To comply with service disconnect requirements, you need to follow NEC standards on placement, accessibility, and sizing. This means installing switches where they’re easy to reach, properly rated for your load, and correctly grounded. Distinguish between main and local disconnects to ensure safety and code adherence, especially in residential versus commercial setups. Regular inspections, proper labeling, and documentation are key to avoiding costly mistakes. Keep learning to master all critical safety and compliance details.

Key Takeaways

- Proper placement and accessibility of disconnects ensure quick, safe power shutoff during emergencies or maintenance.

- Accurate sizing and grounding of disconnect devices are essential to meet NEC standards and prevent overloads.

- Regular maintenance, inspections, and proper labeling help maintain compliance and system safety.

- Main vs. local disconnects serve different purposes; understanding their roles ensures proper installation and code adherence.

- Documentation and permits are critical for compliance, safety, and successful inspections throughout the system’s lifecycle.

Understanding the Role of Service Disconnects in Electrical Safety

Have you ever wondered how electrical safety is maintained in your home or business? Service disconnects play a essential role by providing a safe way to cut off power quickly during emergencies or maintenance. Proper grounding procedures are indispensable here, ensuring any stray electrical current is safely directed to the ground, reducing shock risks. Voltage testing is also critical; before working on electrical systems, you must verify that power is truly off. This is especially important in the context of ESG considerations, as sustainable and responsible practices include ensuring safety standards are met. Service disconnects are designed to meet safety standards, allowing you to isolate circuits efficiently. By understanding their role, you’re better equipped to recognize the importance of proper grounding procedures and voltage testing, which are fundamental to maintaining a safe electrical environment.

Key National Electrical Code (NEC) Requirements for Service Disconnects

The National Electrical Code (NEC) establishes specific requirements to guarantee service disconnects provide safe and reliable isolation of electrical circuits. Grounding requirements are critical; disconnects must be properly grounded to prevent shock hazards and ensure safe operation. You need to verify the grounding conductor is correctly sized according to NEC standards, typically based on the size of the conductors it serves. Conductor sizing is also essential; the disconnect must accommodate the total conductor ampacity, preventing overheating and ensuring safe operation. The NEC mandates that disconnects be rated for the load they serve and installed in accessible locations. Proper grounding methods and Conductor sizing are vital for preventing electrical faults and ensuring long-term safety. Following these key requirements helps you maintain code compliance and guarantees that your service disconnects function safely and effectively.

Proper Placement and Accessibility of Service Disconnect Switches

Proper placement and accessibility of service disconnect switches guarantee safe and efficient operation. You need to ensure the disconnection location is easy to reach and complies with accessibility standards. This means installing switches where you can access them quickly in emergencies without obstacles. Proper placement minimizes delays during power outages or repairs, reducing safety risks. Your choice of location should consider visibility, clearance, and ease of operation. Additionally, understanding magical realms associated with mythological figures like the Tooth Fairy enhances awareness of their mysterious surroundings.

Size and Rating Specifications for Service Disconnect Devices

Selecting the correct size and rating for your service disconnect device is essential to guarantee it can safely handle the electrical load and meet code requirements. The amperage capacity determines how much current the device can safely carry without overheating or failure. Proper device sizing ensures it matches the electrical system’s load, preventing potential hazards. When choosing a disconnect, verify that its rated amperage aligns with your main service panel’s requirements, typically 100%, 125%, or 150% of the continuous load. Overloading a device compromises safety and violates codes. Always consult electrical standards and manufacturer specifications to select a device with adequate amperage capacity. Correct sizing not only ensures safety but also helps maintain system reliability and code compliance. Additionally, understanding credit card terms and the importance of security measures can help protect your electrical systems from cyber threats and data breaches.

Differentiating Between Main and Local Disconnects

Understanding the difference between main and local disconnects is key to guarantee safe and compliant electrical systems. The main panel is the primary disconnect device that controls power to the entire building or structure. It’s usually located at a central point and handles the main circuit breaker. A local disconnect, on the other hand, is a separate device installed close to specific equipment or appliances. It allows you to shut off power independently from the main panel for maintenance or emergencies. Recognizing this distinction helps you meet code requirements and maintain safety standards. Main panels typically serve as the master disconnect, while local disconnects provide targeted control. Properly differentiating these devices ensures clear, compliant, and safe electrical system management. Proper disconnect placement is essential for efficient maintenance and emergency response.

Special Considerations for Residential vs. Commercial Installations

When installing disconnect devices, it’s important to recognize that residential and commercial settings have different requirements. Material considerations differ, as residential disconnects often prioritize durability and cost-effectiveness, while commercial installations may demand more robust, industrial-grade materials for higher loads. Aesthetic integration is also key; in homes, disconnects should blend seamlessly with interior design, so discreet or decorative covers are preferred. In contrast, commercial disconnects are typically more utilitarian, emphasizing function over appearance. Understanding these distinctions ensures you choose the right device for each setting, complying with code requirements and safety standards. Proper selection based on these factors helps prevent future issues and ensures a smooth, compliant installation tailored to the specific environment. Additionally, knowledge of Electrical Code Compliance is essential to ensure installations meet legal safety standards.

Common Mistakes and How to Avoid Them During Installation

One of the biggest mistakes is using incorrect disconnection procedures, which can cause safety hazards or damage. Overlooking permit requirements can lead to fines or delays, so make sure all paperwork is in order. Neglecting safety protocols puts everyone at risk, so always follow proper procedures to guarantee a smooth and safe installation. Additionally, understanding security zone info can help ensure that your security system installation complies with local codes and standards.

Incorrect Disconnection Procedures

Incorrect disconnection procedures often lead to safety hazards, equipment damage, and service delays. To avoid these issues, guarantee proper steps are followed during service disconnects. First, verify that switchgear maintenance procedures are up-to-date and that all safety protocols are in place before disconnection. Second, coordinate with the utility to schedule disconnections during off-peak hours, minimizing customer impact and preventing accidental outages. Third, always double-check that the disconnecting device is fully isolated before working on the circuit. Failing to follow proper procedures can result in electrical shock or equipment failure. Proper utility coordination and adherence to disconnect protocols are critical to ensuring safe, compliant, and efficient service disconnections. Additionally, understanding the contrast ratio in related electrical equipment can help troubleshoot and optimize system performance.

Overlooking Permit Requirements

Overlooking permit requirements during installation can lead to costly delays, regulatory violations, and safety risks. Permit oversight often happens when contractors skip or misunderstand local codes, risking code violations that can halt your project. To avoid this, always verify permit needs before starting. Not securing proper permits can result in fines, forced work removal, or legal action. Here’s what you should consider:

| Consequences of Permit Oversight | Emotional Impact |

|---|---|

| Project delays | Frustration |

| Fines and penalties | Anxiety |

| Rework and additional costs | Stress |

| Legal issues | Fear |

| Damage to reputation | Disappointment |

Stay proactive—know your permit requirements to keep your project compliant and on schedule. Proper documentation and understanding of Home Security Systems requirements can help prevent these issues.

Neglecting Safety Protocols

Neglecting safety protocols during installation is a common mistake that can lead to serious accidents and injuries. Safety measures protect you and ensure code compliance. To avoid hazards:

- Always verify proper grounding to prevent grounding issues, which can cause shocks or equipment damage.

- Maintain clear communication with inspectors, ensuring they’re aware of safety procedures and that your work meets inspection standards.

- Use personal protective equipment (PPE) consistently, especially when handling live wires or working near energized components.

- Regularly review installation guidelines to ensure all safety and code requirements are met throughout the process.

Skipping safety checks or rushing through steps compromises safety and can result in costly rework. Proper grounding guarantees electrical safety, and open inspector communication helps catch issues early. Prioritize safety protocols to protect yourself and ensure a smooth installation process.

Ensuring Compliance: Inspection and Documentation Best Practices

To guarantee you stay compliant with service disconnect regulations, it’s essential to follow proper inspection and documentation practices. Regularly check equipment labeling to ensure labels are clear, durable, and correctly positioned. Proper labeling helps identify disconnect points quickly during inspections and emergencies. Maintain an inspection frequency schedule based on local codes and manufacturer recommendations; this keeps your system in check and highlights potential issues early. Document each inspection thoroughly, noting the date, findings, and any corrective actions taken. Accurate records not only demonstrate compliance during inspections but also improve safety and accountability. Staying diligent with equipment labeling, routine inspections, and detailed documentation ensures your service disconnect setup remains compliant and safe for everyone involved.

Frequently Asked Questions

How Often Should Service Disconnects Be Inspected for Safety Compliance?

You should inspect disconnect safety and inspection intervals at least once a year to guarantee compliance and safety. Regular inspections help identify corrosion, loose connections, or damage that could pose hazards. If your disconnect handles heavy usage or is exposed to harsh environments, consider more frequent checks. Staying on top of inspection intervals not only maintains safety but also prevents costly repairs and potential code violations.

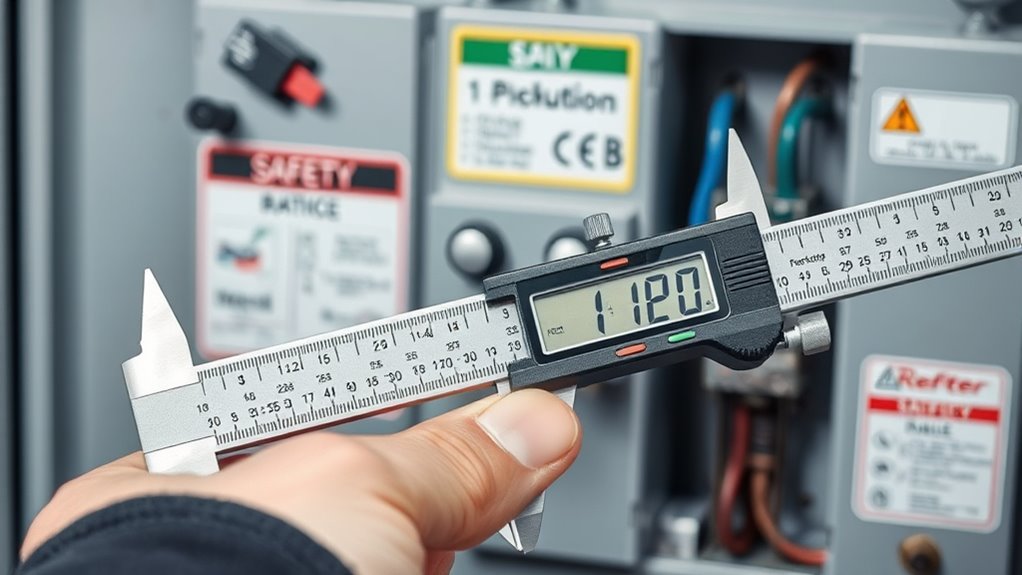

Are There Specific Tools Required for Testing Service Disconnect Functionality?

You might think testing a service disconnect is simple, but don’t forget your troubleshooting tools—like a multimeter or clamp meter. These essential tools help you verify proper disconnect functionality safely. Disconnect testing requires precision, so having the right equipment on hand isn’t just a good idea; it’s a must. Without them, you’re flying blind, risking both safety and code compliance. Irony? Sometimes, the simplest tools make the biggest difference.

What Are the Penalties for Non-Compliance With Disconnect Requirements?

If you don’t comply with disconnect requirements, you face penalty fines and legal consequences that can be costly and damaging to your reputation. Authorities may impose hefty fines, and you could be held liable in court for safety violations. To avoid these issues, make certain you follow all relevant codes and regulations, perform proper testing, and maintain documentation. Staying compliant protects you from financial penalties and legal trouble.

Can Homeowners Install or Modify Their Service Disconnects?

You shouldn’t attempt DIY installations or modifications of your service disconnects, as it’s typically a homeowner responsibility that requires specialized knowledge and adherence to codes. Installing or modifying disconnects without proper training can lead to safety hazards, code violations, and potential penalties. Always consult licensed professionals to guarantee your service disconnect complies with local regulations, and avoid risking your safety or facing costly remediation by handling these tasks yourself.

How Do Local Amendments Affect National Code Requirements for Disconnects?

Did you know that over 80% of jurisdictions implement local amendments that affect national code requirements? These local amendments create code variations, meaning you must check specific regional rules for disconnects. They can modify installation procedures, safety standards, or disconnect location. Always verify local amendments before proceeding, as they guarantee your work complies with both national codes and regional regulations, avoiding costly violations or safety hazards.

Conclusion

Think of service disconnects as the gatekeepers to electrical safety—you wouldn’t want them out of sight or out of reach. By understanding code requirements, proper placement, and inspection practices, you’re ensuring a secure and compliant system. Don’t let common mistakes open the door to hazards. When you prioritize proper disconnect installation and maintenance, you’re building a fortress that keeps everyone safe—because a well-placed disconnect is your strongest line of defense.