To avoid common advanced installation mistakes, start with thorough planning and site assessment to prevent costly errors. Follow manufacturer guidelines closely for safety and system longevity. Make precise measurements, calibrate properly, and guarantee wiring is secure and correctly organized. Don’t skip safety protocols or thorough testing, which can cause failures or hazards. Finally, consider future upgrades and maintenance early on. Continue exploring these essential steps to ensure a smooth, reliable setup.

Key Takeaways

- Conduct thorough site assessments to identify environmental factors and existing infrastructure before installation.

- Follow manufacturer guidelines precisely for tools, procedures, and safety measures during setup.

- Ensure accurate measurements, calibration, and secure wiring to prevent malfunctions and safety hazards.

- Incorporate maintenance, upgrade, and future-proofing strategies into initial planning for long-term performance.

- Prioritize safety protocols and use proper PPE to prevent accidents and ensure a secure installation environment.

Neglecting Proper Planning and Site Assessment

Neglecting proper planning and site assessment can lead to costly mistakes and project delays. Before starting installation, you need to conduct a thorough site evaluation to identify potential issues. Environmental factors such as soil stability, drainage, and exposure to weather play a critical role in your project’s success. Overlooking these factors can cause structural problems, safety hazards, or system failures down the line. Make sure you assess the site meticulously, considering existing infrastructure and natural conditions. Failing to do so can result in unforeseen complications that require costly fixes or redesigns. Taking the time to evaluate environmental factors and plan accordingly ensures your installation proceeds smoothly, on time, and within budget, avoiding unnecessary setbacks that could have been prevented with proper preparation. Additionally, understanding soil stability and its impact on foundation integrity is essential for long-term success.

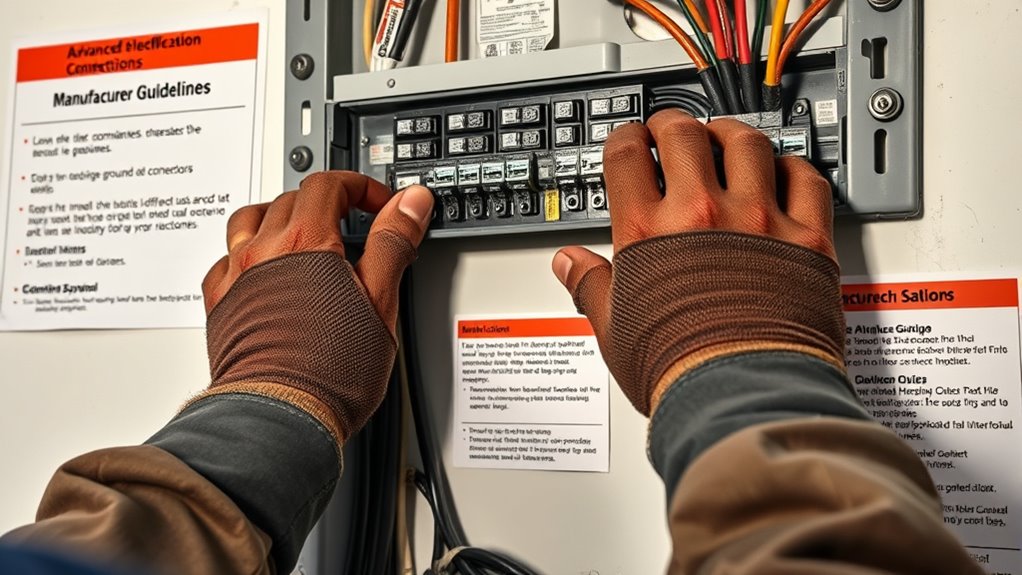

Overlooking Manufacturer Guidelines and Specifications

Failing to follow manufacturer guidelines and specifications can compromise the safety and longevity of your installation. Ignoring these directives risks improper setup, voiding warranties, and causing costly damage. To guarantee proper specification compliance, pay attention to:

Neglecting manufacturer guidelines endangers safety, warranty, and long-term performance.

- Correct installation procedures outlined by the manufacturer

- Recommended tools and materials

- Specific safety measures and warnings

- Environmental conditions suitable for operation

- Load capacities and spacing requirements

- Adhering to refrigeration cycle principles ensures optimal performance and efficiency.

Skipping Precise Measurements and Calibration

Skipping precise measurements and calibration can lead to misaligned components, reducing the system’s efficiency and safety. When you neglect measurement accuracy, your installation risks errors that may cause malfunctions or safety hazards. Proper calibration techniques ensure that all parts operate within specified tolerances, maintaining system performance. Without accurate measurements, you might install components at incorrect angles or distances, leading to vibrations, wear, or failure. Always double-check measurements before proceeding, and use reliable calibration tools to verify settings. Consistent calibration ensures your system functions at its best and lasts longer. Ignoring this step can result in costly rework and compromised safety. Take the time to perform precise measurements and apply correct calibration techniques; it’s essential for a successful, reliable installation. Additionally, understanding the importance of water safety measures can help prevent accidents and ensure a secure environment.

Ignoring Safety Protocols and Protective Measures

While focusing on installation details is important, overlooking safety protocols and protective measures can lead to serious accidents. Failing to prioritize personal protective equipment (PPE) and emergency preparedness increases risks markedly. Always ensure you wear appropriate PPE, such as gloves, goggles, and helmets, to protect yourself from hazards. Neglecting safety procedures can result in electrical shocks, falls, or equipment damage. To stay safe, consider these essentials:

- Regular safety training sessions

- Clear emergency escape routes

- Proper handling of tools and materials

- Rigorous site inspections

- Immediate access to first aid kits

- Recognizing the importance of safety protocols in preventing accidents

Ignoring these measures compromises your safety and project integrity. Always remember, safety should never be an afterthought during advanced installations. Prioritize protective measures to prevent accidents and ensure a smooth, secure process.

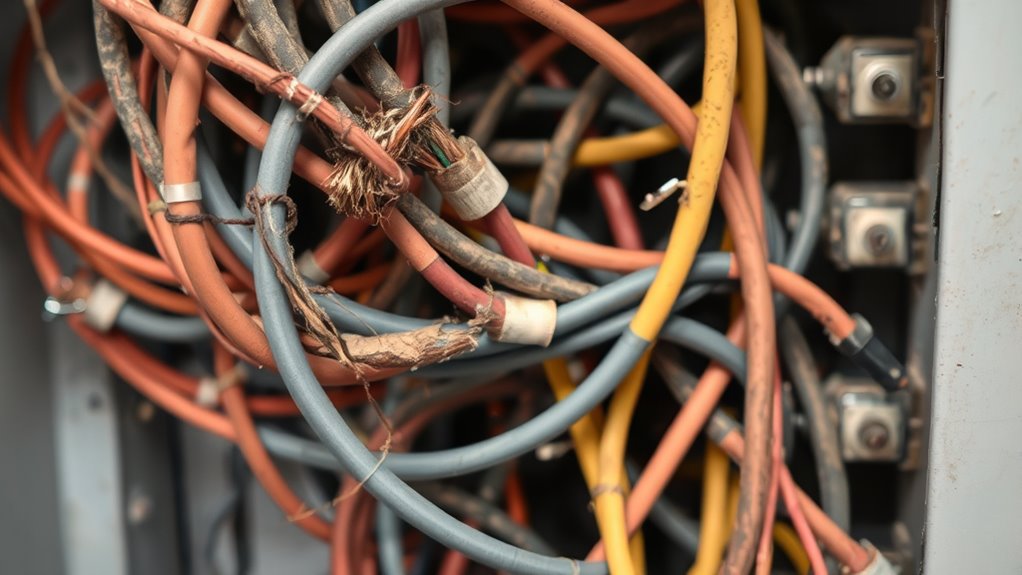

Inadequate Wiring and Connection Practices

Poor wiring techniques and loose connections can lead to failures and safety hazards. You need to guarantee every wire is properly installed and securely connected. Skipping these steps can cause serious problems down the line. Additionally, ensuring proper connection support systems can prevent accidental disconnections and maintain system integrity.

Proper Wiring Techniques

Proper wiring techniques are essential for ensuring safety and reliability in any installation. To achieve this, pay close attention to cable selection, ensuring wires can handle the load and environment. Always follow the wiring diagram precisely to prevent errors. Proper techniques include securing connections tightly, avoiding unnecessary twists, and maintaining organized wiring paths. Be mindful of avoiding loose or exposed wires that could cause shorts or shocks. Use proper insulation and connectors to enhance safety and longevity. Additionally, incorporating essential oils for electrical safety can promote a safer working environment by reducing stress and enhancing focus during installation.

Secure Connection Practices

Secure connection practices build on proper wiring techniques by ensuring that every contact point maintains electrical integrity. You need to implement strong encryption protocols to protect data transmitted across your network, preventing unauthorized access. Regularly updating and managing certificates is vital to maintain secure connections and avoid vulnerabilities. When making connections, double-check that all wires are securely fastened and insulated properly, reducing the risk of short circuits or data breaches. Use trusted hardware and follow manufacturer guidelines for connection standards. Avoid shortcuts like reusing old cables or neglecting proper grounding, as these can compromise security. Consistent certificate management helps verify identities and guarantee encryption remains effective. Additionally, proper installation techniques ensure that all hardware components are correctly assembled, further strengthening your system’s security. By paying attention to these details, you strengthen your system’s defense against potential security breaches caused by inadequate wiring and connection practices.

Failing to Test and Troubleshoot Thoroughly

Neglecting to thoroughly test and troubleshoot your installation can lead to overlooked issues that may cause failures or safety hazards down the line. You need to verify everything works correctly before finalizing. This includes checking sensor calibration to ensure accuracy, confirming all connections are secure, and testing the system’s response under various conditions. Don’t forget to install the latest software updates, which can fix bugs and improve performance. Troubleshooting involves identifying problems quickly and resolving them efficiently. Failing to do so can result in costly downtime or unsafe operations. Remember, an exhaustive test reduces future troubleshooting needs and ensures reliability. Additionally, understanding privacy policies can help you stay compliant with data regulations during system testing.

Underestimating Maintenance and Future Upgrades

Failing to account for ongoing maintenance and future upgrades can leave your system vulnerable to unexpected breakdowns and costly repairs. When planning your installation, consider future proofing considerations, such as scalability and compatibility with new technology. This proactive approach can help prevent issues related to outdated components or incompatible systems. Maintenance scheduling can result in overlooked issues that worsen, leading to more extensive repairs. Regular upkeep minimizes downtime and extends equipment lifespan. Don’t underestimate how future upgrades might require additional space or power capacity; planning ahead saves headache and money down the line. By integrating maintenance and upgrade strategies into your initial design, you create a resilient system that adapts seamlessly to evolving needs, reducing long-term costs and ensuring consistent performance.

Frequently Asked Questions

How Do I Prioritize Installation Steps for Complex Systems?

You should start by evaluating the installation sequencing to determine the logical order of tasks. Prioritize critical tasks that impact subsequent steps, ensuring foundational elements are in place first. Break down complex systems into manageable tasks and assign deadlines accordingly. Use task prioritization techniques like the Eisenhower matrix to identify urgent versus important steps. This approach keeps your installation organized, minimizes errors, and ensures smoother progress throughout the project.

What Are Common Signs of Improper Calibration in Installations?

You’ll notice calibration issues when systems don’t perform as expected, like inconsistent readings or erratic operation. Misalignment problems often cause inaccurate outputs or mechanical stress. If you see these signs, double-check calibration settings and alignment procedures. Regular testing and adjustments help catch these issues early, preventing costly errors. Address calibration issues promptly to guarantee your installation functions smoothly and maintains peak accuracy.

How Often Should Advanced Installations Be Inspected or Maintained?

You should inspect your advanced installation at least every six months and follow a regular maintenance schedule to guarantee peak performance. Regular inspections help catch issues early, preventing costly repairs and downtime. Depending on your system’s usage and environment, more frequent checks might be necessary. Staying consistent with your inspection frequency and adhering to a proper maintenance schedule keeps your system running smoothly and extends its lifespan.

What Tools Are Essential for Ensuring Safe Wiring Practices?

You need essential tools like insulated screwdrivers, wire strippers, and a multimeter for safe wiring practices. Always refer to circuit diagrams to guarantee correct connections, and make sure your tools are properly calibrated before starting. Using calibrated tools helps prevent errors and ensures safety. Regularly inspecting your tools and verifying their calibration maintains accuracy and reduces the risk of electrical hazards during advanced installations.

How Can I Update Systems Safely for Future Upgrades?

Think of updating your systems as planting seeds for future growth. To do it safely, regularly check for software updates to patch vulnerabilities and improve performance. Make certain hardware compatibility before upgrading to prevent conflicts, and back up your data to safeguard against setbacks. Follow manufacturer instructions carefully, and test everything in a controlled environment first. This approach helps your system flourish and stay resilient for future upgrades.

Conclusion

By avoiding these common installation mistakes, you not only guarantee your setup functions smoothly, but you also stumble upon the importance of thorough planning and safety. Sometimes, the tiniest oversight can lead to unexpected issues down the line, reminding you that attention to detail truly makes all the difference. When you take the time to do it right, you create a reliable system—one that’s ready to support your needs, now and in the future.