To confidently understand NEC standards for standby systems, start by grasping their purpose, types, and proper design. Focus on selecting compatible power sources, correctly installing transfer switches, and guaranteeing proper grounding and bonding. Learn how to do accurate load calculations and system sizing to ensure reliability. Regular inspection, testing, and maintenance are essential to prevent common mistakes. Keep exploring these key topics to build your skills and ensure safe, compliant standby system setups.

Key Takeaways

- Understand the purpose and proper design considerations for standby systems, including battery backups and generators.

- Ensure power source compatibility, correct wiring, grounding, and bonding per NEC standards for safety and reliability.

- Select and install transfer switches based on load calculations and generator capacity, following proper wiring and testing procedures.

- Perform regular inspection, testing, and maintenance to confirm system readiness and prevent failures.

- Use additional resources and best practices to enhance system safety, compliance, and long-term performance.

Understanding the Purpose and Types of Standby Systems

Standby systems play a critical role in ensuring continuous operation during main power outages. They provide essential power through battery backup or generators, preventing interruptions in critical systems. Battery backup systems are ideal for short-term needs and quick response, offering immediate power until a generator kicks in. Generator sizing is vital; selecting the right size ensures your system can handle the load without overworking or underperforming. Small systems might only power essential devices, while larger setups support entire facilities. Understanding these types helps you choose the best solution for your needs, ensuring reliability and compliance. Proper planning and sizing are crucial to avoid downtime and meet NEC requirements, safeguarding your operations during unexpected power failures. Recognizing the importance of staying focused on proper system design and maintenance can significantly improve overall reliability and efficiency.

Key NEC Requirements for Power Source Selection and Connection

When selecting a power source for your standby system, you need to make certain it’s compatible with your load requirements and complies with NEC standards. Proper connection methods are essential to guarantee safety and reliable operation. Understanding these key NEC requirements helps you make informed choices and avoid code violations. Additionally, considering the use of organic and natural juices can promote overall health and well-being, which is beneficial when managing emergency preparedness and energy levels.

Power Source Compatibility

Ensuring compatibility between the power source and standby systems is essential for safety and compliance with NEC requirements. You must verify that your power source, whether a battery backup or generator, matches the system’s voltage, phase, and capacity. Proper generator integration involves guaranteeing the generator can handle the load and is rated for continuous operation. Battery backup systems need to be compatible with the system’s voltage and current demands to prevent overloads or failures. Using incompatible power sources can lead to system malfunctions, safety hazards, or code violations. Always consult NEC tables and manufacturer specifications for proper matching. Confirming compatibility ensures reliable operation and helps you meet safety standards while avoiding costly errors or system damage. Additionally, understanding power source compatibility is crucial for designing systems that adhere to safety standards and operate efficiently.

Proper Connection Methods

Proper connection methods are essential to guarantee that your chosen power source integrates safely and reliably with your standby system. When connecting a battery backup, ensure all wiring follows NEC guidelines for secure, grounded connections to prevent electrical faults. Use appropriate overcurrent protection devices to safeguard against overloads. Incorporate surge protection devices at the connection point to minimize damage from power surges, especially during storms or grid fluctuations. Properly sizing conductors and adhering to the correct termination practices reduce risks of overheating or faults. Always verify that connections meet NEC requirements for grounding and bonding to ensure system stability. Additionally, clear labeling of circuits helps prevent accidental disconnections or miswiring during maintenance. By following these key connection methods, you’ll enhance safety, ensure reliable operation, and protect your investment in your standby system.

Proper Transfer Switch Installation and Configuration

Choosing the right transfer switch is vital for safety and reliability, and proper wiring guarantees it functions correctly. You need to follow correct procedures during installation to prevent issues and make sure compliance with NEC standards. Regular testing and maintenance help keep your system ready and prevent unexpected failures. Incorporating stress management techniques into your routine can further enhance system reliability by reducing the risk of human errors caused by fatigue or distraction.

Selecting the Right Switch

How do you determine the right transfer switch for your standby system? First, consider your power needs, including generator maintenance and battery backup requirements. Match your system’s capacity with the switch’s load rating to guarantee reliable operation. You’ll also want a switch compatible with your generator type and size. Additionally, reviewing support hours can help ensure prompt assistance if issues arise during installation or operation.

Correct Wiring Procedures

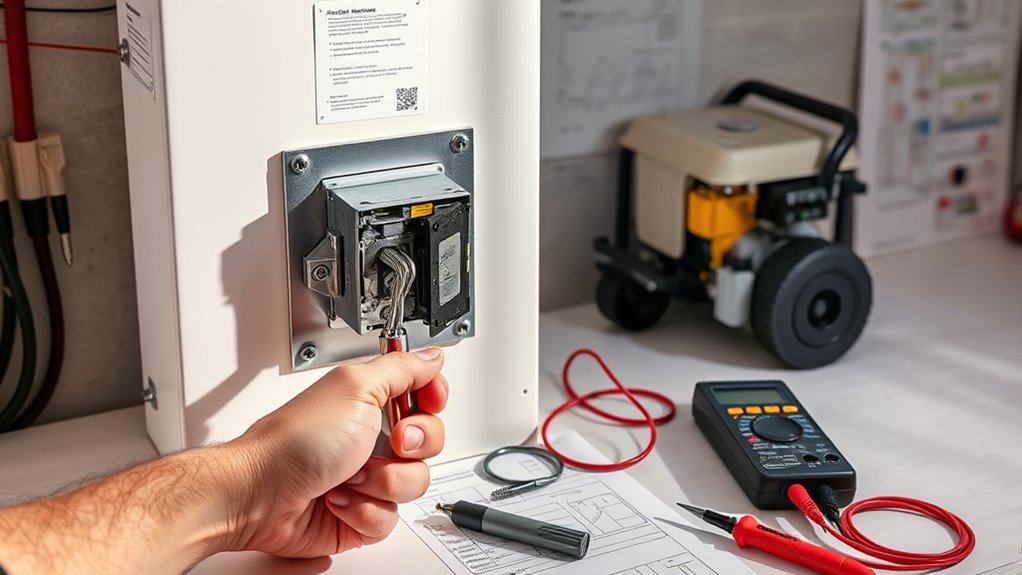

Are you confident your transfer switch is wired correctly? Proper wiring is essential for safety and reliable operation. Start by consulting detailed circuit diagrams and wiring diagrams specific to your switch model. These diagrams guide you through connecting the load, generator, and utility power sources correctly. Ensure all wiring matches the diagram, paying close attention to line and load terminals. Use the proper gauge wire and secure all connections tightly to prevent faults. Double-check that grounding is correctly established, following NEC requirements. Avoid shortcuts or improvisations; accurate wiring prevents potential hazards and system failures. Remember, a well-wired transfer switch ensures your standby system functions smoothly during an outage, providing peace of mind and safety for your home or business.

Testing & Maintenance Tips

Proper installation and configuration of your transfer switch set the stage for reliable operation during power outages. Regular testing ensures your system activates correctly, especially for critical components like battery backup and emergency lighting. Periodically simulate outages to verify the transfer switch shifts power seamlessly between utility and backup sources. Check that emergency lighting turns on without delay, and the battery backup supplies power as needed. Maintain clear documentation of testing procedures and results to identify potential issues early. Keep all connections tight and corrosion-free to prevent failures. Schedule routine inspections and perform maintenance as recommended by the manufacturer. Properly calibrated and tested transfer switches help ensure your standby system will perform effectively when you need it most, providing peace of mind during emergencies. Additionally, understanding AI vulnerabilities can help in designing smarter, more resilient backup systems that adapt to emerging threats.

Grounding and Bonding Considerations for Safety

Grounding and bonding are critical safety measures that make certain standby systems function correctly and protect personnel from electrical hazards. Proper grounding practices ensure a low-resistance path to earth, preventing shock risks during faults. Bonding techniques connect metal parts, reducing voltage differences that could cause arcing or shock. Imagine these connections like a safety web:

| Component | Purpose | Material/Method |

|---|---|---|

| Equipment Grounding | Protects equipment | Copper wire |

| System Bonding | Ensures conductive parts are linked | Bonding jumpers |

| Grounding Electrode | Dissipates fault current | Ground rod |

| Conductive Enclosure | Prevents shock hazards | Metal conduit |

Additionally, understanding the horsepower of electric dirt bikes can help in designing safer and more efficient electrical setups for off-road environments.

Conducting Load Calculations and System Sizing

To guarantee your standby system operates reliably and safely, you need to accurately conduct load calculations and size the system accordingly. Start with load estimation by identifying all essential loads, including critical equipment, lighting, and receptacles. Understand the power requirements of each load to determine the total load your system must support. Proper system sizing involves selecting a generator or UPS that can handle this calculated load comfortably, with some margin for future expansion. Remember, underestimating load can cause system failures, while overestimating leads to unnecessary costs. Use NEC guidelines to ensure your calculations align with safety standards. Load estimation is a fundamental step in designing a reliable backup power system. Accurate load estimation and appropriate system sizing are crucial to ensure your standby system provides dependable backup power when you need it most.

Inspection, Testing, and Maintenance Standards

How can you guarantee your standby systems remain reliable and compliant? Regular inspection, testing, and maintenance are essential. You need to verify your battery backup remains charged and ready, and your generator is properly sized for your load. Follow NEC standards to schedule routine checks, like inspecting connections and testing automatic transfer switches. Document all activities to ensure compliance and quick troubleshooting. Use this visual to imagine your system’s status:

| Battery Backup Check | Generator Sizing Verification |

|---|---|

| Ensure batteries are charged | Confirm generator capacity meets load |

| Test backup operation | Conduct run-time tests |

| Inspect for corrosion | Review load calculations |

| Replace aging batteries | Adjust sizing as needed |

Staying proactive prevents failures and guarantees your standby system’s performance when needed most. Additionally, maintenance procedures are vital for identifying potential issues before they lead to failure.

Common Mistakes to Avoid and Best Practices

Even experienced technicians can overlook critical details that compromise standby system reliability. One common mistake is neglecting proper generator safety procedures, which can lead to accidents or damage. Always follow manufacturer guidelines and ensure regular safety checks are in place. Another mistake is failing to establish clear emergency protocols; without them, response times slow during power outages, risking safety and equipment. Avoid ignoring routine testing and maintenance, as neglecting these tasks can cause system failures when you need them most. Keep your wiring neat and code-compliant to prevent faults. Lastly, don’t underestimate the importance of documentation—accurate records help track system health and compliance. Adopting these best practices guarantees your standby system remains dependable and ready to activate when needed.

Frequently Asked Questions

How Often Should Standby Systems Be Inspected and Tested?

You should inspect and test your standby systems at least quarterly, following recommended maintenance schedules and inspection protocols. Regular checks make certain your systems operate reliably when needed, so don’t skip these essential procedures. Conduct thorough inspections, including battery tests, system functionality, and connectivity. Keep detailed records of each inspection to track performance over time. Consistent maintenance helps prevent failures and guarantees your standby system is ready to activate instantly during emergencies.

What Are the Common Signs of Standby System Failure?

You’ll notice standby system failure signs like frequent battery degradation, which reduces backup capacity, or unpredictable power fluctuations that cause system instability. notably, studies show that over 50% of failures are linked to battery issues. If your system shows these signs, it’s time to check the batteries and connections. Addressing these problems early helps prevent unexpected shutdowns and keeps your standby system reliable when you need it most.

Can Standby Systems Be Integrated With Renewable Energy Sources?

Yes, you can integrate standby systems with renewable energy sources. By incorporating renewable integration and energy storage, you guarantee a reliable power supply even when renewable sources fluctuate. This setup allows your standby system to store excess energy generated from solar or wind, providing backup during outages or low renewable output. Proper planning and compliance with NEC guidelines are essential to achieve seamless integration and maximize your system’s efficiency.

What Certifications Are Required for Standby System Components?

You need to guarantee your standby system components meet certification standards like UL, IEC, or IEEE to guarantee safety and reliability. Component compliance is essential, so verify that batteries, inverters, and transfer switches are certified by recognized organizations. These certifications help you meet code requirements and maintain system integrity, ensuring your standby system operates effectively during outages. Always check the latest standards to stay compliant and safe.

How Does Climate Affect Standby System Installation and Maintenance?

Like a delicate dance with nature, climate considerations directly influence your standby system’s performance and longevity. Extreme temperatures, humidity, and environmental impacts demand careful installation and ongoing maintenance. In hot, humid climates, you’ll need robust cooling and corrosion protection, while cold environments call for insulation and freeze prevention. By respecting these climate influences, you guarantee your standby system remains reliable, resilient, and ready to serve when needed most.

Conclusion

By understanding the purpose, selecting the right type, installing correctly, grounding safely, calculating loads accurately, and maintaining diligently, you guarantee your standby system operates reliably. Avoid common mistakes, follow standards, and stay informed—all to protect your property and peace of mind. Master these essentials, and you’ll confidently manage your standby system, from initial setup to ongoing operation, turning uncertainty into assurance and vulnerability into resilience.