Understanding advanced natural gas line sizing means knowing how to balance flow velocity, pipe diameter, and pressure drop to ensure safety and efficiency. Proper sizing prevents pressure loss, reduces noise, and minimizes energy waste, while choosing the right materials can boost durability. Accurate load calculations and avoiding common mistakes like undersizing or poor installation are key. If you keep exploring, you’ll uncover proven tips to optimize your gas system and prevent costly issues.

Key Takeaways

- Proper pipe sizing balances flow velocity and pressure drop to prevent inefficiencies and ensure safety.

- Calculating accurate pressure drops considering pipe length, diameter, and load optimizes system performance.

- Selecting the right material and diameter reduces corrosion risks and maintains consistent gas flow.

- Insulating pipes minimizes heat loss and prevents condensation, safeguarding system reliability.

- Avoid common mistakes like underestimating demand or neglecting safety margins for long-term efficiency.

Understanding Gas Flow Dynamics and Pipe Sizing

Understanding gas flow dynamics is essential when determining the appropriate pipe size for natural gas lines. Your goal is to guarantee optimal flow velocity—too high, and you risk pressure loss and noise; too low, and flow efficiency drops. Proper pipe sizing balances these factors by matching flow velocity to system requirements. Additionally, pipe insulation plays a critical role in maintaining consistent gas temperature, which affects flow characteristics. Insulated pipes reduce heat loss, preventing temperature drops that could cause condensation or pressure issues. By understanding how flow velocity interacts with insulation, you can select a pipe size that minimizes energy losses and maintains steady flow. Recognizing the importance of soulmate angel numbers can also provide insight into timing and readiness for love, much like how understanding flow dynamics helps optimize system performance. This foundational knowledge helps you design a system that’s both safe and efficient, avoiding future problems caused by improper sizing.

Calculating Pressure Drop and Its Impact on System Performance

Calculating pressure drop is crucial because it directly affects the efficiency and safety of your natural gas system. When pressure loss occurs along the pipe, it reduces flow efficiency, meaning less gas reaches your appliances or equipment, which can compromise performance. Understanding how to accurately determine pressure drop helps you identify potential bottlenecks and ensures your system maintains adequate pressure throughout. If pressure loss is too high, it can lead to inefficient combustion, increased fuel consumption, or even unsafe conditions. By factoring in pipe length, diameter, and flow rate, you can predict pressure loss accurately. This knowledge allows you to optimize your line size and layout, minimizing pressure drop while maximizing flow efficiency and system reliability. Additionally, considering the flow rate and system demands is essential for selecting the appropriate pipe dimensions and ensuring consistent performance.

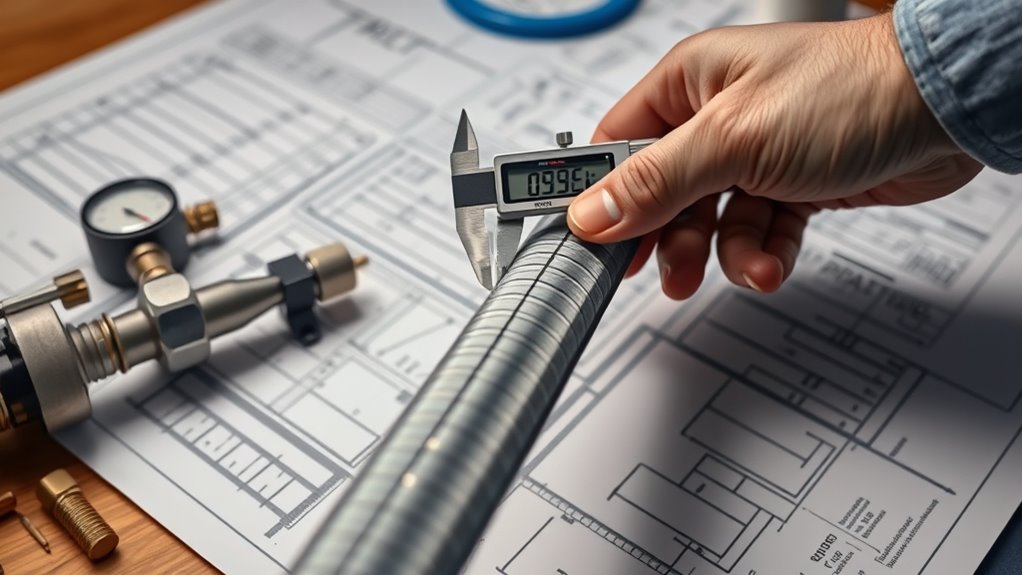

Selecting the Correct Pipe Material and Diameter for Safety and Efficiency

Choosing the right pipe material and diameter is essential for ensuring your natural gas system operates safely and efficiently. You need materials with good corrosion resistance to prevent leaks and deterioration over time, especially if exposed to moisture or soil. Steel, copper, and plastic pipes each have benefits; steel offers durability, but may require protective coatings. Proper installation techniques are equally important—use correct fittings, secure connections, and avoid sharp bends that can restrict flow. Selecting an appropriate diameter ensures ideal flow rates and minimizes pressure drops, reducing risk and improving efficiency. Additionally, understanding flow dynamics helps in designing a system that maintains consistent pressure throughout. Remember, the right combination of material and diameter not only enhances safety but also extends the lifespan of your system, saving you time and money on maintenance and repairs.

The Role of Flow Rate and Load Calculations in System Design

Have you ever wondered how to determine the right pipe size and system capacity for your natural gas setup? Flow rate and load calculations are essential for this. They help you estimate how much gas your system needs to deliver safely and efficiently, considering gas pressure and safety regulations. Proper calculations ensure your system can handle peak demand without risking pressure drops or unsafe conditions. Incorporating industry trends into your planning can help you stay ahead of regulatory changes and technological advancements.

You should focus on:

- Calculating maximum load demands to prevent undersizing

- Adjusting for gas pressure variations in your calculations

- Ensuring compliance with safety regulations

- Verifying system capacity aligns with future expansion plans

Accurate flow rate and load calculations are vital for ideal system design, safety, and long-term performance. They form the backbone of a reliable, code-compliant natural gas distribution system.

Common Mistakes in Gas Line Sizing and How to Avoid Them

Many common mistakes in gas line sizing stem from overlooking key factors like pressure drops, peak demand, or safety regulations, which can compromise system performance and safety. One frequent error is ignoring proper installation procedures, leading to installation errors that affect flow and safety. Another mistake is neglecting code compliance, risking violations that can cause costly repairs or shutdowns. To avoid these issues, always follow established guidelines and double-check your calculations. Make certain your installation is performed by qualified professionals familiar with the latest codes. Properly sizing your gas line means considering all demand points and safety margins. Additionally, understanding proper pipe material selection can significantly impact the durability and safety of the system. By paying attention to these details, you can prevent costly mistakes, maintain system efficiency, and ensure safety for all users.

Frequently Asked Questions

How Does Altitude Affect Natural Gas Line Sizing?

Altitude effects your natural gas line sizing because higher elevations reduce gas pressure, which impacts flow capacity. You need to account for decreased gas pressure at altitude to guarantee proper sizing; otherwise, your system might not deliver enough gas. By adjusting for altitude effects, you maintain ideal gas pressure and flow, preventing issues like insufficient power or safety concerns. Properly considering altitude effects ensures your gas line performs reliably at any elevation.

What Are the Latest Industry Standards for Gas Pipe Installation?

You should follow the latest industry standards for gas pipe installation by adhering to safety regulations like the National Fuel Gas Code (NFPA 54) and local codes. Make certain proper pipe insulation to prevent temperature fluctuations and condensation. Regularly check for updates from organizations like the American Gas Association. Proper installation and safety compliance protect your property and ensure efficient, safe natural gas delivery.

How Can I Detect and Prevent Gas Line Leaks Effectively?

To detect and prevent gas line leaks effectively, you should perform regular leak detection using soapy water or electronic detectors to spot leaks early. Conduct preventive maintenance by inspecting fittings, joints, and pipelines frequently, ensuring no corrosion or damage occurs. Always monitor for the smell of gas or unusual hissing sounds, and act swiftly if you suspect a leak to keep your property safe.

What Are the Environmental Considerations in Gas Line Material Selection?

When choosing gas line materials, you should prioritize eco-friendly options that minimize environmental impact. Opt for materials that promote emission reduction, such as corrosion-resistant plastics or composites, which prevent leaks and reduce harmful emissions. Consider the long-term sustainability of your choices, ensuring they’re durable and recyclable. This approach not only protects the environment but also enhances safety and efficiency in your gas distribution system.

How Do Future System Expansions Influence Initial Pipe Sizing Decisions?

When planning initial pipe sizing, you need to take into account future system capacity and expansion planning. Oversizing your pipes now allows for easier, cost-effective system expansions later, reducing the need for costly retrofits. By designing with growth in mind, you ensure your gas line can handle increased demand without compromising safety or efficiency. This proactive approach saves money and minimizes disruptions as your system evolves.

Conclusion

Now that you understand the fundamentals of gas line sizing, you might think it’s too complex or time-consuming. But with proper knowledge, you’ll save money, ensure safety, and improve system performance. Don’t let fear of mistakes hold you back—trust your calculations and choose the right materials. The effort pays off with a reliable, efficient gas system that meets your needs and keeps everyone safe. You’ve got this!