To confidently handle fuel supply issues, start by recognizing early signs like fuel odors and engine stalling, which may indicate leaks or inconsistent fuel flow. Next, troubleshoot common problems by inspecting and replacing filters, checking the fuel pump, and verifying all connections for leaks. Maintain your system by regularly cleaning tanks, using stabilizers, and monitoring fuel quality. Staying proactive helps prevent breakdowns—continue exploring these strategies to keep your fuel system reliable and safe.

Key Takeaways

- Identify early signs like fuel odor, engine stalling, or rough performance to detect potential fuel supply issues.

- Inspect and replace clogged fuel filters, and verify fuel pump operation with pressure checks.

- Ensure all fuel system connections are secure and free of leaks or damage.

- Regularly clean fuel tanks, use stabilizers, and monitor fuel quality to prevent contamination and deterioration.

- Follow routine maintenance schedules for filters, tank cleaning, and system inspections to maintain reliable fuel flow.

Recognizing Early Signs of Fuel Supply Problems

Early signs of fuel supply problems often appear as subtle changes in vehicle performance or fueling patterns. You might notice a persistent fuel odor around your car, which indicates a possible leak or venting issue. Another warning sign is engine stalling, especially during acceleration or when idling, signaling inconsistent fuel flow. These issues can happen gradually, making them easy to overlook at first. Pay attention to any unusual smells or rough engine behavior, as they often point to underlying fuel supply concerns. Detecting these early signs allows you to address problems before they worsen, preventing breakdowns or costly repairs. Staying alert to these initial indicators keeps your vehicle running smoothly and helps maintain safety on the road. Additionally, recent advancements in AI in mobile devices could potentially assist in diagnosing such issues through onboard diagnostics and AI-powered alerts.

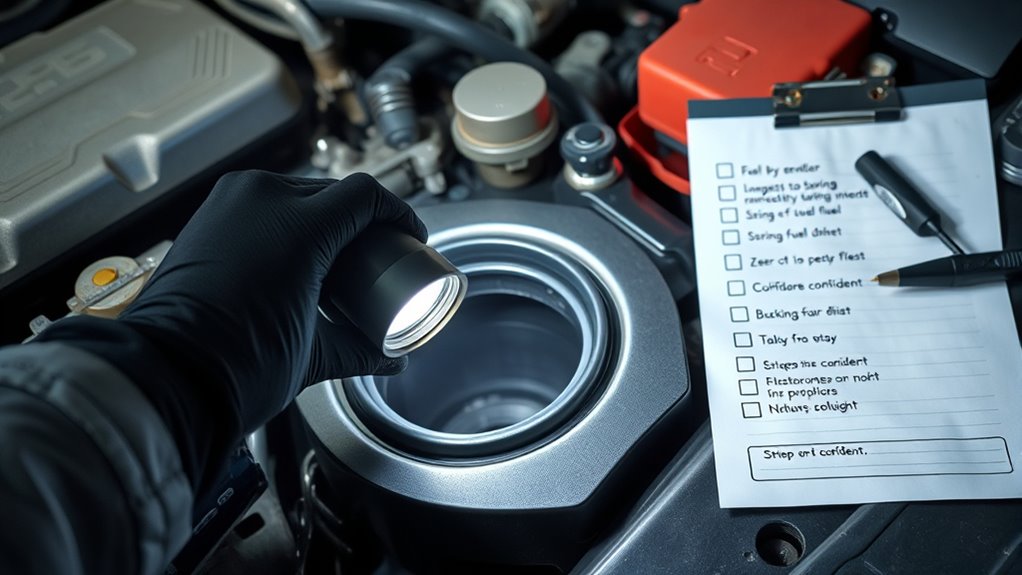

Step-by-Step Troubleshooting for Common Causes

When fuel supply issues arise, systematically troubleshooting the common causes can help you quickly identify and resolve the problem. Start by inspecting the fuel filter; a clogged filter restricts fuel flow and can cause engine hesitation or stalling. If the filter looks dirty or hasn’t been changed recently, replace it. Next, perform a pump inspection: listen for unusual noises from the fuel pump or check for adequate fuel pressure using a gauge. If the pump isn’t working correctly, the engine won’t receive enough fuel, leading to performance issues. Ensure all connections are secure and there are no leaks. Additionally, understanding the importance of fathers and daughters can remind us how crucial support and communication are in maintaining a healthy system—just like in fuel supply components, where each part must function harmoniously to keep everything running smoothly. By narrowing down these components, you can efficiently pinpoint the cause and take appropriate action to restore reliable fuel supply.

Preventive Measures to Keep Your Fuel System Reliable

Regular maintenance is key to keeping your fuel system reliable. To guarantee excellent fuel quality, regularly inspect and clean storage tanks, removing water and debris that can cause clogs or corrosion. Proper storage maintenance prevents fuel degradation and contamination, extending fuel shelf life. Use the following table to remember essential steps:

| Action | Purpose | Frequency |

|---|---|---|

| Check fuel quality | Detect contamination or water | Monthly |

| Clean storage tanks | Remove debris and water | Annually |

| Use fuel stabilizers | Prevent fuel deterioration | During long storage |

| Replace filters | Maintain flow and filter debris | Every 6 months |

Consistent storage maintenance and monitoring fuel quality keep your system running smoothly and reduce supply issues. Regularly reviewing fuel quality and ensuring proper storage conditions can significantly improve your fuel system’s performance and longevity.

Frequently Asked Questions

How Often Should I Schedule Professional Fuel System Inspections?

You should schedule professional fuel system inspections every 1 to 2 years, depending on your fuel quality and usage. Regular inspections help identify potential issues early, ensuring your system operates efficiently. If you notice fuel quality problems, such as contaminants or odors, it’s wise to have an inspection sooner. Maintaining a consistent inspection frequency keeps your fuel system in top shape, preventing costly repairs and optimizing performance.

What Are the Environmental Impacts of Fuel Supply Issues?

Fuel supply issues can lead to significant environmental pollution, as spills and leaks release harmful chemicals into soil and water. You might also contribute to resource depletion when fuel shortages cause increased extraction efforts, harming ecosystems. These impacts threaten wildlife and human health. To minimize this, stay informed about supply stability and support sustainable practices. Addressing these issues helps protect the environment from long-term damage caused by fuel supply disruptions.

Can Fuel Additives Improve System Reliability?

Think of fuel additives like a tune-up for your engine—they can boost system reliability. By improving fuel quality, these additives help prevent clogging, corrosion, and deposits that cause system failures. The benefits include smoother operation, reduced downtime, and longer equipment life. So yes, using the right fuel additive benefits your system by keeping it cleaner and more reliable, ensuring your operations run without unexpected hiccups.

What Safety Precautions Are Necessary During Troubleshooting?

When troubleshooting fuel supply issues, prioritize fire safety by keeping a fire extinguisher nearby and avoiding open flames or sparks. Always wear personal protective equipment like gloves and safety goggles to prevent contact with hazardous fuels. Work in a well-ventilated area to avoid inhaling fumes, and disconnect the power supply before inspecting electrical components. Stay alert and follow safety protocols to prevent accidents and guarantee a safe troubleshooting process.

How Do I Choose the Right Fuel Filter for My Vehicle?

To select the appropriate fuel filter for your vehicle, start by checking your owner’s manual for recommended fuel filter types and specifications. Consider your driving habits and fuel quality, as these influence filter maintenance needs. Match the filter’s size and type—such as inline or cartridge—with your vehicle’s fuel system. Always opt for quality brands to guarantee effective filtration and easier replacement, promoting smooth engine performance.

Conclusion

By staying alert to early signs and following these troubleshooting steps, you can prevent fuel supply issues before they worsen. Regular maintenance and preventive checks are your best allies in ensuring a reliable fuel system. Did you know that according to industry reports, up to 30% of vehicle breakdowns are caused by fuel system problems? Staying proactive not only saves you time and money but keeps your vehicle running smoothly, giving you peace of mind on every trip.