Common installation mistakes include skipping detailed site assessments, not following manufacturer guidelines, using incorrect tools, and neglecting safety precautions. Poorly aligned hardware and improper wiring can lead to system failures and hazards. Failing to test and check quality early can cause ongoing problems. To guarantee a successful setup, you need proper planning, precise techniques, and safety measures. Stay with us to discover how avoiding these mistakes can save you time and costs.

Key Takeaways

- Skipping detailed site surveys can cause unforeseen obstacles and compliance issues during installation.

- Using incorrect tools or poor alignment techniques leads to system failure and safety hazards.

- Neglecting safety precautions and proper wiring practices increases the risk of injuries and electrical faults.

- Failing to conduct thorough testing and quality checks can result in undetected faults and safety concerns.

- Not following manufacturer guidelines and best practices compromises system performance, safety, and durability.

Improper Planning and Site Assessment

Have you thoroughly assessed your site before starting the installation? Conducting a detailed site survey is essential to identify potential challenges and guarantee proper resource allocation. Skipping this step can lead to unexpected obstacles, delays, and increased costs. During your site survey, examine factors like terrain, access points, electrical availability, and structural stability. Proper planning allows you to allocate resources efficiently, avoiding shortages or misplacement of materials and labor. It also helps you anticipate any modifications needed to meet safety standards or code requirements. By investing time in a extensive site assessment, you set a solid foundation for a smooth installation process, reducing mistakes caused by overlooked details and ensuring your project proceeds on schedule and within budget. Recognizing the artistic significance of the project can also inspire more thoughtful planning and creative problem-solving.

Skipping Manufacturer Guidelines

Failing to follow manufacturer guidelines can undermine the entire installation process. Ignoring manufacturer instructions often leads to improper setup, reduced product lifespan, or safety hazards. To prevent these issues, you should:

Ignoring manufacturer guidelines risks safety, durability, and proper function of your installation. Always follow instructions carefully.

- Read all installation guidelines thoroughly before starting.

- Follow recommended steps precisely, avoiding shortcuts.

- Use only the specified tools and parts as outlined in the instructions.

- Remember that proper preparation is essential for a smooth and successful installation.

Skipping or neglecting manufacturer instructions can cause costly mistakes and void warranties. Manufacturers design their installation guidelines to ensure safety, efficiency, and durability. By adhering to these instructions, you minimize risks and increase the likelihood of a successful installation. Always prioritize the manufacturer’s recommended procedures to ensure your project’s integrity and longevity. Remember, the manufacturer’s instructions are there for your safety and the best performance of your product.

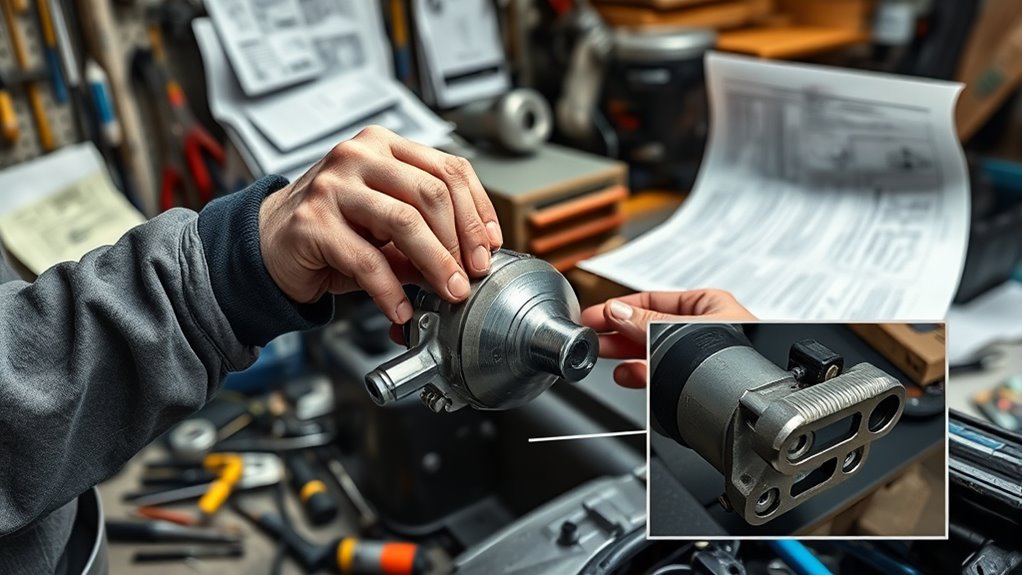

Incorrect Tool and Equipment Usage

Using the wrong tools or equipment during installation can compromise the entire process, leading to damage, safety hazards, or a faulty setup. Power tools are often essential, but choosing the incorrect type or using them improperly can cause material damage or personal injury. Similarly, relying on inaccurate measurement devices can result in misaligned components or structural issues. Always verify that your power tools are suitable for the task and in good condition before starting. Use precise measurement devices like levels, rulers, or laser guides to ensure everything is positioned correctly. Avoid improvising with makeshift tools, as they can lead to mistakes. Proper tool selection and correct usage are key to a safe, efficient, and reliable installation. Investing in quality tools and understanding their proper application prevents costly errors. Additionally, understanding Kia Tuning options can help you select the right upgrades and avoid improper modifications that could damage your vehicle.

Overlooking Safety Precautions

You might think safety precautions are optional, but skipping safety gear puts you at unnecessary risk. Ignoring warning signs can lead to accidents that could have been avoided. Always prioritize safety to protect yourself and ensure the job gets done right. Incorporating proper safety measures is especially important in workplace safety to prevent injuries and maintain a productive environment.

Skipping Safety Gear

Have you ever considered how skipping safety gear can lead to serious injuries during installation? Neglecting personal protective equipment (PPE) puts you at risk. To stay safe, follow these safety protocols:

- Always wear a helmet to protect your head from falling objects.

- Use gloves to prevent cuts and improve grip.

- Wear eye protection to shield your eyes from debris and sparks.

- Additionally, understanding electric dirt bike safety features can further reduce risks during maintenance.

Skipping safety gear might seem like a time-saver, but it compromises your safety. PPE is designed to minimize injuries, and ignoring it can lead to costly setbacks or permanent damage. Remember, safety protocols aren’t optional—they’re essential for a secure work environment. By prioritizing proper safety gear, you reduce the risk of accidents and ensure a smoother, more efficient installation process.

Ignoring Warning Signs

Could ignoring warning signs during installation lead to serious accidents? Absolutely. When you overlook warning signs, you risk damaging equipment or causing injury. Ignoring warning signs, like unusual vibrations, strange noises, or overheating, indicates something’s wrong. Instead of dismissing these cues, investigate and address them promptly. Neglecting maintenance or warning signals can lead to system failures or safety hazards. Always stay alert to any signs of trouble and don’t assume they’ll resolve on their own. By paying attention to warning signs and acting quickly, you prevent bigger issues later. Remember, safety isn’t just about following procedures; it’s also about listening to your equipment and responding to its warnings. Proper maintenance is essential for ensuring long-term safety and reliability. Ignoring warning signs puts everyone at risk and can cause costly damage.

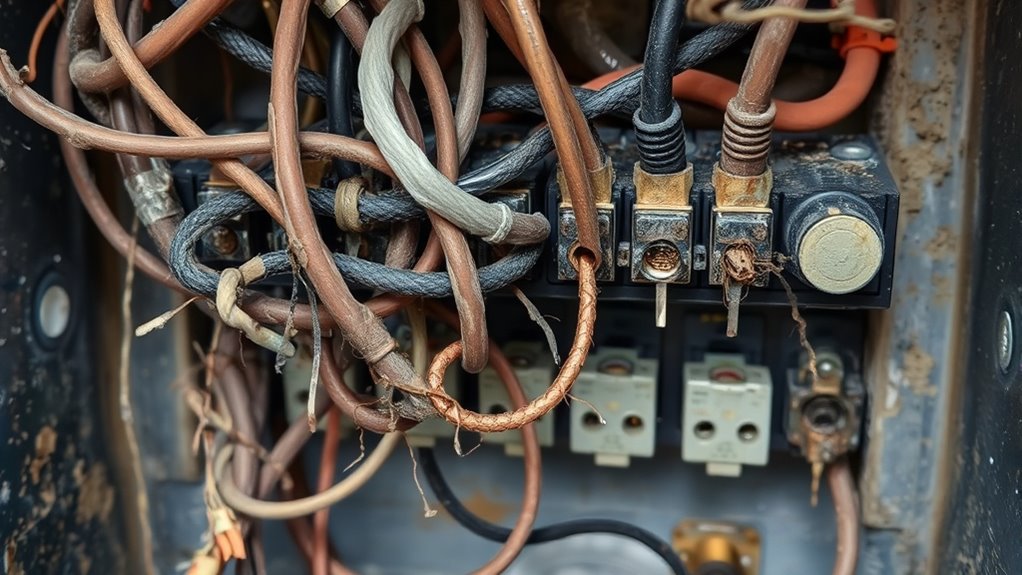

Inadequate Wiring and Connection Practices

Inadequate wiring and connection practices can lead to serious issues. You might use incorrect wiring configurations, poor connection techniques, or skip essential safety measures. These mistakes can compromise system performance and safety, so it’s vital to follow proper procedures. Additionally, neglecting to use appropriate accessories like strainers and spray tips can result in uneven finishes and equipment damage.

Incorrect Wiring Configurations

Incorrect wiring configurations are a common cause of electrical problems and safety hazards. Poorly planned circuit design or misinterpreted wiring diagrams can lead to issues like short circuits, overloads, or fire risks. To avoid these mistakes, you should:

- Follow wiring diagrams precisely, ensuring all connections match the schematic.

- Confirm that circuit design accommodates load requirements and safety standards.

- Use proper wire gauges and secure connections to prevent loose or faulty contacts.

- Regularly inspect the wiring setup to identify potential issues early and maintain electrical safety.

Always double-check your wiring against the diagrams and ensure your setup aligns with the intended circuit design. Making assumptions or rushing through connections can result in dangerous faults. Correct wiring configurations are essential for safety, efficiency, and long-term reliability of your electrical system.

Poor Connection Techniques

Have you ever experienced a circuit failure or intermittent power issues? Poor connection techniques often cause these problems by compromising connection stability. If you don’t secure connections properly, wires can loosen over time, leading to electrical failures. Inadequate cable management also contributes to instability, as tangled or poorly organized cables increase stress on connections and make troubleshooting difficult. To ensure a reliable setup, always strip wires correctly and tighten terminals securely. Avoid twisting wires excessively or leaving loose ends. Use appropriate connectors and cable ties to keep cables neat and stable. Proper cable management not only improves connection stability but also reduces wear and tear. Additionally, following Hyundai Tuning best practices can help optimize overall system performance. Taking the time to make solid, well-organized connections prevents future issues and keeps your system running smoothly.

Inadequate Safety Measures

Failing to follow proper wiring and connection practices can pose serious safety risks, including electrical shocks and fires. To prevent this, guarantee you implement adequate safety measures:

- Install protective barriers around exposed wiring to prevent accidental contact.

- Keep emergency exits clear of wiring or equipment that could block escape routes.

- Regularly inspect connections for loose or damaged wiring, and fix issues immediately.

- Utilize expert voice actors to communicate safety instructions clearly and effectively in training or warning materials.

Poor Alignment and Mounting Techniques

Poor alignment and mounting techniques can considerably compromise the safety and functionality of your installation. If you neglect proper alignment, you risk creating alignment issues that can cause uneven wear, vibrations, or system failure. Mounting faults, such as using incorrect hardware or insufficient support, can lead to instability, increased stress on components, or even complete detachment. To prevent these problems, double-check measurements and guarantee all parts are aligned precisely before fastening. Use the right tools and hardware for your specific setup. Rushing through mounting tasks or ignoring manufacturer guidelines increases the likelihood of faults. Remember, proper alignment and secure mounting are essential for peak performance, safety, and longevity of your installation. Taking these steps helps avoid costly repairs or potential hazards later on.

Neglecting Testing and Quality Checks

Neglecting testing and quality checks can lead to overlooked issues that compromise the safety and performance of your installation. Skipping proper inspection protocols increases the risk of undetected faults. To avoid this, guarantee you follow these steps:

Neglecting testing risks overlooked faults that threaten safety and performance.

- Conduct thorough inspections based on established protocols to identify potential problems early.

- Document all findings carefully, adhering to documentation procedures for future reference and accountability.

- Perform functional testing to verify that all components operate correctly and meet safety standards.

Implementing strict inspection protocols and maintaining detailed documentation procedures help catch issues before they escalate. Regular testing confirms the integrity of your installation, ensuring it’s safe, reliable, and compliant with regulations. Don’t underestimate the importance of these checks—they’re essential for long-term success.

Frequently Asked Questions

How Can I Prevent Common Installation Errors Effectively?

To prevent common installation errors, you should follow a thorough installation checklist and seek professional guidance when needed. Carefully review each step before starting, double-check connections, and verify all tools are appropriate. Consulting experts can help you identify potential pitfalls early. Taking these precautions minimizes mistakes, saves time, and guarantees a successful installation. Remember, thorough preparation and professional advice are your best defenses against costly errors.

What Are the Signs of an Improperly Installed System?

Like a vintage radio left unplugged, an improperly installed system shows clear setup indicators. You might notice inconsistent performance, strange noises, or frequent shutdowns—classic installation pitfalls. Loose connections, misaligned components, or error messages also signal issues. If your system isn’t running smoothly or you’re experiencing unexpected errors, it’s a sign to double-check your setup. Catching these signs early helps avoid costly repairs and guarantees your system functions flawlessly.

Are There Recommended Resources for Troubleshooting Installation Issues?

You should start with the installation guides provided by the manufacturer, as they offer step-by-step instructions to help you troubleshoot issues. Additionally, use troubleshooting tools like diagnostic software or online resources to identify and resolve problems quickly. Don’t hesitate to reach out to customer support if needed, as they can offer expert advice. Combining these resources guarantees a smoother installation process and helps you address any issues effectively.

How Often Should I Perform Maintenance After Installation?

You should perform maintenance every 6 to 12 months, depending on your equipment and usage. Studies show that regular inspections can reduce breakdowns by up to 30%. Follow a maintenance schedule that matches your system’s needs, ensuring timely inspections and servicing. This proactive approach keeps everything running smoothly, extends equipment lifespan, and minimizes costly repairs. Stick to your inspection frequency to stay ahead of potential issues and maximize efficiency.

What Are the Legal Requirements for Installation in My Area?

You need to check your local permits and licensing requirements before starting installation. Many areas require specific permits for electrical, plumbing, or construction work, and failure to obtain them can lead to fines or project delays. Contact your city or county building department to confirm the necessary permits and licenses. Ensuring compliance helps you avoid legal issues and guarantees your installation meets all safety standards and regulations.

Conclusion

By avoiding these common mistakes, you’ll find that installation becomes smoother and safer. Sometimes, a simple oversight or skipping a guideline can lead to unexpected issues down the line. Remember, taking the time to plan, follow instructions, and double-check your work isn’t just good practice—it’s the key to a successful project. So, the next time you install, trust that paying attention to details might just save you from surprises you never saw coming.