To avoid low voltage output issues, you should guarantee proper wiring, avoid undervaluing voltage drop calculations, choose high-quality components, regularly check power stability, inspect grounding and bonding, manage environmental factors, calibrate equipment correctly, prevent circuit overloads, and never skip routine maintenance. Each mistake can cause voltage drops, system failure, or safety hazards. Staying vigilant on these points helps maintain consistent voltage levels. Keep going to discover detailed tips on each of these essential areas.

Key Takeaways

- Proper wiring, connections, and regular inspections prevent resistance buildup and voltage drops.

- Calculating voltage drops and calibrating equipment ensures stable voltage output.

- Using high-quality components reduces risks of fluctuations and system failure.

- Managing environmental factors like temperature and humidity maintains consistent voltage levels.

- Avoid overloading circuits and perform routine maintenance to prevent voltage instability and equipment damage.

Ignoring Proper Wire Sizing and Connections

Ignoring proper wire sizing and connections can substantially reduce your low voltage output. If you use the wrong wire gauge, your system faces increased resistance, leading to voltage drops and decreased efficiency. Thinner wires may seem easier to install, but they can’t handle the current, causing overheating and power loss. Equally important is connection quality; loose or corroded connections create resistance, further lowering voltage and risking system failure. Always verify your wires are appropriately gauged for the load and that connections are tight and secure. Properly sized wires with high-quality connections help maintain consistent voltage levels, ensuring your system works at peak efficiency. Neglecting these factors might save time initially but ultimately hampers your low voltage output and system reliability. Additionally, correct wiring techniques are essential to prevent potential safety hazards and ensure system longevity.

Overlooking Voltage Drop Calculations

Failing to perform voltage drop calculations can considerably undermine your low voltage system’s performance. When you overlook these calculations, you risk poor voltage regulation, which can cause equipment malfunction or damage. Voltage drops occur when current travels through wiring resistance, reducing voltage at the load point. By properly calculating voltage drop, you ensure your wiring is adequate for the current draw, maintaining steady voltage levels. Proper wire sizing and load capacity are essential to prevent overloads and ensure safety. This also helps identify where power factor correction might be necessary to improve efficiency and reduce losses. Ignoring these calculations can lead to unnecessary energy waste and system instability. Always factor in voltage drop during design and installation. Doing so guarantees your system operates reliably, with consistent voltage levels and desirable performance.

Using Faulty or Low-Quality Components

Using faulty or low-quality components can considerably compromise your low voltage system’s reliability and safety. When selecting components, prioritize quality and durability to prevent unexpected failures. Poor material quality often leads to increased resistance, overheating, or even short circuits, risking damage to your entire setup. Inadequate component selection can cause voltage fluctuations or power loss, undermining system performance. Always choose reputable brands and verify specifications to ensure compatibility. Skimping on component quality might save money initially, but it can lead to costly repairs and safety hazards down the line. Investing in high-quality components ensures your system operates efficiently, maintains stable output, and reduces troubleshooting time. Proper component selection is critical in maintaining system stability and longevity. Remember, quality components are the foundation of a safe, reliable low voltage system.

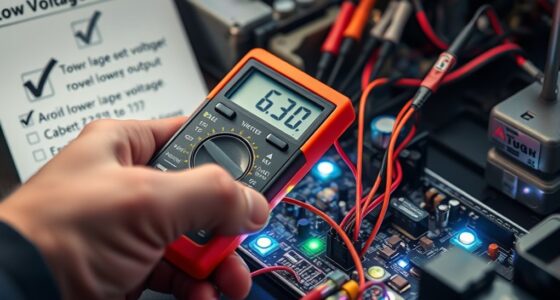

Failing to Check Power Supply Stability

Ensuring your power supply remains stable is essential for maintaining consistent low voltage output. If you overlook checking for power supply noise, you risk introducing unwanted signals that can cause voltage fluctuation. These fluctuations can lead to unstable performance or damage sensitive components. Regularly monitor your power supply for signs of instability, such as irregular voltage levels or increased noise. Using proper measurement tools, like an oscilloscope, helps identify subtle power supply noise that might not be visible on standard meters. Addressing any instability promptly ensures your system maintains a steady voltage, preventing issues caused by fluctuating power. power supply noise can be a subtle but significant factor affecting voltage stability. Don’t ignore the importance of verifying power supply stability; it’s a crucial step in avoiding low voltage output problems.

Neglecting to Inspect Grounding and Bonding

You need to regularly check ground connections to make certain they’re secure and free of corrosion. Verifying the bonding integrity helps prevent voltage issues and safety hazards. Establishing a regular inspection schedule keeps your system reliable and safe from hidden grounding problems. Being aware of narcissistic behaviors can also help identify potential issues early on.

Check Ground Connections

Neglecting to inspect grounding and bonding connections can lead to low voltage output issues. Loose or improper ground connections create a ground loop, causing voltage fluctuations. To prevent this, check all ground wires for tightness and proper attachment. Ensure grounding points are clean and free of corrosion. Use the table below to verify key connection points:

| Connection Point | Issue to Watch For | Corrective Action |

|---|---|---|

| Main Ground Bonding | Loose or corroded connection | Tighten or clean connection |

| Equipment Grounds | Unsecured wires | Secure firmly |

| Ground Bus Bar | Rust or debris | Clean and tighten |

| Grounding Rods | Poor contact or corrosion | Replace or clean |

| Ground Loop Prevention | Multiple ground paths | Minimize loops |

Addressing these areas reduces the risk of ground loops and ensures stable voltage. Regular inspection of grounding and bonding is essential for maintaining consistent low voltage output.

Verify Bonding Integrity

One common mistake that can cause low voltage output is failing to verify the integrity of bonding connections. Proper grounding standards emphasize solid bonding techniques to ensure a low-resistance path for fault currents. If bonds are loose, corroded, or improperly installed, voltage levels can drop unexpectedly. Use a reliable test method to check that all bonding connections are secure and meet grounding standards. Inspect bonding conductors for signs of damage or corrosion, and confirm that connections are tight and continuous. Neglecting this step can lead to voltage irregularities, equipment malfunction, or safety hazards. Regularly verifying bonding integrity helps maintain system performance and guarantees compliance with electrical codes. Additionally, innovative materials used in grounding systems can enhance durability and conductivity. Don’t overlook this essential step in troubleshooting low voltage issues.

Regular Inspection Schedule

Establishing a regular inspection schedule is essential for maintaining the integrity of grounding and bonding systems. You should routinely check circuit breakers to ensure they trip properly, preventing overloads that could compromise grounding. Inspect wire insulation for cracks, cuts, or wear, as damaged insulation can lead to poor grounding connections. Neglecting these inspections may result in loose or corroded connections, increasing the risk of voltage fluctuations or faults. Regularly verify that grounding conductors are secure and free from corrosion. Additionally, understanding the importance of grounding and bonding in electrical safety can help you prioritize proper maintenance. By systematically inspecting circuit breakers and wire insulation, you reduce the chances of unnoticed issues that can cause low voltage output. Staying proactive with your inspections helps you maintain a safe, reliable electrical system and prevents costly failures.

Ignoring Environmental Factors Affecting Voltage

You might overlook how temperature changes can cause voltage fluctuations, especially in extreme conditions. Humidity and corrosion can degrade connections, leading to inconsistent output. Additionally, airflow disruptions can cause overheating or moisture buildup, impacting your system’s performance. Proper ventilation ensures airflow management, helping to maintain stable voltage levels.

Temperature Variations Impact

Temperature fluctuations can markedly influence low voltage output, yet many overlook their impact. Variations in ambient temperature cause components to expand or contract, leading to voltage inconsistencies. To mitigate this, focus on:

- Maintaining proper humidity control to prevent condensation and moisture-related issues.

- Using thermal insulation to stabilize temperature around sensitive components.

- Ensuring consistent airflow to avoid temperature spikes.

- Regularly monitoring environmental conditions to identify temperature shifts early.

- Selecting appropriate connectors that are less susceptible to temperature-related issues can further enhance system stability.

Neglecting these factors can cause voltage drops or surges, risking device performance. By controlling environmental conditions, especially temperature, you protect your equipment and ensure stable output. Remember, even minor temperature changes can considerably impact low voltage systems if environmental factors aren’t managed properly.

Humidity and Corrosion

Ignoring humidity levels can lead to corrosion in low voltage systems, causing unpredictable voltage fluctuations and potential component failures. When humidity rises, dew formation can occur on contacts and circuit boards, creating a moisture layer that accelerates corrosion. Salt buildup is another concern, especially in coastal areas, where salt particles in the air settle on electrical parts, intensifying corrosion risks. This corrosion degrades connections, increases resistance, and disrupts voltage stability. Regularly monitoring humidity levels and protecting your equipment from moisture exposure can prevent these issues. Applying sealants or corrosion-resistant coatings also helps shield sensitive components. By addressing environmental factors like humidity, you can maintain consistent voltage output and extend the lifespan of your low voltage system.

Airflow Disruptions

When humidity and corrosion issues aren’t addressed, environmental factors like airflow disruptions can worsen voltage stability. Poor airflow management hampers proper heat dissipation, causing components to overheat and drop voltage levels. To improve ventilation efficiency, consider these vital points:

- Ensure unobstructed airflow paths around equipment.

- Use fans or vents to promote consistent air circulation.

- Regularly clean filters and vents to prevent blockages.

- Position devices to avoid airflow turbulence or stagnation.

Ignoring these factors can lead to temperature spikes, which reduce voltage output and damage sensitive components. Maintaining proper airflow management is crucial for stable voltage performance, especially in environments with fluctuating temperatures. Prioritize ventilation efficiency to minimize environmental disruptions and safeguard your equipment’s voltage stability.

Improperly Configuring or Calibrating Equipment

Properly configuring and calibrating your equipment is essential to guarantee accurate low voltage output. If your calibration procedures are incomplete or inconsistent, you risk inaccurate readings, which can cause system malfunctions. Double-check your equipment configuration to ensure all connections are correct and settings are properly adjusted. Use manufacturer guidelines for calibration procedures, and document each step for future reference. Neglecting proper calibration can lead to voltage fluctuations and unreliable performance. Take the time to verify that your instruments are calibrated regularly and correctly, especially after maintenance or adjustments. Accurate calibration and correct equipment configuration help maintain stable voltage output, preventing issues caused by misaligned or poorly set up equipment. This proactive approach saves you troubleshooting time and improves overall system reliability.

Overloading Circuits or Devices

Overloading circuits or devices can considerably impact low voltage output, leading to voltage drops and system instability. When you push a circuit beyond its capacity, it strains the power supply and compromises circuit protection. To prevent this, consider these points:

Overloading circuits causes voltage drops and system instability; ensure proper protection and device compatibility.

- Ensure devices are compatible with your system’s voltage and current ratings.

- Avoid connecting multiple high-power devices to a single circuit.

- Use proper fuse ratings or circuit breakers to safeguard against overloads.

- Regularly check wiring and connections for signs of wear or overload stress.

Overloading not only risks damaging equipment but also causes voltage fluctuations that affect overall performance. Maintaining device compatibility and implementing adequate circuit protection are essential to keep your low voltage system stable and reliable.

Skipping Regular Maintenance and Testing

Neglecting regular maintenance and testing can silently undermine your low voltage system’s stability. Without routine checks, issues like loose connections or worn components go unnoticed, risking failures. Use diagnostic tools to identify potential problems early and review maintenance records to track system health. Visualize this process with the following:

| Inspection Focus | Benefits |

|---|---|

| Diagnostic tools | Detect hidden faults |

| Maintenance records | Preventative maintenance |

| Visual checks | Spot physical damage |

| Testing schedules | Ensure consistent performance |

Skipping these steps leaves your system vulnerable to sudden breakdowns. Regular testing keeps your system reliable, saves money, and extends equipment lifespan. Don’t wait for a failure—stay proactive and keep your low voltage system running smoothly.

Frequently Asked Questions

Can Firmware Issues Cause Low Voltage Output Problems?

Yes, firmware glitches can cause low voltage output problems. When the firmware isn’t functioning correctly, it can disrupt voltage regulation processes, leading to unstable or insufficient power delivery. You should make certain your firmware is up to date and properly installed. If issues persist, consider re-flashing or updating the firmware to fix bugs that may be causing voltage regulation issues, ultimately improving your device’s voltage output stability.

How Does Electromagnetic Interference Impact Voltage Stability?

Electromagnetic interference (EMI) can disrupt voltage stability by introducing unwanted signals into your system. When EMI occurs, it compromises electromagnetic compatibility, leading to fluctuations and noise in your low voltage output. To prevent this, you should use shielding techniques like grounded enclosures and twisted pairs to block interference. Proper shielding guarantees your system maintains stable voltage levels, avoiding performance issues caused by electromagnetic disturbances.

Are There Specific Safety Protocols for Low Voltage Systems?

Yes, you should follow safety protocols like avoiding ground loops and inspecting for insulation failure. Ground loops can cause unexpected voltage fluctuations, so verify proper grounding practices. Regularly check insulation to prevent electrical shorts, which pose safety risks. Use appropriate protective gear and follow manufacturer guidelines. Keep equipment well-maintained and trained personnel should handle installations and repairs to minimize hazards and ensure system safety.

Can Temperature Fluctuations Affect Low Voltage Performance?

Yes, temperature fluctuations can influence your low voltage system’s performance. Temperature sensitivity impacts how components operate, causing potential voltage drops or malfunctions when thermal regulation isn’t maintained. You should monitor ambient temperatures and use proper insulation or cooling solutions to guarantee consistent output. By managing thermal conditions, you help prevent performance issues and extend the lifespan of your low voltage system.

What Role Does Circuit Layout Play in Voltage Consistency?

Your circuit layout plays a vital role in maintaining voltage consistency by minimizing issues like ground loops and power supply noise. Ensuring a proper, clean ground connection prevents ground loops that cause voltage fluctuations. Keeping power supply paths short and well-shielded reduces noise interference. By designing your layout carefully, you enhance low voltage stability, preventing fluctuations that could impact your equipment’s performance. Proper layout is key to reliable, consistent low voltage output.

Conclusion

By avoiding these common mistakes, you’ll keep your low voltage output flowing smoothly like a well-oiled machine. Think of your system as a delicate musical instrument—each part must be in harmony. Neglecting these tips can turn your setup into a discordant noise. Stay vigilant, tune regularly, and treat your equipment like a trusted partner. With care and attention, your voltage will sing in perfect tune, delivering reliable performance every time.