularly to identify any damage, blockages, or wear that could impair airflow. Damaged ducts, loose fittings, or clogged vents hinder proper exhaust removal and cooling, putting your generator at risk. Always guarantee your ventilation setup meets the manufacturer’s specifications and clearance guidelines. Proper ventilation isn’t just about placement—it’s essential for maintaining safe operation and preventing costly downtime or accidents. Ensuring your airless paint sprayer is properly maintained can help prevent similar issues with equipment airflow and performance.

Neglecting Regular Maintenance and Inspection

Neglecting regular maintenance and inspection can lead to unnoticed issues that jeopardize your generator’s safety and performance. Without routine inspections and scheduled maintenance, problems like clogged filters, worn belts, corrosion, or loose connections may go unnoticed until they cause failure. These small issues can reduce airflow, increase emissions, or lead to overheating. By skipping these steps, you risk costly repairs and dangerous malfunctions.

Imagine dust buildup on vents, frayed wiring, oil leaks, rusted components, or debris blocking air pathways—all signs that maintenance is overdue. Regularly checking these elements ensures your generator runs efficiently and safely, preventing problems before they escalate. Don’t underestimate the importance of consistent inspections and scheduled maintenance to keep your generator operating smoothly.

Failing to Create a Safe Distance From Structures and Windows

Failing to maintain a safe distance between your generator and nearby structures or windows can lead to dangerous buildup of carbon monoxide and other exhaust gases. Your generator location is critical; placing it too close to windows or vents can allow toxic fumes to enter indoor spaces or enclosed areas. Follow ventilation guidelines carefully, ensuring at least the recommended clearance distances from walls, windows, and openings. This prevents exhaust gases from accumulating and reduces health risks. Always position your generator in a well-ventilated outdoor area, away from windows, doors, and vents. Ignoring these precautions can compromise safety and violate local codes. Proper placement not only protects you but also ensures your generator operates efficiently and safely. Remember, clearances and ventilation are key to safe generator use.

Frequently Asked Questions

How Do Weather Conditions Affect Generator Ventilation Safety?

Weather conditions critically impact ventilation safety for your generator. Heavy rain or snow can block vents or cause moisture buildup, risking electrical hazards. High temperatures may reduce airflow efficiency, leading to overheating, while strong winds can push debris into ventilation areas. Cold weather can cause condensation or ice formation, obstructing airflow. You should regularly inspect vents during adverse weather to guarantee proper ventilation and prevent safety issues.

Can Nearby Foliage Impact Exhaust Flow and Ventilation Efficiency?

Foliage interference is like a traffic jam blocking your exhaust flow, and it can seriously reduce ventilation efficiency. When leaves or branches grow too close, they become obstruction hazards that trap exhaust gases and restrict airflow. This can lead to overheating or dangerous buildup of fumes. Regularly trim back nearby foliage to keep clear pathways for exhaust, ensuring your generator runs safely and efficiently without obstruction hazards.

What Are Early Signs of Ventilation System Failure?

You’ll notice early signs of ventilation system failure through increased exhaust odors, unusual noise, or reduced airflow around the generator. If the system isn’t ventilating properly, you might see overheating or a buildup of fumes. Pay attention to these failure signs, as they indicate your ventilation system isn’t functioning correctly, which could lead to safety hazards or equipment damage. Address issues promptly to guarantee safe and efficient generator operation.

How to Identify Hidden Obstructions Blocking Exhaust Outlets?

Identifying hidden obstructions blocking exhaust outlets is like finding a needle in a haystack. You should regularly inspect outlet visibility, looking for dirt, debris, or any buildup that might hide vent obstructions. Use a flashlight to check behind or around the outlet, and consider removing covers for a thorough look. Keep an eye out for signs of poor airflow or unusual smells, which can indicate an unseen vent obstruction.

Are There Specific Regulations for Generator Clearance in Residential Areas?

Yes, there are specific regulations for generator clearance in residential areas. You need to follow local building codes and manufacturer guidelines for generator placement, guaranteeing adequate clearance requirements are met. Typically, this means maintaining a safe distance from windows, vents, and doors to prevent exhaust buildup and ensure proper ventilation. Always check your local regulations before installing your generator to ensure compliance and safety.

Conclusion

By avoiding these common mistakes, you’ll guarantee your generator runs safely and efficiently. Remember, neglecting proper ventilation or clearance can lead to dangerous carbon monoxide buildup or damage. Sometimes, a simple oversight—like blocking an exhaust or ignoring manufacturer guidelines—can cause big problems. It’s no coincidence that regular checks and correct placement safeguard your home and loved ones. Stay vigilant, follow these tips, and your generator will serve you reliably when you need it most.