To handle overcrank faults safely, recognize early warning signs like unusual noises or increased resistance and don’t force the equipment. Follow established safety procedures, such as regular inspections, proper handling, and emergency protocols like automatic shut-offs. Proper training and routine checks help you prevent faults and respond swiftly if they occur. Staying alert and prepared is key—continue exploring these safety strategies for more effective solutions that truly work.

Key Takeaways

- Recognize early signs such as unusual noises or resistance to prevent overcrank faults.

- Establish and enforce clear safety protocols and emergency shut-off procedures for all personnel.

- Conduct routine equipment inspections, checking for loose connections, worn parts, and proper lubrication.

- Train staff on proper operation, troubleshooting, and emergency response to quickly address faults.

- Limit unnecessary overcranking and schedule maintenance during low-traffic periods to reduce risk.

Understanding Overcrank Faults and Their Risks

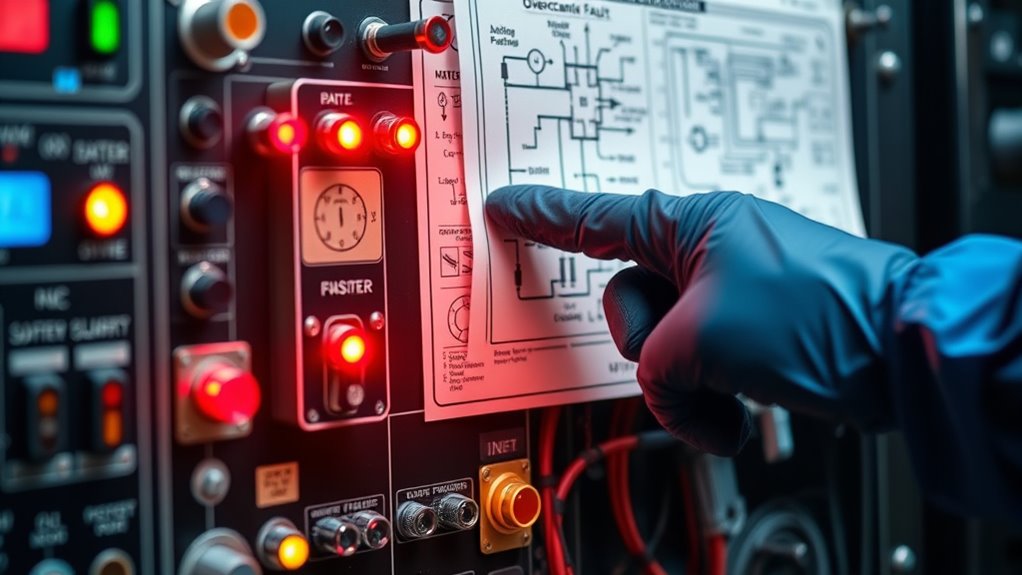

Overcrank faults occur when a crane’s winch or hoisting mechanism continues to turn after the load has reached its desired position. Recognizing these faults quickly is vital for safe operation. Overcrank diagnostics help you identify the issue early, preventing unnecessary wear or damage to equipment. When a fault occurs, it’s important to understand its risks, such as potential load drops or mechanical failure. Fault mitigation strategies, like automatic shut-offs or safe braking systems, can stop overcranking before it causes harm. Regularly checking your crane’s control systems and sensors ensures overcrank faults are detected promptly. Implementing preventive maintenance routines can further reduce the likelihood of faults occurring unexpectedly. By understanding the importance of diagnostics and mitigation, you can maintain safer work environments and extend the lifespan of your crane’s components.

Common Causes of Overcrank Faults in the Field

Many common issues in the field can trigger overcrank faults, often stemming from equipment or operator errors. Hardware malfunctions, such as worn-out sensors or faulty relays, can send incorrect signals, causing the system to shut down prematurely. Loose connections or damaged wiring also disrupt communication, leading to overcrank faults. Operator errors, like failing to follow proper startup procedures or over-pressing start buttons, can overload the system. Misjudging load conditions or neglecting routine maintenance increases the risk of faults caused by hardware issues or improper operation. Additionally, understanding contrast ratio and its impact on image quality can help prevent misdiagnosis of projector faults. Identifying these causes helps you troubleshoot effectively and avoid unnecessary downtime. Staying vigilant about equipment health and adhering to operational protocols are key to minimizing overcrank faults in the field.

Recognizing Signs and Preventing Overcrank Incidents

By paying close attention to specific operational cues, you can often spot early warning signs of potential overcrank incidents. Unusual noises, delayed responses, or increased resistance during operation are key indicators. If you notice these signs, avoid forcing the equipment; instead, utilize manual overrides to gently correct the issue. Always be familiar with your facility’s emergency protocols so you can respond swiftly if a fault occurs. Preventive measures include regular equipment checks and proper training to recognize signs of overcrank stress. Being aware of equipment safety protocols can further enhance your response effectiveness. By staying alert and proactive, you reduce the risk of incidents, ensuring safety for yourself and your team. Recognizing these signs early and knowing how to respond can make all the difference in avoiding costly or dangerous overcrank faults.

Effective Safety Procedures to Avoid Overcrank Faults

Implementing effective safety procedures is essential for preventing overcrank faults before they occur. Start by establishing clear safety protocols that everyone understands and follows consistently. These protocols should include routine equipment inspections, proper handling techniques, and limiting unnecessary overcranking. Ensure that all workers know how to recognize early warning signs of potential faults. Additionally, prepare an emergency response plan so you can act swiftly if an issue arises. This plan should include immediate shut-off procedures, communication channels, and safety gear usage. Regularly review and update these procedures, keeping safety at the forefront. For instance, understanding retail hours today can help schedule maintenance during low-traffic periods, reducing the risk of faults during busy times. By prioritizing safety protocols and having a solid emergency response plan, you considerably reduce the risk of overcrank faults and protect everyone involved.

Training and Equipment Checks for Long-Term Safety

Consistent training and thorough equipment checks are essential for maintaining long-term safety and preventing overcrank faults. Regular maintenance routines help identify wear and potential issues before they cause problems, ensuring your equipment functions reliably. Make sure everyone involved understands emergency protocols so they can respond swiftly if a fault occurs. Incorporate routine inspections into your schedule, checking for loose connections, worn parts, and proper lubrication. Training should cover both standard operations and emergency procedures, reinforcing safe handling and troubleshooting techniques. Additionally, understanding the water attractions available at various parks can help staff better prepare for safety concerns related to water slides and pools. By staying proactive with maintenance routines and ensuring everyone is well-versed in emergency protocols, you reduce the risk of overcrank faults and create a safer work environment over time.

Frequently Asked Questions

How Often Should Safety Protocols Be Reviewed for Overcrank Faults?

You should review safety protocols for overcrank faults at least every six months or whenever there’s a significant change in equipment or procedures. Regular maintenance schedules help guarantee protocols stay current, and employee feedback offers valuable insights into potential hazards. By actively updating safety measures based on these reviews, you reduce risks and promote a safer work environment, keeping everyone well-informed and prepared for overcrank fault situations.

What Are the Latest Technological Tools for Detecting Overcrank Risks?

You should consider using advanced tools like sensor integration combined with predictive analytics to detect overcrank risks early. Sensors monitor real-time data on machinery, alerting you to potential faults before they escalate. Predictive analytics analyzes this data, identifying patterns and predicting failures. Together, these technologies enable proactive maintenance, reduce downtime, and enhance safety, making overcrank fault detection more accurate and efficient.

Are There Industry-Specific Overcrank Safety Standards?

Yes, industry-specific overcrank safety standards exist to help you maintain safe operations. You should follow these standards and seek safety certifications relevant to your sector, ensuring your equipment and procedures meet established guidelines. These standards provide clear protocols for preventing overcrank faults, protecting workers, and reducing risks. Staying compliant with industry standards and obtaining safety certifications demonstrates your commitment to safety and helps you operate responsibly.

How Can Workers Report Potential Overcrank Hazards Anonymously?

Reporting potential overcrank hazards is like passing a secret note—you want your message to stay private. You can do this through anonymous reporting channels, such as dedicated hotlines or online forms, ensuring your hazard communication remains confidential. These methods protect your identity and encourage prompt reporting, helping prevent accidents. Always familiarize yourself with your company’s procedures to confidently report hazards anonymously and contribute to a safer work environment.

What Are the Most Common Mistakes During Safety Training Sessions?

You often overlook miscommunication gaps and complacency risks during safety training sessions. To avoid mistakes, make sure you’re clear and concise, engaging all participants actively. Repeating key safety points and encouraging questions helps prevent misunderstandings. Avoid rushing through topics or assuming knowledge. Regularly refresh training and emphasize real-world scenarios. By staying attentive to these areas, you’ll improve safety awareness and reduce errors that could lead to hazards.

Conclusion

By staying alert and following safety procedures, you’ll spot overcrank faults before they happen—like catching a subtle wobble in your equipment’s rhythm. Regular checks and proper training become your safety net, preventing incidents from unfolding unexpectedly. When you combine vigilance with routine maintenance, it’s as if you’re silently steering a well-oiled machine through a smooth, fault-free operation. In this coincidence of care and caution, safety naturally becomes second nature.