To avoid guessing, you need to understand NEC standards for standby systems clearly. Focus on proper sizing, installation, wiring, grounding, and fuel safety to guarantee compliance and reliability. Knowing key terminology and adhering to codes prevents common violations. Regular maintenance and inspections keep systems safe and efficient. By following these expert highlights, you’ll build a solid foundation—keep going to uncover more essential details for your project.

Key Takeaways

- Ensure generator capacity matches NEC standards and accurately reflects critical load calculations.

- Follow proper wiring, grounding, and bonding practices for safety and compliance.

- Select and install transfer switches appropriately, considering manual or automatic options.

- Use proper fuel handling, storage, ventilation, and maintenance procedures for safety and reliability.

- Regularly inspect, test, and document standby system components to prevent violations and ensure ongoing compliance.

Understanding the Scope of Standby Systems According to NEC

Understanding the scope of standby systems according to NEC is essential for ensuring safety and compliance. The NEC classifies standby systems based on their fuel types, such as diesel, natural gas, or propane, which impact installation and safety requirements. It’s important to recognize that different fuel types demand specific handling procedures and equipment considerations. Additionally, noise regulations play a role in standby system design, especially in sensitive environments like residential or healthcare facilities. The NEC specifies acceptable noise levels to prevent disturbances and ensure safety for occupants. By understanding these key aspects—fuel types and noise regulations—you ensure your standby power systems meet NEC standards, operate efficiently, and stay compliant with safety codes. Being aware of fuel handling procedures helps prevent accidents and ensures proper maintenance of standby systems.

Key Definitions and Terminology for Standby Power Systems

- Standby power: Power supplied during outages, guaranteeing critical systems stay operational.

- Automatic transfer switch (ATS): Device that switches power sources seamlessly during outages.

- Run time: Duration a generator can operate on its fuel or battery capacity.

- Load: The amount of electrical power consumed by connected equipment.

- Understanding power management is essential for maintaining efficient and reliable standby systems.

Proper Sizing and Capacity Requirements for Standby Generators

To guarantee your standby generator meets your needs, you need to accurately calculate your load and understand code compliance standards. Proper sizing also considers future expansion plans to avoid costly upgrades later. Additionally, reviewing ventilation considerations ensures safe and efficient operation of your system. By focusing on these points, you’ll select a generator that provides reliable backup power now and in the future.

Load Calculation Techniques

Accurately sizing standby generators requires careful load calculation to guarantee they can handle the essential power demands during an outage. Start by analyzing your load profile with attention to load balancing, ensuring no single circuit overloads the system. Consider the power factor, as it affects the actual capacity needed; a lagging power factor can reduce efficiency. To calculate the required capacity, identify all critical loads and sum their demands, adjusting for simultaneous operation. Remember to:

- Assess each load individually

- Account for concurrent usage

- Adjust for power factor correction

- Include future expansion needs

- Use flow rate considerations to ensure your generator can support peak demands during outages

This approach guarantees your generator is neither undersized nor oversized, optimizing performance while maintaining reliability during outages. Proper load calculation is crucial for effective standby system design and operation.

Code Compliance Standards

Ensuring your standby generator meets code compliance standards is essential for safe and reliable operation. Proper sizing is key; the generator must handle your essential loads without overloading. When considering generator placement, follow clearance requirements to prevent fire hazards and facilitate maintenance. Fuel system requirements are equally critical; guarantee your fuel source is adequately rated and protected against leaks and spills, meeting local codes. Proper ventilation and outdoor installation help prevent dangerous buildup of exhaust gases. Avoid undersizing, which can lead to frequent outages, or oversizing, which wastes resources. Always verify that your generator’s capacity aligns with NEC standards and manufacturer specifications. Additionally, regular system inspections can identify potential issues early, ensuring ongoing compliance and safety. Adhering to these guidelines guarantees your system functions safely, efficiently, and in compliance with all relevant codes.

Future Expansion Planning

Planning for future expansion involves carefully evaluating your current generator capacity and anticipating your evolving power needs. To guarantee seamless growth, you should consider proper sizing to handle increased loads, factoring in future equipment and facility upgrades. Effective battery management becomes vital to maintain backup reliability as demands grow. Additionally, assess your fuel storage capacity to support larger generators and extended run times without interruptions. Here are key considerations:

- Future load calculations to prevent under or over-sizing

- Scalable generator models for easy capacity expansion

- Adequate fuel storage solutions for increased consumption

- Battery management systems to optimize backup performance

- Proper system sizing ensures your backup power remains reliable as your needs expand.

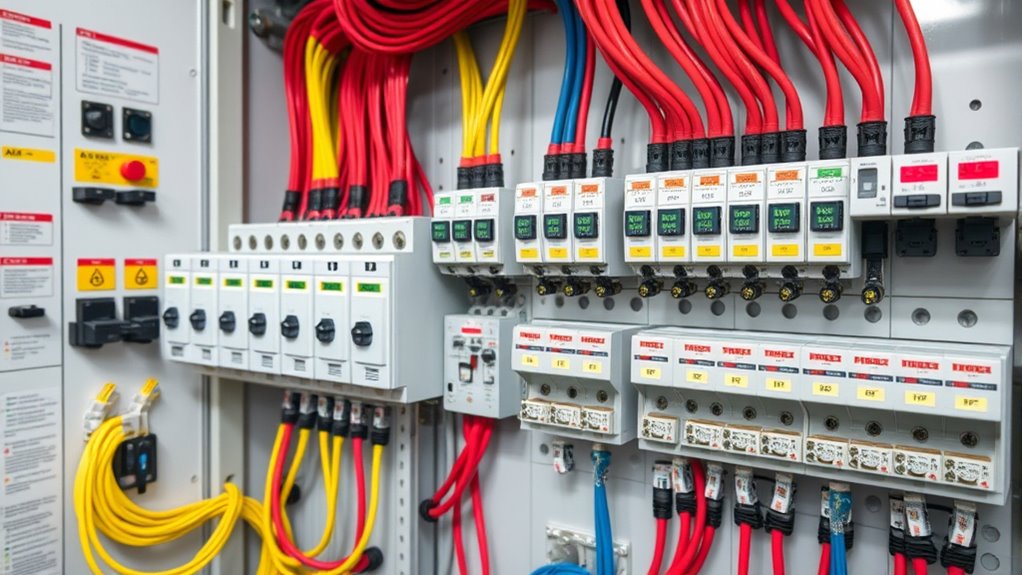

Installation Guidelines for Safe and Compliant Systems

To install standby systems safely and in compliance with NEC requirements, you must follow specific guidelines that prioritize proper wiring, grounding, and equipment placement. Selecting the right fuel is essential for system reliability and safety; verify your fuel choice matches your system’s capacity and local codes. Proper fuel storage and ventilation prevent hazards and ensure continuous operation. Additionally, pay attention to system aesthetics—choose discreet equipment locations that blend with your environment without compromising accessibility. Secure wiring connections, use approved conduit, and maintain clear labeling to avoid confusion. Grounding must meet NEC standards to prevent electrical shock risks. Proper installation practices are crucial for ensuring system safety and compliance. By adhering to these guidelines, you ensure your standby system functions safely, remains compliant, and integrates seamlessly into your property’s overall design.

Electrical Wiring and Connection Standards for Standby Power

When setting up standby power systems, you need to follow proper grounding techniques to guarantee safety and system reliability. Correct wiring practices are essential to prevent electrical faults and maintain compliance with the NEC. Let’s review the key standards for wiring and connections to keep your system safe and effective. Using appropriate self-watering plant pot materials can also help maintain consistent moisture levels, reducing the risk of overwatering and root rot in your system.

Proper Grounding Techniques

Proper grounding is essential for guaranteeing the safety and reliability of standby power systems. Effective grounding techniques help prevent electrical shocks, protect equipment, and ensure system stability. To achieve this, follow proven grounding practices such as:

- Using grounding electrodes compliant with NEC standards

- Connecting all grounding conductors securely to the grounding bus

- Maintaining low-resistance grounding paths for effective fault current dissipation

- Regularly inspecting and testing grounding connections for integrity

- Incorporating remote work strategies can facilitate ongoing maintenance and inspections without physical presence.

Correct Wiring Practices

Ensuring correct wiring practices is vital for the safety and efficiency of standby power systems. Proper wiring minimizes risks and guarantees reliable operation. You should always adhere to electrical wiring standards, using appropriately rated circuit protection devices to prevent overloads and short circuits. Proper grounding is essential, but so is correct connection of conductors for safety and performance. Incorporate surge suppression devices to protect sensitive components from voltage spikes. Avoid daisy chaining connections or overloading circuits, which can compromise system integrity. Use quality connectors and secure wiring to prevent accidental disconnections. Regular inspections help identify potential issues early. Additionally, understanding Vetted wiring techniques ensures compliance with industry standards and reduces the risk of failures. By following these wiring practices, you guarantee your standby system remains reliable, safe, and compliant with NEC standards.

Transfer Switches: Types and Installation Considerations

Transfer switches are critical components in standby systems, enabling seamless power transfer between the utility grid and backup generators. Choosing the right transfer switch types guarantees reliability and compliance with NEC standards. When considering installation tips, focus on proper placement, accessibility, and ensuring it matches your system’s capacity.

Key factors include:

- Selecting manual or automatic transfer switches based on your needs

- Ensuring proper wiring connections for safety and efficiency

- Verifying the switch’s compatibility with your generator size

- Following manufacturer instructions and NEC requirements during installation

Understanding these transfer switch types and adhering to installation tips helps prevent electrical issues, enhances system responsiveness, and ensures your standby system functions flawlessly when needed most.

Grounding and Bonding Practices for Standby Systems

Grounding and bonding are indispensable for the safe and reliable operation of standby systems. Proper grounding ensures that any fault current is safely directed to the earth, reducing shock hazards and equipment damage. Bonding creates a continuous electrical path, helping to minimize voltage differences that could cause equipment failure. To protect your system, include surge protection devices at critical points, preventing voltage spikes that can harm sensitive components. Additionally, cable labeling is crucial for clear identification of grounding conductors, surge protection devices, and bonding connections, simplifying troubleshooting and maintenance. Follow NEC standards carefully to ensure all grounding and bonding practices are compliant, safe, and effective. Proper implementation reduces risks and enhances the overall reliability of your standby system during power interruptions.

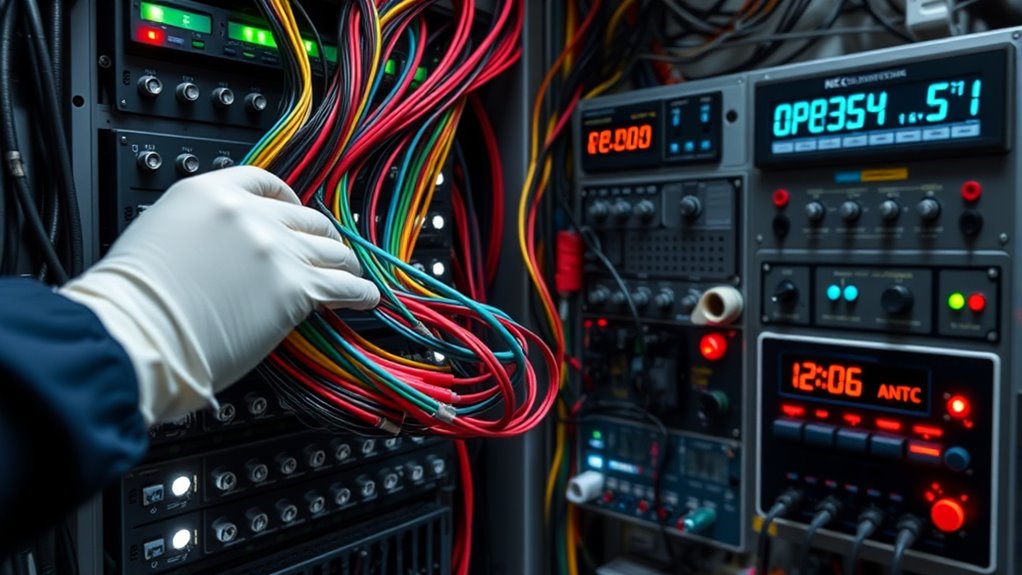

Maintenance and Testing Procedures to Ensure Reliability

Regular maintenance and testing are essential to keep standby systems reliable and ready when needed. You must follow established testing protocols to verify system performance and identify issues early. Proper battery maintenance is vital; regularly check electrolyte levels, terminal connections, and overall battery health. Implement routine inspections to detect corrosion, leaks, or damage. Test transfer switches and emergency circuits periodically to ensure seamless operation during outages. Document all maintenance activities and test results for compliance and troubleshooting. Key practices include:

- Conducting scheduled battery capacity tests

- Verifying backup power source functionality

- Inspecting wiring and connections for integrity

- Updating testing protocols based on manufacturer recommendations

Sticking to these procedures helps prevent failures and guarantees your standby system performs flawlessly when it counts.

Common Code Violations and How to Avoid Them

One common mistake is improper system sizing, which can lead to safety issues and code violations. Ensuring you select the correct size for your standby system helps maintain compliance and reliability. Additionally, following proper wiring practices prevents costly errors and keeps your installation up to code.

Proper System Sizing

Proper system sizing is crucial to guarantee standby systems operate reliably and comply with code requirements. Incorrect generator sizing can lead to insufficient power or unnecessary expenses, while poor load management causes overloads and system failures. To avoid these issues, focus on:

- Accurately calculating the load demand, including future expansions

- Ensuring generator capacity matches the total connected loads

- Prioritizing critical loads to optimize generator use

- Regularly reviewing and updating load calculations as systems evolve

Proper generator sizing ensures your standby system can handle peak loads without overtaxing components. Load management strategies help prevent overloads, extend equipment life, and maintain compliance with NEC standards. By paying close attention to these factors, you improve reliability and avoid common code violations related to improper system sizing.

Correct Wiring Practices

Incorrect wiring practices are a common cause of code violations and system failures in standby power setups. To prevent issues, guarantee proper circuit protection by using the correct overcurrent devices and grounding methods. Avoid daisy-chaining multiple circuits, which can compromise system reliability. Proper battery management is vital; always use dedicated wiring for batteries, maintain appropriate fuse sizing, and follow manufacturer instructions. Improper wiring can lead to short circuits, overloads, or damage to critical components. Regular inspections help identify loose connections or damaged wiring that could cause failures. Remember, neat, organized wiring not only simplifies maintenance but also reduces risk. Adhering to NEC standards for wiring practices guarantees your system’s safety, reliability, and compliance.

Staying current with changes in NEC standards is essential for ensuring your standby systems remain compliant and safe. As standards evolve, updates often address critical areas like battery backup safety, generator noise reduction, and system reliability. To keep pace, regularly review NEC amendments, attend training sessions, and consult official updates. This proactive approach helps you anticipate new requirements and avoid code violations. Key areas to watch include:

- Updated guidelines for battery backup installation and maintenance

- Restrictions on generator noise levels to prevent disturbances

- Requirements for proper grounding and wiring practices

- New standards for testing and maintenance procedures

Remaining informed ensures your systems operate efficiently, meet legal requirements, and protect occupants. Adaptation to NEC updates safeguards your investments and enhances overall safety.

Frequently Asked Questions

How Do Standby Systems Impact Overall Building Safety?

Standby systems markedly enhance your building’s fire safety and emergency preparedness. When power outages occur, these systems activate automatically, ensuring critical safety equipment like alarms, sprinklers, and emergency lighting stay operational. This minimizes risks during emergencies, protecting occupants and property. You can trust standby systems to provide reliable backup power, giving you peace of mind that your building remains safe and compliant with safety standards during unforeseen events.

What Are the Costs Associated With Proper Standby System Installation?

You’ll find that proper standby system installation involves costs like a thorough cost analysis, equipment, and labor. While initial expenses can be substantial, investing in quality guarantees safety and compliance. Be aware of installation challenges, such as space constraints or complex wiring, which might add to costs. However, these investments protect your building, prevent downtime, and save money long-term by avoiding costly failures or code violations.

How Can Owners Ensure Ongoing Compliance With NEC Updates?

Imagine you’re managing a hospital’s standby system, and regular inspections reveal code updates. To guarantee ongoing compliance with NEC updates, you must establish strict inspection protocols and adhere to scheduled maintenance. Regularly review NEC amendments, train your team on new standards, and document all procedures. This proactive approach keeps your system compliant, minimizes failures, and guarantees reliable emergency power, ultimately safeguarding lives and property efficiently.

What Training Is Recommended for Installing Standby Power Systems?

You should pursue specialized training in generator maintenance and battery backup systems to guarantee proper installation of standby power systems. Look for courses offered by manufacturers or certified industry organizations, focusing on NEC compliance and safety standards. Hands-on experience is vital, so seek workshops or apprenticeships. Staying updated on NEC code changes helps you install systems that are reliable and compliant, reducing potential failures and ensuring continuous power during outages.

How Do Environmental Factors Affect Standby Generator Performance?

Environmental factors profoundly impact your standby generator’s performance. Poor environmental resilience, like exposure to extreme temperatures or humidity, can cause overheating or corrosion, reducing efficiency. Temperature regulation is vital; high temperatures strain the system, while cold conditions can hinder starting. Make certain proper ventilation and protective enclosures to maintain ideal operation, and regularly inspect for environmental damage. This proactive approach helps your generator stay reliable during power outages.

Conclusion

By understanding NEC standards, you build a sturdy shield around your standby system, ensuring it’s always ready when needed. Think of your system as a reliable lighthouse, guiding your facility safely through stormy outages. Stay vigilant with proper sizing, wiring, and maintenance, so your backup power stands firm against any darkness. When you follow these rules, you illuminate a clear path to safety and compliance, keeping your operations steady and secure, no matter what comes your way.