If you’re troubleshooting your generator’s battery chargers and keep-alive systems, start by checking for signs like frequent dead batteries, corrosion, or inconsistent voltage readings. Confirm connections are tight and clean, test the system with a multimeter, and look for any physical damage or corrosion on terminals. Reset the system if needed, and perform regular maintenance. For ongoing issues, understanding common causes and when to seek professional help guarantees reliable operation—more helpful tips follow.

Key Takeaways

- Regularly inspect and clean battery terminals to prevent corrosion and ensure proper conductivity.

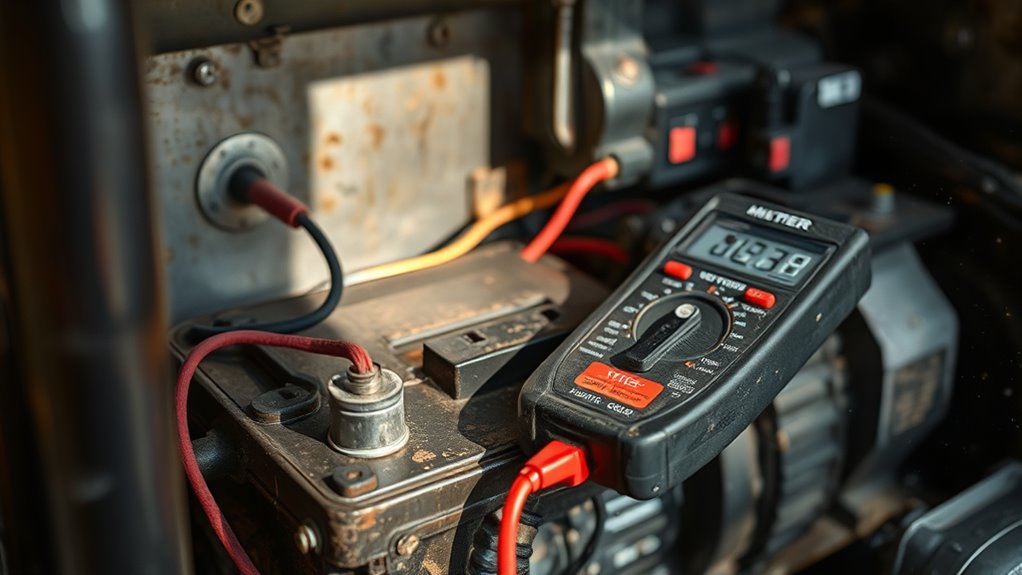

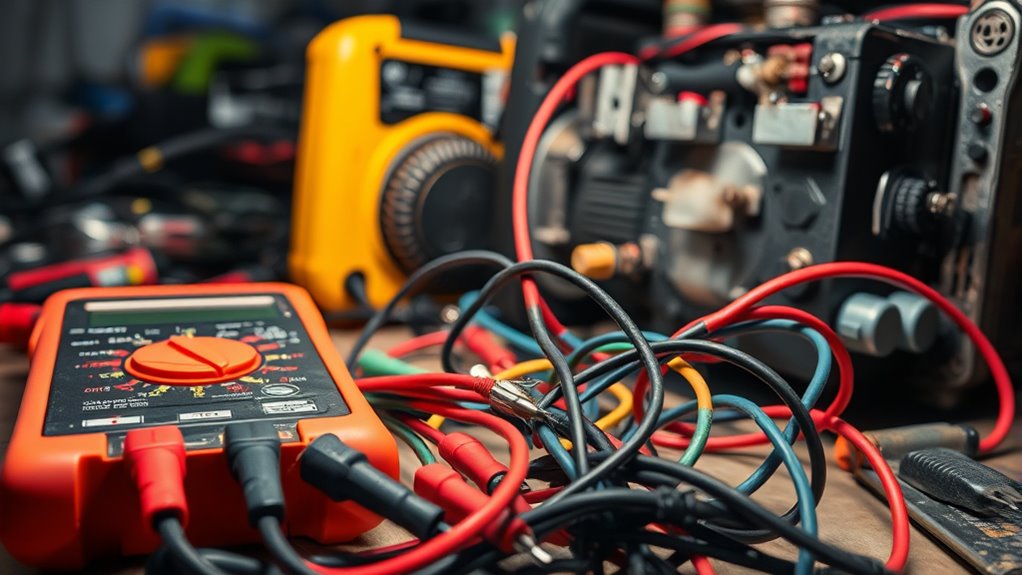

- Use a multimeter to check voltage consistency and identify irregular fluctuations or dead batteries.

- Confirm that charger connections are secure, properly fitted, and free from damage or corrosion.

- Reset the keep-alive system following manufacturer instructions if errors persist or voltage issues occur.

- Seek professional diagnosis if troubleshooting does not resolve battery or system faults.

What Are the Signs of a Failing Battery Charger in a Generator?

A failing battery charger in a generator often shows itself through several clear signs. You might notice that the battery’s lifespan shortens unexpectedly, requiring frequent replacements. This indicates the charger isn’t maintaining proper charge levels. Additionally, if you experience difficulty with charger compatibility—such as the charger not fitting properly or not recognizing the battery—it could signal a problem. A malfunctioning charger may also produce unusual noises or heat, pointing to internal issues. Over time, these signs can lead to battery failure or reduced performance. If you observe any of these symptoms, it’s a sign that the charger may be failing and needs inspection or replacement. Addressing these signs early helps preserve your battery and ensures reliable generator operation. Automation technologies in related industries highlight the importance of regular maintenance and early detection of faults to prevent costly downtime.

How Can I Test if My Keep-Alive System Is Working Properly?

To guarantee your Keep-Alive system is functioning correctly, start by checking its power source. Measure the battery voltage with a multimeter; a healthy system usually maintains a voltage close to the battery’s resting level. If the voltage drops considerably when the system is active, it may indicate a problem. Next, perform system diagnostics by observing if the Keep-Alive circuit consistently supplies power during generator shutdowns. You can also test by disconnecting the main battery and monitoring whether the system preserves essential settings or maintains charge. If the battery voltage remains stable and diagnostics show continuous power delivery, your Keep-Alive system is working properly. If not, further inspection or repairs might be necessary to ensure reliability. Regularly checking battery health and maintaining proper hydration can also support optimal system performance.

What Are Common Causes of Battery Charging Issues?

Charging issues often stem from faulty connections, worn-out components, or insufficient power sources. You might notice battery corrosion on terminals, which hampers conductivity. Voltage fluctuations can also prevent proper charging, causing inconsistent power delivery. Loose or damaged cables are common culprits, disrupting the flow of current. Additionally, a failing alternator or charger can’t supply steady voltage, leading to undercharging or overcharging. To visualize these causes, consider the table below:

| Issue | Symptom | Solution |

|---|---|---|

| Battery corrosion | Poor connection, slow charge | Clean terminals, inspect cables |

| Voltage fluctuations | Inconsistent power output | Check power source, replace faulty components |

| Loose connections | Intermittent charging | Tighten or replace cables |

| Worn-out charger | Inadequate charging | Replace charger |

| Damaged battery | Reduced capacity | Replace battery |

Regularly inspecting your security systems can help prevent some of these issues, ensuring your generator remains reliable when needed.

How Do I Reset or Reboot My Generator’s Battery Management System?

To reset your generator’s battery management system, start by locating the reset button—usually found on the control panel. If that doesn’t work, you can try disconnecting the power, waiting a few moments, then reconnecting it. This simple process can often resolve issues and restore proper battery function. Ensuring your workspace is organized and clutter-free can also improve overall troubleshooting efficiency.

Accessing the Reset Button

Wondering how to reset your generator’s battery management system? First, locate the battery access panel, which is usually near the engine or control panel. Once you have access, look for the reset button—often a small, recessed switch. You might need a screwdriver or a paperclip to press it. Follow the reset procedures outlined in your generator’s manual, which typically involve holding the button for a few seconds. Be cautious not to force or damage any components. Resetting the system can clear faults or errors, restoring proper operation. Make certain the generator is off before accessing the reset button, and always double-check your manual for specific instructions. Proper battery access and system reset procedures help maintain your generator’s performance and longevity.

Disconnecting and Reconnecting Power

After resetting the system using the reset button, you may need to fully reboot your generator’s battery management system to resolve persistent issues. Start by disconnecting the battery cables carefully to ensure battery safety, preventing any accidental short circuits or sparks. Be cautious of potential power surges when reconnecting, as sudden spikes can damage the system. Wait a few minutes before reconnecting the cables, allowing residual energy to dissipate. When reconnecting, do so firmly and in the correct order to avoid unnecessary strain on components. Once reconnected, turn on your generator and check if the system resets properly. This process helps clear glitches and guarantees your battery management system functions smoothly, safeguarding against future power surges or faults. Proper handling of battery cables is essential for safe and effective resetting.

What Maintenance Steps Can Prevent Keep-Alive and Charging Problems?

Regularly inspect your battery for corrosion, loose connections, and signs of wear to keep it in top shape. Make sure all connections are tight and free of dirt or debris, which can disrupt charging. Taking these simple steps helps prevent keep-alive and charging issues before they become major problems. Additionally, understanding AI in Business can help optimize maintenance schedules through predictive analytics, reducing downtime and increasing efficiency.

Regular Battery Inspections

How can you prevent keep-alive and charging issues in your generator’s battery system? Regular battery inspections are key. Check for signs of battery corrosion, which can hinder electrical flow, and clean terminals as needed. Ensure your battery undergoes proper charging cycles; incomplete or excessive cycles can reduce battery lifespan. Consistently monitor voltage levels and electrolyte strength if applicable. Keep an eye on physical damage or leaks that might point to internal issues. Use a table to track maintenance tasks and results:

| Task | Frequency | Notes |

|---|---|---|

| Inspect terminals | Monthly | Look for corrosion and clean |

| Test voltage | Monthly | Ensure proper charging voltage |

| Check electrolyte | Quarterly | Maintain correct fluid levels |

| Clean battery | When needed | Remove corrosion buildup |

| Examine for damage | Regularly | Replace if necessary |

Additionally, performing periodic battery capacity tests can help identify potential problems before they cause failure.

Proper Connection Maintenance

Maintaining proper connections in your generator’s battery system is vital to prevent keep-alive and charging issues. Regularly check for battery corrosion, which can weaken connection integrity and disrupt electrical flow. Clean terminals with a wire brush or a mixture of baking soda and water to remove any buildup. Make certain that all terminals and connectors are tight and secure, as loose connections can cause charging problems and reduce battery lifespan. Protect connections from moisture and dirt by applying dielectric grease, which also helps prevent corrosion. Additionally, ensuring proper battery maintenance can extend the overall life of your battery and improve system reliability. Consistently inspecting and maintaining connection integrity keeps your system reliable, guaranteeing that the battery charges properly and stays operational when needed. Proper connection maintenance is a simple yet essential step to avoiding keep-alive failures and prolonging your generator’s battery life.

How Do I Identify Faulty Wiring or Connections Affecting Battery Charging?

Faulty wiring or loose connections can disrupt the flow of electricity, preventing your generator’s battery charger from working properly. To identify these issues, start by inspecting wiring diagrams to understand the correct wiring layout. Look for signs of connection corrosion, such as rust, discoloration, or buildup around terminals and connectors. Loose or frayed wires are common culprits and should be secured or replaced. Use a multimeter to check continuity; if there’s no reading, the wire or connection may be broken. Also, ensure that all connectors are tightly secured and free from corrosion. Regularly inspecting and cleaning terminals helps prevent issues, guaranteeing the wiring remains intact and your battery charges efficiently. Additionally, paying attention to portable camping equipment power sources can help identify potential wiring issues that affect charging performance.

When Should I Call a Professional for Generator Battery or Keep-Alive Troubles?

Knowing when to call a professional is essential, especially if troubleshooting steps haven’t resolved your generator’s battery or keep-alive issues. If you’ve already tried basic checks like cleaning terminals or inspecting connections, it’s time to seek expert help. Signs include persistent low voltage readings, difficulty starting, or a dead battery despite charging. Professionals can perform accurate voltage testing and determine if a battery replacement is necessary.

| Issue | When to Call a Professional | Recommended Action |

|---|---|---|

| Battery won’t hold charge | Voltage testing shows irregular results | Professional assessment and replacement |

| Dead battery after charging | Troubleshooting fails to fix issue | Battery replacement recommended |

| Consistent low voltage | Unable to stabilize voltage levels | Call for expert diagnosis |

| Frequent starting problems | Basic fixes don’t work | Professional inspection needed |

| Keep-alive system failure | Persistent errors persist | Expert repair or replacement |

Frequently Asked Questions

Can Extreme Temperatures Impact My Generator’s Battery Charging Performance?

Extreme temperatures can considerably impact your generator’s battery charging performance. Cold weather reduces chemical reactions inside the battery, decreasing charging efficiency and making it harder to start your generator. Conversely, high temperatures can cause the battery to overheat, leading to faster degradation and reduced lifespan. To maintain ideal charging efficiency, keep your generator in a temperature-controlled environment and check battery health regularly, especially during extreme weather conditions.

How Do I Differentiate Between Battery Charger Failure and Battery Deterioration?

Did you know that over 50% of generator issues are caused by battery problems? To differentiate between battery charger failure and deterioration, check the battery health first—use a voltmeter to measure voltage. If the voltage is low despite the charger indicators showing proper operation, your battery may be deteriorated. Conversely, if the charger indicators show faults or no power, the charger itself might be failing.

What Safety Precautions Should I Take When Inspecting Generator Wiring?

When inspecting generator wiring, prioritize electrical safety by disconnecting the power before starting. Use an inspection checklist to identify loose connections, damaged wires, or corrosion. Wear insulated gloves and safety goggles to protect yourself from sparks or electrical shocks. Keep tools insulated and avoid working in wet conditions. Always double-check that the generator is off and properly grounded to prevent accidents during your inspection.

Are There Specific Brands or Models More Reliable for Battery Keep-Alive Systems?

Think of choosing a reliable battery keep-alive system like selecting a trusted compass for a journey—you need clarity and precision. Some brands, like Xantrex and Victron, have strong reputations for durability and consistent performance. When considering models, confirm compatibility with your generator to avoid mismatches. Based on user reviews, these brands often deliver dependable operation, helping you keep your generator ready when you need it most.

How Often Should I Schedule Professional Diagnostics for My Generator’s Electrical System?

You should schedule professional diagnostics for your generator’s electrical system at least once a year or every 200-300 hours of operation, whichever comes first. Following a regular maintenance schedule helps catch issues early and keeps your generator running smoothly. Adjust diagnostic intervals based on usage, environmental conditions, and manufacturer recommendations. Consistent inspections guarantee your battery keep-alive system and electrical components stay reliable, preventing unexpected failures and extending your generator’s lifespan.

Conclusion

If your generator’s battery charger or keep-alive system isn’t working, don’t ignore it. For example, a business relying on backup power faced unexpected downtime because a loose connection went unnoticed. Regular checks and maintenance can prevent such issues. If troubleshooting doesn’t fix the problem, calling a professional ensures safety and proper repair. Staying proactive keeps your generator reliable when you need it most, saving you time and costly repairs down the line.