Ensuring your natural gas line is properly sized is key to safety, efficiency, and code compliance. You need to consider factors like gas demand, pipe material, distance, and pressure loss. Following national standards like NFPA 54 and local regulations helps prevent leaks, pressure drops, and other hazards. Proper installation practices and documentation are crucial for safety and inspections. Keep exploring this guide to learn the essential steps for compliant, safe gas line sizing and installation.

Key Takeaways

- Understand and adhere to national (NFPA 54) and local codes for gas line sizing and safety compliance.

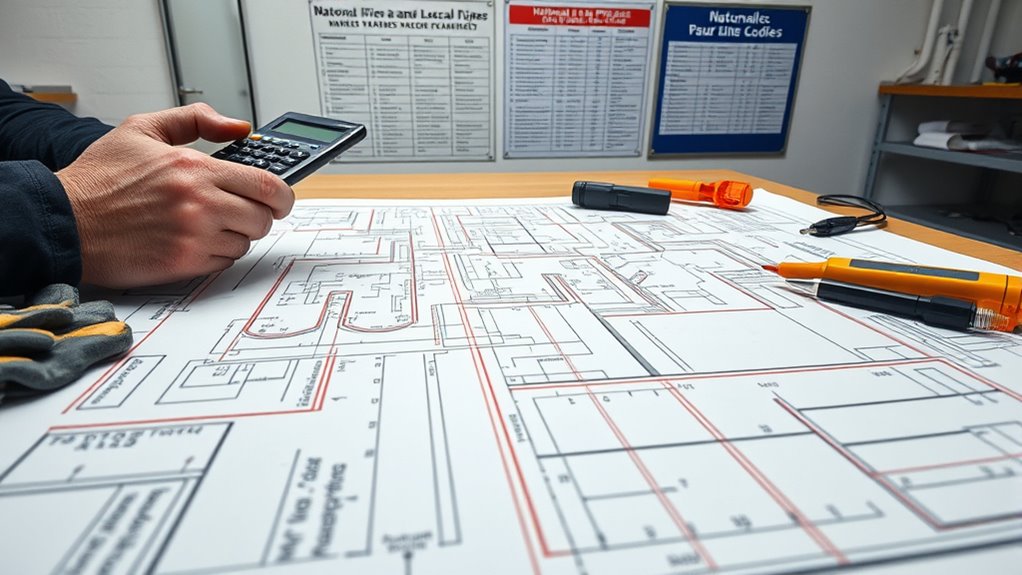

- Use proper calculation methods and tools to determine pipe sizes based on gas flow, pressure, and distance.

- Verify material compatibility, pressure ratings, and installation practices to prevent leaks and ensure safety.

- Obtain necessary permits, maintain documentation, and conduct inspections to demonstrate code compliance.

- Follow best practices, including proper valve placement, leak testing, and adherence to safety regulations during installation.

Understanding the Importance of Proper Gas Line Sizing

Proper gas line sizing is essential to guarantee safety, efficiency, and reliable operation of your gas systems. When lines are too small, pressure drops can occur, leading to incomplete combustion and potential gas leaks. Proper sizing helps prevent gas leak prevention issues by maintaining appropriate flow rates and pressure. It also ensures that your emergency shutoff systems function correctly during a crisis, reducing hazards and minimizing damage. Incorrectly sized lines increase the risk of dangerous leaks or system failure, which could result in serious safety concerns. By following proper sizing practices, you enhance overall safety, protect your property, and ensure compliance with codes. Understanding the correct sizing standards is crucial for achieving these safety and performance goals. Ultimately, correct gas line sizing is a critical step in safeguarding everyone around your gas system and enabling quick, effective responses when needed.

Key Factors Influencing Gas Line Size

Your gas line size depends on several key factors you need to consider carefully. These include the flow rate of gas required, the material of the pipe, and the distance and elevation from the source to the point of use. Understanding how these elements interact helps guarantee safe, efficient gas delivery. Additionally, adherence to vegetable juices and other nutrient-rich options can support overall health and proper functioning of your body’s systems.

Gas Flow Rate

What determines the appropriate gas line size? The key factor is the gas flow rate needed to supply your appliances efficiently. When flow rates are high, you’ll need a larger pipe to prevent flow restrictions that can reduce performance or cause pressure drops. Gas pressure also plays a critical role; if pressure drops too much along the line, it can limit flow and cause operational issues. To guarantee your system works safely and effectively, you must calculate the required flow rate accurately, considering appliance demand and potential future expansion. Selecting a line size that accommodates maximum flow without excessive pressure drops helps maintain consistent gas pressure and excellent performance. Proper sizing minimizes flow restrictions, ensuring safe, reliable gas delivery. Additionally, understanding pressure regulation and selecting appropriate components can further enhance system safety and efficiency.

Pipe Material Choice

Choosing the right pipe material is essential because different materials have varying flow capacities and pressure loss characteristics that directly impact line size. You need to contemplate corrosion resistance since some materials withstand environmental factors better, reducing maintenance and safety risks. For example, steel pipes are strong but prone to corrosion without proper coating, while plastic pipes offer excellent corrosion resistance and a lower environmental impact. Your choice influences the overall durability, safety, and efficiency of your gas line. Additionally, selecting eco-friendly materials can minimize environmental impact during installation and disposal. Understanding how each material affects flow and pressure loss helps ensure you select the ideal pipe for your specific needs, complying with code requirements while maintaining safety and performance standards. Properly assessing precious metals dealer reviews can also inform your investment decisions related to your project’s financial planning.

Distance and Elevation

Distance and elevation considerably influence gas line sizing because both affect the pressure and flow rate throughout the system. Longer distances increase pressure drops, requiring you to size the pipe accordingly to maintain adequate flow. Elevated terrain can cause pressure loss or gain, impacting pipeline safety and leak detection efforts. When planning your gas line, account for these factors to prevent under-sizing, which risks pressure drops, or over-sizing, which can be unnecessarily costly. Properly addressing distance and elevation ensures the system functions efficiently while maintaining safety standards. Monitoring pressure changes related to elevation helps improve leak detection, reducing potential hazards. Additionally, understanding the horsepower of the gas line system can aid in selecting appropriate components to ensure optimal performance. Ultimately, understanding these factors helps you design a reliable, compliant gas line that prioritizes safety and ideal performance.

Overview of Relevant National and Local Codes

Understanding which codes apply to your project is essential for proper gas line sizing. You need to be aware of both national standards and any local code variations that may impact your work. Ensuring compliance documentation is in order helps you meet all requirements and avoid potential issues. Being familiar with industry trends can also assist in staying current with evolving regulations.

Applicable Codes Overview

To guarantee safe and compliant natural gas line installations, it’s essential to familiarize yourself with the relevant codes that govern the design and construction process. These codes ensure gas safety and proper code enforcement, minimizing risks. National standards like the NFPA 54 (National Fuel Gas Code) set the baseline, while local codes adapt these guidelines to regional conditions. Understanding both is vital for compliance. Here’s a quick overview:

| National Codes | Local Codes |

|---|---|

| NFPA 54 (National Fuel Gas Code) | City or state-specific amendments |

| International Mechanical Code (IMC) | Local permitting requirements |

| ANSI standards | Regional safety regulations |

| OSHA guidelines | Local inspection protocols |

| Local building codes | Community-specific safety rules |

Additionally, recognizing Narcissistic traits in professional or personal interactions can help prevent manipulative behaviors that might compromise safety or compliance procedures.

Local Code Variations

While national standards like NFPA 54 provide a solid foundation for natural gas line installations, local codes often introduce specific variations that must be followed. These regional regulations can differ based on city, county, or state requirements, affecting pipe sizing, allowable materials, and safety procedures. It’s essential to check local codes before starting work, as they may impose stricter standards than national ones. Additionally, local laws often specify contractor licensing requirements, ensuring only qualified professionals perform gas line work. Failing to adhere to these regional regulations can lead to fines, safety hazards, or failed inspections. To ensure compliance and safety, always verify local code variations and confirm your contractor’s licensing before proceeding with any natural gas line installation or modification. Moreover, understanding essential oil applications can enhance safety and wellbeing in related maintenance or troubleshooting tasks.

Compliance Documentation

Compliance documentation for natural gas line installation involves verifying that your project meets both national and local codes. This ensures pipeline safety and effective leak detection, preventing hazards. Proper documentation includes permits, inspection reports, and adherence to standards. Without it, you risk delays, fines, or unsafe installations. To stay compliant, consider these key points:

- Confirm your project follows the National Fuel Gas Code and local regulations.

- Obtain necessary permits before starting work.

- Keep detailed records of inspections and testing results.

- Ensure documentation demonstrates compliance with pipeline safety and leak detection requirements.

Staying diligent with compliance documentation helps you avoid costly mistakes, ensures safety, and confirms your project meets all legal standards.

Calculating Gas Line Diameter: Tools and Techniques

Calculating the correct gas line diameter is essential for guaranteeing safety, efficiency, and code compliance. To do this accurately, you’ll need to use specific tools and techniques. One common method involves utilizing flow rate calculators or software that considers pressure loss, pipe length, and gas demand. These tools help you determine the ideal diameter to prevent gas leaks and maintain proper flow. When planning your gas line, remember that pipe insulation can influence overall safety and efficiency, especially in colder environments. Proper sizing also aids in effective gas leak detection, making it easier to identify issues early. Additionally, understanding gas flow dynamics can enhance your ability to select the right pipe dimensions and optimize system performance. By applying these tools and techniques carefully, you ensure your gas system operates safely and adheres to all relevant codes.

Material Options and Compatibility for Gas Piping

Choosing the right material for gas piping is vital to guarantee safety, durability, and compatibility with the type of gas used. Your selection impacts pipe corrosion resistance and ensures material compatibility with natural gas. Consider these options:

- Steel – Strong and reliable, but prone to pipe corrosion if not properly coated.

- Copper – Excellent corrosion resistance and compatibility with natural gas, but more expensive.

- Plastic (PEX or PE) – Lightweight and corrosion-resistant, suitable for certain installations.

- Galvanized Steel – Durable but susceptible to pipe corrosion over time, reducing safety and lifespan.

Always evaluate the environment and gas type to prevent pipe corrosion and ensure material compatibility, which are key to maintaining safe and efficient gas piping systems. Additionally, understanding the material compatibility with natural gas helps prevent leaks and potential hazards over the system’s lifespan.

Common Mistakes and How to Avoid Them

One common mistake in gas line installation is selecting the wrong material for the environment or gas type, leading to safety hazards and costly repairs. Incorrect installation often results from DIY mistakes, such as improper fitting or neglecting code requirements. To help you avoid these pitfalls, consider the following:

| Mistake | Consequence | How to Prevent |

|---|---|---|

| Using incompatible materials | Leaks, corrosion | Verify material compatibility |

| Overlooking pressure ratings | Line failure, explosions | Check pressure specifications |

| Improper sealing or fittings | Gas leaks, safety risk | Use proper fittings and sealants |

| Ignoring local codes | Fines, unsafe setup | Follow all local regulations |

Staying informed and following proper procedures reduces DIY mistakes and ensures safe, compliant gas line installation.

Installing Gas Lines Safely and According to Regulations

To install gas lines safely and in compliance with regulations, you must follow established codes and best practices at every step. Proper installation minimizes risks, ensures gas leak prevention, and allows quick response in emergencies. Here are key steps to contemplate:

- Verify local codes and obtain necessary permits before starting.

- Use approved materials designed for gas line installation.

- Install an accessible emergency shutoff valve at the main supply point.

- Ensure all connections are tight and tested for leaks before use.

Following these practices helps prevent gas leaks and ensures quick shutoff during emergencies. Proper installation not only complies with safety standards but also protects you and your property. Never skip inspections or ignore manufacturer recommendations—safety depends on meticulous compliance.

Inspection and Certification Requirements

After completing the installation of your gas lines, it’s important to move on to inspection and certification processes to guarantee everything meets safety standards. During inspection, professionals check for proper gas leak detection and ensure the emergency shutoff systems are functioning correctly. Certification confirms the installation complies with local codes and safety requirements. The inspector will verify all connections, test for leaks, and review safety devices. If issues arise, you’ll need to address them before receiving certification. Proper inspection and certification help prevent hazards, ensuring your system operates safely.

| Inspection Step | Purpose |

|---|---|

| Gas leak detection | Confirm no leaks are present after installation |

| Emergency shutoff | Verify shutoff devices work correctly |

| Final approval | Certify system meets safety and code standards |

Resources for Staying Updated on Gas Code Changes

Staying informed about updates to gas code regulations is essential for ensuring your installations remain compliant and safe. Keeping up with changes helps you improve gas leak prevention measures and ensures emergency shutdown procedures are current. To stay updated, consider these resources:

- Industry organizations like the NFPA (National Fire Protection Association) regularly publish code updates.

- Local building departments often provide updates on regional code amendments.

- Manufacturer bulletins and technical support can offer insights into product-specific compliance.

- Professional training courses and seminars keep you informed on the latest safety standards and emergency shutdown protocols.

Using these resources ensures your work aligns with current regulations, reducing risk and maintaining safe, reliable gas systems.

Frequently Asked Questions

How Often Are Gas Line Codes Updated or Revised?

Gas line codes are typically updated every few years, depending on the regulatory agencies overseeing them. You should stay aware of code evolution, as agencies like the NFPA or local authorities revise standards to improve safety and efficiency. These updates guarantee that you follow the latest safety practices and comply with current regulations. Regularly check for updates, so your gas line installations remain compliant and safe according to the newest codes.

What Are the Penalties for Non-Compliance?

Ignoring gas line codes exposes you to serious liability risks and potential insurance issues. Penalties can include hefty fines, project shutdowns, and even criminal charges if accidents occur. Your insurance might deny claims due to non-compliance, leaving you financially vulnerable. Think of it as a safety net — following codes keeps you protected, ensuring your project runs smoothly and your liability risks stay minimized. Don’t gamble with safety or financial security.

Can DIY Homeowners Legally Install Gas Lines?

You generally can’t legally perform DIY installation of gas lines due to homeowner restrictions and safety regulations. Many areas require licensed professionals to guarantee proper sizing, code compliance, and safety standards. Attempting a DIY installation can lead to penalties, safety hazards, and voided insurance. Always check local codes and hire a licensed expert to handle gas line work, ensuring your home’s safety and compliance with regulations.

How Do Weather Conditions Affect Gas Line Installation?

Weather conditions profoundly impact gas line installation, creating potential challenges you need to address. Cold temperatures can cause materials to contract or become brittle, making installation more difficult and risking damage. Rain and snow increase the risk of corrosion and complicate work, while high winds can pose safety hazards. You should plan for weather impact, delay work during extreme conditions, and guarantee proper insulation and protection to maintain safety and compliance.

Are There Specific Safety Standards for Underground Gas Lines?

Are you aware of the safety standards for underground gas lines? You should follow strict codes that focus on gas leak prevention and guarantee proper installation. These standards include regular inspections, corrosion protection, and secure trenching. Also, you need emergency response protocols in place to handle potential leaks swiftly. Do you know how to respond if a gas leak occurs? Adhering to these safety standards keeps you and your community safe.

Conclusion

By understanding and following proper gas line sizing codes, you guarantee safety and reliability in your projects. When you prioritize compliance, you not only prevent costly mistakes but also create a safer environment for everyone. Sometimes, a small detail can make all the difference—like choosing the right pipe or double-checking regulations. Ultimately, your careful attention turns a simple task into a lasting legacy of safety and trust.