To guarantee your cold weather kits for standby units meet codes and compliance, you must focus on critical calculations like heating requirements, insulation specifications, and power backup capacities. Assess industry standards from NFPA and IEC, and verify local regulations for insulation, ventilation, and electrical safety. Proper documentation of calculations and ongoing inspections are essential. By following these steps, you can confidently meet compliance standards—keep exploring to uncover the detailed processes involved.

Key Takeaways

- Ensure cold weather kits comply with NFPA, IEC, and local safety standards to meet legal and operational requirements.

- Conduct precise heat loss calculations considering insulation, ventilation, and environmental factors to size heating systems correctly.

- Verify that backup power solutions, including batteries and generators, are weatherproof and capable of sustained cold-weather operation.

- Maintain detailed documentation of compliance measures, inspection records, and testing results for audits and continuous adherence.

- Incorporate thermal insulation, moisture barriers, and frost prevention components aligned with industry regulations for reliable standby unit performance.

Understanding Relevant Industry Standards and Regulations

To guarantee your standby units operate reliably in cold weather, it is essential to understand the industry standards and safety regulations that govern their design and deployment. Industry standards provide essential guidelines for ensuring your units can withstand low temperatures, prevent freezing, and operate efficiently. Safety regulations set the minimum requirements to protect personnel and equipment during installation and operation. Familiarizing yourself with standards from organizations like the National Fire Protection Association (NFPA) or the International Electrotechnical Commission (IEC) helps guarantee compliance and safety. Adhering to these regulations minimizes risks, avoids legal issues, and assures that your standby units perform at their best under cold conditions. Staying informed about current standards ensures your equipment remains compliant and reliable, especially when harsh winter weather hits. Understanding relevant industry standards is crucial for designing and maintaining compliant and resilient standby units.

Identifying Critical Components for Cold Weather Operation

To guarantee your standby units operate effectively in cold weather, you need to identify the critical components that can withstand low temperatures. Focus on essential heating equipment, reliable power sources, and cold-resistant parts that prevent failures. By selecting the right elements, you can keep your system running smoothly despite the chill. Additionally, understanding the impact of environmental factors on equipment durability can help you plan for unexpected cold weather challenges.

Essential Heating Equipment

What are the key components that guarantee standby units operate effectively in cold weather? Essential heating equipment is critical. You need reliable heating elements that can maintain ideal temperatures despite low outdoor temperatures. Proper thermal insulation surrounds the equipment, reducing heat loss and ensuring energy efficiency. Moisture barriers are equally important; they prevent condensation buildup that could damage sensitive components or cause corrosion. These barriers keep moisture out, maintaining the integrity of the system. Additionally, using high-efficiency heating systems can further enhance performance in cold conditions. Together, thermal insulation and moisture barriers protect the unit from cold-related stress, ensuring continuous operation. Investing in high-quality heating equipment with these features helps you meet code requirements and maintains reliable performance during harsh winter conditions.

Reliable Power Sources

Reliable power sources are essential for standby units to operate effectively in cold weather conditions. Without consistent energy, critical systems may fail when you need them most. To guarantee dependability, consider integrating diverse power options, including a solar backup, which provides renewable energy during outages. Emergency preparedness relies on backup generators that can withstand low temperatures and maintain continuous operation. Incorporating high-performance projectors with cold-weather capabilities can also enhance operational reliability in extreme conditions.

Key components to focus on include:

- Solar backup systems for sustainable, renewable power

- Cold-resistant batteries designed for low temperatures

- Automatic transfer switches for seamless power switching

- Generators with weatherproof enclosures

- Proper wiring and insulation for cold resilience

These elements help you maintain reliable power, ensuring your standby units are operational during winter emergencies.

Cold-Resistant Components

When operating standby units in cold weather, choosing the right cold-resistant components is essential for ensuring continuous performance. These components help prevent frost damage and maintain peak functioning. Key elements include thermal insulation to protect sensitive parts and frost prevention measures like heating elements. Consider the following critical components:

| Component | Purpose |

|---|---|

| Insulated Enclosures | Reduce heat loss |

| Frost Heaters | Prevent ice formation |

| Sealed Connectors | Protect against moisture |

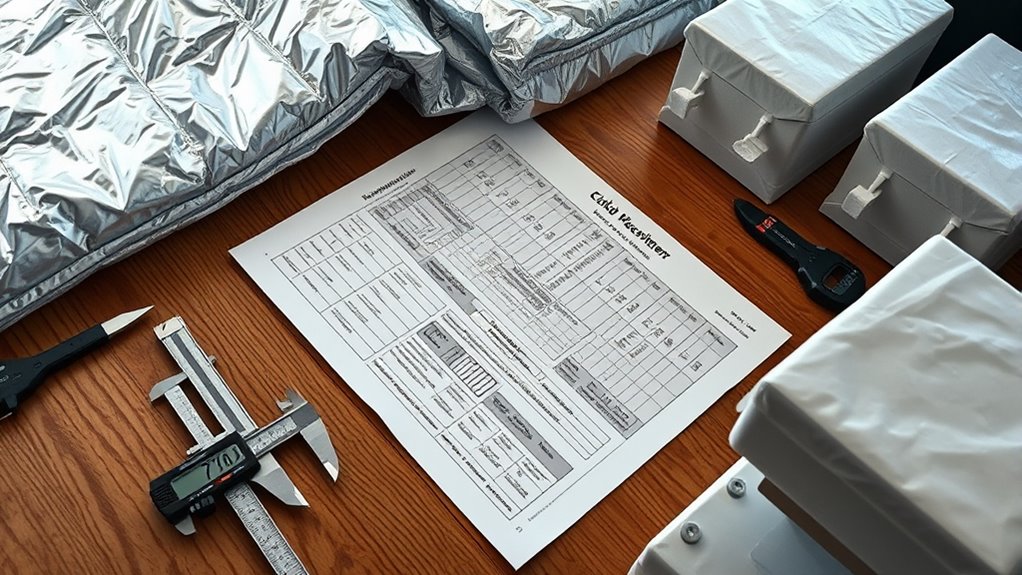

Calculating the Heating Requirements for Standby Units

To guarantee your standby units stay operational in cold weather, you need to accurately calculate their heating requirements. Start by evaluating heat loss factors, such as insulation and ventilation, that impact how much heat is needed. Then, determine the appropriate heating capacity to keep your units warm and functional at all times. Additionally, considering the use of eye patches can help maintain alertness and reduce fatigue during long monitoring periods in cold environments.

Assessing Heat Loss Factors

Evaluating heat loss factors is a crucial step in determining the heating requirements for standby units. You need to contemplate how heat escapes through various elements, including thermal bridging, which can create weak points where heat transfers more rapidly. Proper airflow management helps reduce unnecessary heat loss by controlling ventilation and drafts. To accurately assess heat loss, focus on:

- Insulation quality and placement

- Thermal bridging points

- Air leakage sites

- Ventilation efficiency

- Surface temperatures of exterior walls

Determining Heating Capacity

How do you determine the appropriate heating capacity for standby units? Start by analyzing ventilation requirements, as proper airflow impacts heat loss. You need to take into account the ambient temperature, especially during cold weather, since lower temperatures increase heating demands. To calculate the required capacity, first estimate the heat loss based on insulation levels, surface area, and ventilation rates. Then, adjust for the lowest expected ambient temperature to guarantee reliable operation. Don’t forget to factor in safety margins for unexpected temperature drops or increased ventilation needs. Accurate calculations help prevent undersizing, which risks equipment failure, or oversizing, which leads to unnecessary energy use. By closely evaluating these factors, you’ll select a standby unit with the right heating capacity to maintain ideal conditions. Additionally, understanding celery juice powder can be beneficial if considering natural preservatives or supplements to support overall operational health.

Determining Insulation and Enclosure Specifications

When determining insulation and enclosure specifications for standby units in cold weather, you need to contemplate the specific temperature ranges the equipment will face and the environmental conditions of the installation site. Your focus should be on selecting suitable insulation materials and designing enclosures that prevent heat loss and moisture intrusion. Consider these factors:

- R-value requirements based on temperature extremes

- Compatibility of insulation materials with outdoor environments

- Enclosure designs that provide adequate ventilation and sealing

- Material durability against moisture, snow, and ice

- Ease of access for maintenance and inspections to ensure proper functionality.

Assessing Power Supply and Backup Capabilities

Ensuring reliable power supply and backup capabilities is essential for standby units operating in cold weather conditions. You need to evaluate your power source’s capacity to handle peak loads, especially when temperatures drop and demand increases. Battery backup systems are critical; they provide immediate power if the main supply fails. Examine the battery’s capacity and lifespan to guarantee it can sustain operation during outages. Power redundancy is also vital—having multiple power sources or backup units minimizes the risk of failure. Regular testing of backup systems confirms their readiness and guarantees they function properly in cold conditions. By thoroughly assessing these aspects, you can prevent unexpected outages, maintain operational integrity, and meet safety standards during harsh winter weather. Inverter generator efficiency can also impact overall backup reliability, especially in cold environments.

Verifying Compliance With Local and International Codes

Verifying compliance with local and international codes is a critical step in preparing standby units for cold weather operations. Guaranteeing your setup meets these regulations helps maintain outdoor safety and minimizes environmental impact. To do this effectively, you should:

- Check local building codes and safety standards

- Confirm adherence to international environmental regulations

- Verify proper insulation and ventilation requirements

- Ensure electrical installations comply with safety codes

- Document all compliance measures for inspections

- Utilize trailer music insights to understand how industry standards influence compliance practices.

This process protects you from legal issues, enhances outdoor safety, and reduces environmental harm. Staying up-to-date with applicable codes ensures your cold weather kits are both effective and compliant, supporting safe, eco-conscious operations. Skipping this step could lead to safety hazards or regulatory penalties, so thorough verification is essential.

Documenting and Validating Your Cold Weather Kit Calculations

Accurately documenting and validating your cold weather kit calculations is essential to guarantee your setup performs reliably under low temperatures. Start by recording all calculation data, including temperature monitoring results and environmental conditions, to create a clear record of your process. Validation involves testing your kit under simulated cold conditions to ensure it meets the required performance standards. Keep detailed logs of these tests and the results, highlighting any adjustments made. Proper documentation supports compliance with codes and helps in troubleshooting. Additionally, ensure your emergency procedures incorporate temperature monitoring alerts, so you can respond promptly if conditions threaten your system’s integrity. Understanding environmental factors is crucial when preparing for low-temperature challenges. By systematically documenting and validating your calculations, you establish a reliable foundation for your cold weather setup that withstands low-temperature challenges.

Regular Inspection and Maintenance to Ensure Ongoing Compliance

Regular inspection and maintenance are critical to keeping your cold weather kit compliant and functioning effectively over time. Regularly check seasonal equipment to guarantee it’s in good condition, and verify that all components meet safety standards. Train your staff regularly to keep everyone familiar with inspection procedures and proper handling. Maintain detailed records of inspections and repairs to document ongoing compliance. Schedule routine maintenance to prevent equipment failures during critical periods. Keep an eye out for signs of wear and tear, replacing items as necessary. Ensure staff understands the importance of proper storage and handling of cold weather gear. Consistent upkeep reduces the risk of non-compliance and guarantees your standby units are ready when needed. Remember, proactive maintenance saves time and resources in the long run.

Frequently Asked Questions

How Often Should Cold Weather Kits Be Recalculated for Compliance?

You should recalculate cold weather kits annually to guarantee compliance with insulation standards and weatherproofing techniques. Regular checks help you identify any deterioration or changes that could affect performance during cold conditions. By staying proactive, you ensure your standby units remain reliable and meet safety regulations. Incorporate these recalculations into your maintenance routine, especially before winter, to keep your equipment resilient against harsh weather and maintain proper compliance.

What Are Common Mistakes in Calculating Heating Requirements?

You often make mistakes in calculating heating requirements by neglecting insulation efficiency, which can lead to underestimating needed heat. Always factor in insulation’s impact, as poor insulation reduces efficiency and increases fuel consumption. Avoid overlooking fuel optimization; this helps ensure your cold weather kits provide sufficient heat without waste. Double-check your calculations regularly to account for changing conditions, and stay compliant with codes and safety standards.

How Do Local Climate Variations Affect Kit Specifications?

You should consider climate impact and regional standards when specifying your cold weather kits, as local climate variations considerably influence heating needs. In colder regions, you’ll need more robust insulation and heating capacity, while milder climates require less. Always check regional standards to ensure compliance, and adjust kit specifications accordingly, so your standby units operate reliably regardless of climate fluctuations. Properly tailored kits prevent failures and ensure safety during extreme weather conditions.

Are There Specific Certifications Required for Cold Weather Components?

Yes, there are specific certifications required for cold weather components. You need to guarantee that your components meet certification requirements like UL or IEC standards, which verify their ability to operate reliably in low temperatures. Adhering to component standards is essential for compliance and safety. Always check local regulations, and select components with proper certification labels to avoid issues during inspections and to ensure peak performance in cold conditions.

How Can I Verify Ongoing Compliance After Initial Installation?

Think of compliance as a garden that needs regular tending. You can verify ongoing compliance by setting up automatic testing systems that monitor your cold weather kits continuously. Regular maintenance scheduling is also key; it guarantees the components remain in top condition. Keep detailed records of inspections and tests, and review them periodically. This proactive approach helps you catch issues early and stay in line with codes and standards.

Conclusion

By carefully calculating and following industry standards, you build a cold weather kit that’s as solid as a fortress against the chill. Don’t let overlooked details freeze your operations—stay vigilant with regular checks and updates. Remember, compliance isn’t just a rule; it’s the backbone that keeps your standby units running smoothly through winter’s worst. When it comes to cold weather readiness, thoroughness is your best shield—keep your plans airtight, and the cold won’t stand a chance.