To troubleshoot battery chargers and keep-alive systems for generators, you must carefully calculate the right charging voltage and current based on your battery specs, ensuring proper matching to prevent damage. Monitor your battery capacity and state of charge regularly, and analyze your overall power consumption and load requirements. Evaluating system efficiency and connection quality helps identify issues early. Mastering these calculations can keep your system running smoothly—more expert tips are just ahead.

Key Takeaways

- Ensure charger voltage and current match battery specifications to prevent undercharging or overcharging.

- Calculate generator capacity based on peak load and charging requirements for reliable operation.

- Regularly monitor battery voltage, current, and electrolyte levels to maintain optimal capacity.

- Measure system efficiency and identify energy losses caused by wiring, connections, or environmental factors.

- Troubleshoot voltage drops by inspecting connectors, tightening connections, and cleaning corrosion to maintain proper power flow.

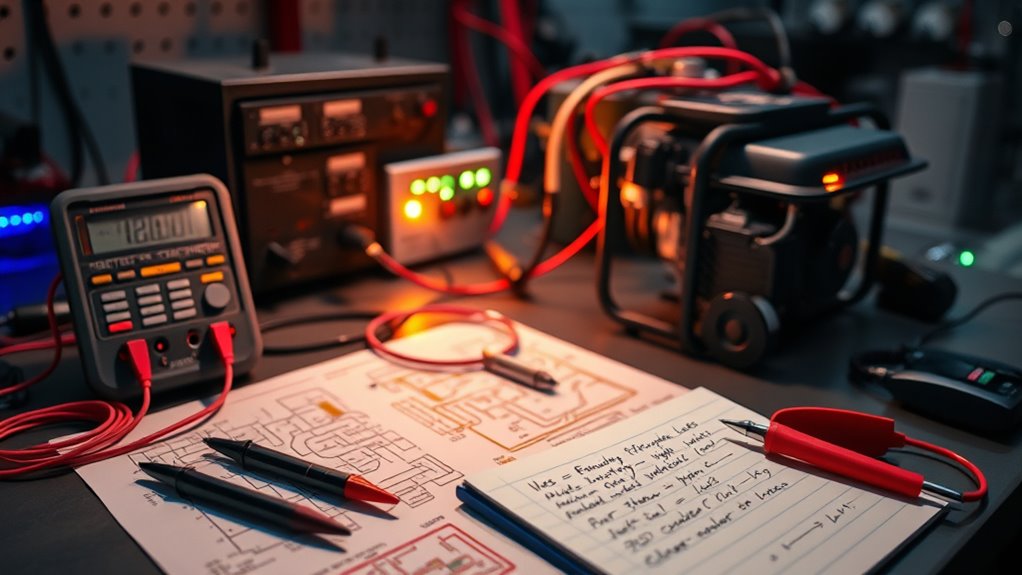

Calculating Correct Charging Voltage and Current

To guarantee your generator’s battery remains fully charged and reliable, you need to calculate the correct charging voltage and current. Start by understanding your solar panel’s output and how it matches your battery’s requirements. The solar panel’s voltage must be slightly higher than the battery’s voltage to ensure proper charging, but not so high that it causes damage. Inverter sizing also plays a role; it should be capable of handling the maximum current your charging system will draw. Use the battery’s specifications to determine the ideal voltage and current, then select a charger that can deliver these parameters safely. Proper calculations prevent undercharging or overcharging, extending your battery’s lifespan and maintaining reliable power for your generator. Additionally, considering the seasonal efficiency of your charging system can help optimize performance year-round.

Determining Battery Capacity and State of Charge

Understanding your battery’s capacity and current state of charge is fundamental for effective maintenance and reliable operation. As batteries age, their capacity diminishes, making it critical to regularly evaluate how much charge they hold. You can estimate capacity by measuring the battery’s voltage and current draw during discharges, considering age-related declines. Checking the electrolyte level is also essential; low levels can indicate aging or leaks, reducing overall capacity. Maintaining proper electrolyte levels helps preserve battery health and guarantees accurate state-of-charge readings. By monitoring these aspects, you’ll better understand when a battery needs replacement or maintenance, preventing unexpected failures. Regularly assessing capacity and state of charge allows you to optimize your generator’s performance and extend your battery’s lifespan.

Analyzing Power Consumption and Load Requirements

Accurately analyzing your generator’s power consumption and load requirements helps guarantee it can meet operational demands without overtaxing the system. To do this, list all connected devices and measure their power draw. Consider both continuous and peak loads, as these impact the generator’s capacity and your battery’s lifespan. Understanding total load helps you determine the appropriate charging cycles needed to maintain your batteries without shortening their life. Overloading can cause frequent deep discharges, reducing battery lifespan and increasing wear on your charger. Regularly reviewing your power consumption enables you to optimize load distribution and avoid unnecessary strain. Monitoring juice detox effects and consumption patterns can also provide insights into energy needs and efficiency. This proactive approach ensures your generator runs efficiently and your batteries stay healthy, maximizing both performance and longevity.

Evaluating System Efficiency and Losses

Evaluating your system’s efficiency and losses is essential for optimizing performance and extending equipment lifespan. When appraising efficiency, consider how well your generator and battery charger work together, especially if you’re integrating solar power. Solar integration can reduce fuel consumption but may introduce variability due to environmental factors like shading, temperature, or weather. These factors can cause energy losses in the system, such as increased resistance or reduced charging efficiency. To accurately evaluate, measure input and output power at various loads and conditions, and compare expected versus actual performance. Identifying sources of inefficiency allows you to optimize component placement, improve insulation, or select better materials, ultimately ensuring your system runs at peak efficiency with minimal losses. Incorporating performance testing can help you identify hidden inefficiencies and improve overall system reliability.

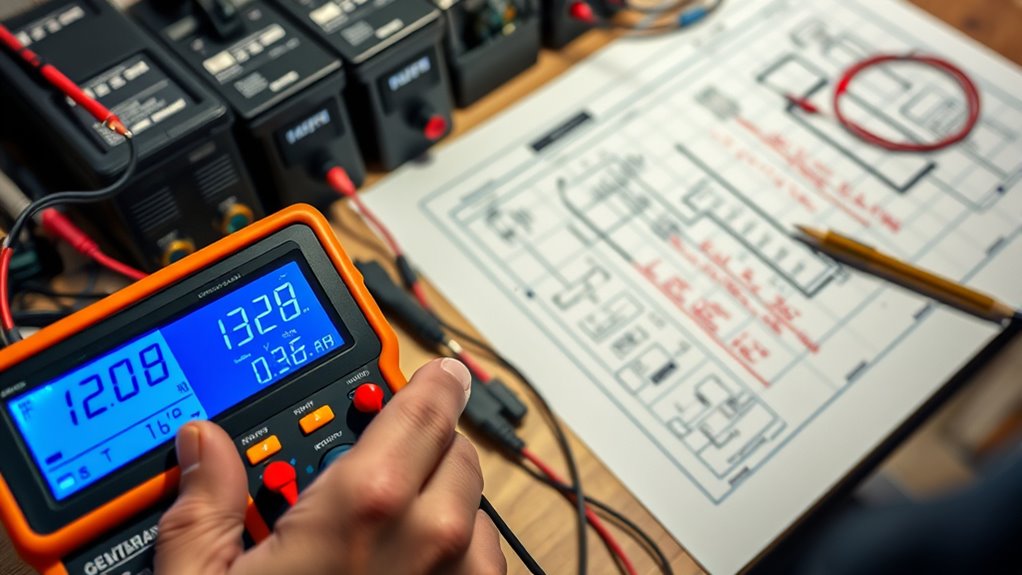

Troubleshooting Voltage Drops and Connection Issues

When troubleshooting your generator and battery charger system, voltage drops and connection issues often point to underlying problems that hinder performance. Start by inspecting connectors for corrosion, which can cause increased resistance and voltage loss. Corrosion prevention is key; clean and apply protective coatings to connectors regularly. Check all wiring connections for looseness or damage, ensuring they’re secure and free of corrosion. Use a multimeter to measure voltage at different points; significant drops indicate poor contact or corroded connections. Tighten or replace faulty connectors as needed. Proper connector inspection helps identify issues early, preventing voltage drops that compromise system reliability. Maintaining clean, corrosion-free connections ensures efficient power flow and prolongs your generator’s lifespan. Additionally, ensuring proper airflow around components can prevent overheating and maintain optimal operation.

Frequently Asked Questions

How Often Should Battery Chargers Be Maintained for Optimal Performance?

You should check and maintain your battery chargers regularly, ideally every 3 to 6 months. Adhering to proper charging schedules and maintenance intervals guarantees peak performance and longevity. During these intervals, inspect for corrosion, clean terminals, and verify charging output. Consistent maintenance prevents issues like reduced efficiency or failure, keeping your generator reliable. Adjust the frequency based on usage and environmental conditions to assure your battery chargers stay in top condition.

What Are the Signs of a Failing Battery Charger or Keep-Alive System?

Like a vintage radio needing fine-tuning, your system shows signs of a failing battery charger or keep-alive. Watch for battery degradation, which causes reduced runtime, and charging inconsistency, leading to sudden power loss. If your generator’s voltage fluctuates or batteries won’t hold a charge, it’s time to inspect the charger or keep-alive system. Ignoring these signs can result in costly breakdowns, so stay vigilant and act promptly.

Can Environmental Factors Affect the Charging Calculations and System Efficiency?

Environmental influences can definitely affect your charging calculations and system efficiency. Factors like temperature, humidity, and altitude impact how well your charger performs, often reducing charge efficiency. Hot or cold conditions can cause batteries to charge slower or faster than expected, leading to inaccurate calculations. To guarantee peak performance, monitor environmental factors regularly and adjust your charging parameters accordingly, preventing system failures and extending your generator’s lifespan.

How Do Temperature Variations Impact Battery Capacity and Charge Accuracy?

Temperature variations substantially impact your battery capacity and charge accuracy through thermal effects. When it’s hot, thermal effects reduce capacity and can cause voltage instability, leading to inaccurate charge readings. Conversely, cold temperatures decrease chemical activity, lowering capacity and making voltage less stable. To guarantee accurate charging, you must account for these thermal effects by adjusting your system for temperature fluctuations, maintaining voltage stability, and preventing overcharging or undercharging.

What Safety Precautions Are Essential During Troubleshooting and Calculations?

Are you prepared to handle electrical hazards safely? You must prioritize electrical safety by always wearing personal protective equipment, like insulated gloves and eye protection, during troubleshooting and calculations. Confirm the power is disconnected before working on batteries or chargers, and double-check for residual voltage. Following these precautions minimizes risks of shocks, burns, or short circuits. Don’t take shortcuts—your safety depends on careful adherence to these essential safety practices.

Conclusion

Now, picture your generator humming steadily, its battery happily charged, and all connections glowing with reliable energy. By mastering these calculations, you keep the flow of power smooth as a river, preventing drops and disruptions. Think of troubleshooting as tuning a musical instrument—every detail matters. With careful attention, you guarantee your system runs seamlessly, like a well-oiled machine, ready to power your world without a hitch. Keep these steps in mind, and let your generator shine bright.