Many believe generators last forever, but lifespan depends on factors like maintenance, usage, and material quality. Regular upkeep and managing load can extend their life, while neglect shortens it. Signs like increased noise or poor performance indicate it might be time to replace or upgrade. Instead of relying solely on age, focus on your generator’s condition. To learn how to effectively optimize its longevity and avoid premature replacement, keep exploring this topic.

Key Takeaways

- Generator lifespan depends on type, quality, environment, and maintenance, not just age alone.

- Regular upkeep and inspections can significantly extend a generator’s usable life.

- Signs like declining efficiency or frequent breakdowns are better indicators for replacement than age.

- High-quality materials and proper construction resist wear, delaying the need for replacement.

- Upgrading to newer energy sources or improving maintenance practices can optimize performance and lifespan.

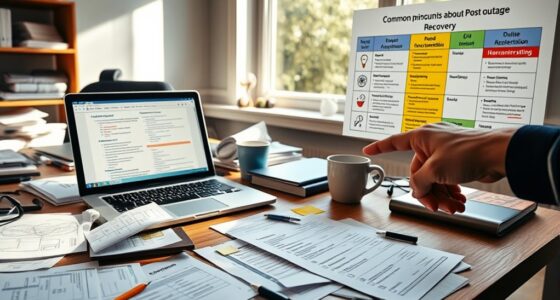

Common Myths About Generator Lifespan

Many people believe that a generator will last forever if it’s well-maintained, but that’s a common misconception. No matter how carefully you care for it, generators have a finite lifespan due to wear and tear. Some assume that improving fuel efficiency alone extends its life, but efficiency doesn’t guarantee durability. Instead, focusing on quality components and proper operation is key. Additionally, many think noise levels aren’t a concern for longevity, but high noise often indicates underlying problems that could shorten your generator’s life. While regular maintenance helps, it won’t prevent all deterioration. Recognizing that even well-maintained generators have limits helps you plan for replacements and avoid unexpected failures. Additionally, understanding the vetted safety standards for newborn products emphasizes the importance of choosing reliable, tested equipment to ensure longevity and safety. Understanding these myths ensures you make informed decisions about your generator’s longevity.

How Maintenance Impacts Your Generator’s Longevity

While regular maintenance can’t stop a generator’s inevitable wear, it plays a vital role in extending its operational life. Proper upkeep ensures maximum fuel efficiency, reduces breakdowns, and minimizes environmental impact. When you stay on top of routine checks, your generator runs smoother and more reliably, saving you money and energy in the long run. Neglecting maintenance can lead to inefficient fuel consumption, increased emissions, and costly repairs that shorten its lifespan. By investing time in maintenance, you help preserve your generator’s performance, delay replacement needs, and protect the environment. Additionally, understanding the importance of sound design techniques can aid in diagnosing issues and optimizing your generator’s operation.

Signs Your Generator Might Be Nearing Replacement

Recognizing when your generator is nearing the end of its useful life is essential to avoiding unexpected failures. You might notice a drop in fuel efficiency, meaning it consumes more fuel for the same power output. Additionally, increased noise levels can indicate internal wear or component issues. Other signs include frequent breakdowns, difficulty starting, or uneven power delivery. These symptoms suggest it’s time to contemplate replacement before a costly failure occurs. Keep an eye on the following:

| Signs of Nearing Replacement | What It Means |

|---|---|

| Decreased fuel efficiency | Worn components reduce performance |

| Elevated noise levels | Mechanical issues developing |

| Inconsistent power output | Internal damage or aging parts |

| Frequent breakdowns | Major repairs needed |

Addressing these signs early can save you money and ensure reliable power. Proper maintenance and understanding the generator lifespan can help you plan for timely replacement and avoid unexpected outages.

The Role of Usage Frequency and Load in Wear and Tear

The more you use your generator, the faster it wears out. Heavy loads put extra stress on its components, causing quicker deterioration. Keeping an eye on both usage frequency and load can help you better predict when it’s time for a replacement. Additionally, proper maintenance and tuning of connected systems, similar to Mazda Tuning practices, can extend your generator’s lifespan.

Frequent Use Accelerates Deterioration

Frequent use and higher load demands cause generators to wear out more quickly. When you run your generator often or push it to handle heavy loads, components experience increased stress, leading to faster deterioration. This can impact fuel efficiency, making each gallon stretch less, and cause noise levels to rise as parts strain under pressure. The more you rely on your generator, the sooner its parts will weaken or fail. Additionally, high-performance components are more susceptible to accelerated wear when pushed beyond their optimal operating conditions.

Heavy Loads Increase Stress

Pushing your generator to handle heavy loads amplifies the stress on its components, speeding up wear and tear. When you consistently operate near or above the load capacity, you increase stress factors that strain parts like the engine, alternator, and cooling system. This added pressure causes components to work harder, generating more heat and friction, which accelerates deterioration. Overloading also reduces the overall lifespan of your generator by stressing critical parts beyond their designed limits. It is crucial to monitor load levels carefully, ensuring you don’t regularly push your generator past its recommended capacity. By managing usage and avoiding excessive loads, you help minimize stress factors, prolonging its functional life and maintaining reliable performance over time. Load management strategies are essential for preserving your generator’s longevity and ensuring it performs when you need it most.

Material Quality and Build: What Really Affects Durability

Material quality and construction play a crucial role in determining a generator’s durability. The best generator material guarantees components withstand wear and environmental stress, while construction quality ensures everything fits and functions correctly. When you choose a generator with high-quality materials and solid construction, you’re investing in longevity and reliability. Poor-quality materials and shoddy build can lead to frequent breakdowns, costly repairs, and shortened lifespan. Additionally, material resilience ensures your generator can handle diverse conditions without deteriorating prematurely. Consider these factors:

- Resilient generator material that resists corrosion and fatigue

- Precision in construction for peak performance

- Sturdy casing that protects internal parts

- Robust wiring and connectors for safety and efficiency

- High-quality components that reduce maintenance needs

Focusing on these elements means your generator will stand the test of time, saving you money and stress.

The Importance of Regular Inspections and Servicing

Why are regular inspections and servicing essential for your generator’s performance? They help maintain ideal fuel efficiency by catching issues like clogged filters or fuel system problems early. When your generator is well-maintained, it consumes less fuel, saving you money over time. Regular servicing also keeps noise levels down, preventing parts from becoming loose or worn that could cause loud vibrations or rattling. Inspections ensure crucial components are functioning correctly, reducing the risk of unexpected breakdowns. Addressing minor problems during routine checks extends your generator’s lifespan and keeps it running smoothly. Additionally, following proper maintenance routines based on manufacturer guidelines can prevent costly repairs and ensure consistent operation. Ultimately, consistent inspections and servicing preserve your generator’s reliability, efficiency, and quiet operation, ensuring it’s ready whenever you need it most.

Average Lifespan of Different Generator Types

The average lifespan of a generator varies markedly depending on its type and usage, but understanding these differences can help you plan for maintenance and eventual replacement. Portable generators often last around 10,000 hours if well-maintained, while standby units can reach 20-30 years with proper care. Inverter generators tend to have longer fuel efficiency and quieter noise levels, contributing to extended service life. Heavy-duty industrial models might last 15-20 years but require regular servicing to prevent breakdowns. Keep in mind that environmental conditions and operating frequency heavily influence longevity. Recognizing these factors helps you avoid unexpected failures and costly repairs, ensuring your investment lasts. Being aware of each generator type’s lifespan empowers you to schedule timely upgrades and maintain ideal performance. Generator FAQs provide additional insights into maintenance and replacement considerations.

When to Consider Upgrading or Replacing Your Generator

Knowing when to upgrade or replace your generator is essential to maintaining reliable power and avoiding costly breakdowns. If your generator frequently requires repairs or struggles to meet your energy needs, it’s time to contemplate an upgrade. Advances in alternative energy, like solar power, offer cleaner, more efficient options that can supplement or replace traditional generators. When your existing unit nears or exceeds its expected lifespan without reliable performance, it’s a sign to replace it. Upgrading can also be driven by changing power demands or a desire for greater efficiency. If you’re exploring sustainable options, integrating solar power systems with your generator setup can improve reliability and reduce long-term costs. Recognizing these signs ensures you stay prepared and avoid unexpected outages. Additionally, understanding your generator’s personality traits can help in selecting the most suitable model for your needs.

Cost-Effective Practices to Extend Your Generator’s Life

Proper maintenance and smart practices can substantially extend your generator’s lifespan without the need for costly replacements. By focusing on fuel efficiency and noise reduction, you guarantee ideal performance and longevity. Regularly check and replace filters to keep fuel consumption low and prevent strain on the engine. Keep your generator clean and well-lubricated to minimize noise and mechanical wear. Use quality fuel and store it properly to maximize efficiency. Schedule routine inspections to catch issues early before they escalate. These simple steps can save you money, reduce downtime, and make your generator more reliable over time.

- Prioritize regular tune-ups for peak fuel efficiency

- Install sound-dampening enclosures to cut noise

- Use high-quality fuel to prevent engine strain

- Keep vents and cooling systems clear for better airflow

- Monitor and adjust load to avoid unnecessary wear

Debunking Strict Replacement Timelines

You shouldn’t rely solely on age to decide when to replace your generator; how you use and maintain it matters more. Proper upkeep can markedly extend its lifespan, regardless of its years. Let’s explore why strict timelines aren’t the only factor in replacement decisions.

Age Isn’t Sole Indicator

While age can suggest a generator’s potential lifespan, it shouldn’t be the sole factor in determining whether to replace it. A generator’s condition depends more on its battery capacity, fuel efficiency, and overall performance. Don’t assume it’s time for a new one just because it’s old—signs like decreased power output or increased fuel consumption matter more. Regular maintenance can extend its life and keep it running smoothly. Remember, a well-maintained generator with good battery capacity can outperform a newer but neglected unit. Avoid unnecessary replacements that drain your budget. Instead, focus on real indicators of wear and tear.

- You could be throwing away a reliable generator that still has plenty of life left.

- Poor fuel efficiency could be a sign your generator needs repair, not replacement.

- Diminished battery capacity impacts performance more than age.

- Neglecting maintenance shortens lifespan regardless of age.

- Longevity depends on care, not just the calendar.

Usage Matters Most

Age alone doesn’t determine when a generator needs replacing; instead, how much you use it and how well you maintain it play bigger roles. Frequent use can wear components faster, impacting fuel efficiency and noise levels over time. If your generator runs regularly, it may need attention sooner, regardless of age. Conversely, infrequent use can prolong its life, even if it’s older. Pay attention to signs like declining fuel efficiency or increased noise levels, which indicate wear. These factors matter more than strict timelines. Regularly monitoring your generator’s performance helps you catch issues early, saving you money and avoiding unexpected breakdowns. Remember, a well-maintained generator that’s used often may need replacement sooner than a seldom-used one, regardless of age.

Maintenance Extends Life

Regular maintenance can substantially extend your generator’s lifespan and challenge the idea of strict replacement timelines. Proper upkeep keeps your generator running efficiently, improving fuel efficiency and reducing environmental impact. When you prioritize regular checks and timely repairs, you avoid unnecessary breakdowns and costly replacements. Maintenance ensures your generator remains reliable during critical moments, giving you peace of mind. It also helps you get the most out of your investment, delaying the need for premature replacement.

- Feel confident knowing your power source is dependable when you need it most

- Save money by avoiding costly emergency repairs and early replacements

- Reduce your carbon footprint with a more efficient, eco-friendly generator

- Experience the satisfaction of maintaining a responsible, sustainable energy solution

- Preserve your generator’s performance and longevity through consistent care

Frequently Asked Questions

How Do Environmental Factors Influence Generator Lifespan?

Environmental factors considerably influence your generator’s lifespan. Exposure to harsh elements like moisture, extreme temperatures, or dust can cause corrosion and wear. You should increase maintenance frequency if your generator faces tough environmental exposure, ensuring it stays in good condition. Protect your generator with proper enclosures and regular inspections to prevent damage, extending its life and keeping it reliable when you need it most.

Can Generator Size Affect Its Durability Over Time?

Imagine a small portable generator used regularly during camping trips. Its size impacts durability factors—smaller units often face more wear and tear from frequent use and limited cooling. Larger generators tend to have better durability over time because their size allows for enhanced cooling and robust components. So, generator size does affect durability, as bigger units typically withstand prolonged use better, but proper maintenance remains essential regardless of size.

Are There Specific Brands Known for Longer-Lasting Generators?

Some brands are known for longer-lasting generators, thanks to solid reputation and warranty coverage, which shows their confidence in durability. Brands like Honda, Generac, and Briggs & Stratton often stand out because of their reliable performance and good customer support. You should choose a brand with a strong reputation and extensive warranty, as these factors indicate longer lifespan and better after-sales service, ultimately helping your generator last longer.

What Role Does Fuel Quality Play in Generator Longevity?

Fuel quality critically impacts your generator’s longevity. If you use contaminated fuel, it can cause buildup and damage engine parts. Adding fuel additives helps prevent corrosion, stabilize fuel, and keep contaminants at bay. Always use clean, high-quality fuel and incorporate appropriate additives to guarantee smoother operation and extend your generator’s lifespan. Regularly checking and maintaining fuel quality is a simple but effective way to keep your generator running longer.

How Does Operating Temperature Impact Generator Wear and Tear?

Operating temperature greatly impacts your generator’s wear and tear. If it runs too hot, thermal stress can damage components and reduce lifespan. Proper cooling systems help maintain ideal temperatures, preventing overheating and minimizing wear. Regular maintenance ensures your cooling system functions well, so your generator stays within safe temperature ranges. By managing temperature effectively, you extend your generator’s reliability, reduce repairs, and maximize its operational lifespan.

Conclusion

Remember, your generator’s lifespan isn’t set in stone—it’s shaped by your maintenance habits, usage, and how well you care for it. Don’t fall for myths or rush to replace it prematurely; instead, stay vigilant with regular checks and proper upkeep. With the right care, you could extend its life beyond what you’d ever imagine, turning your generator into a reliable powerhouse that outlasts even the wildest expectations.