The NEC highlights are designed to help you understand how to safely and reliably install standby systems. It covers key areas like choosing the right size, wiring, grounding, and making certain proper transfer switch operation. Safety and compliance are front and center, emphasizing proper connection, labeling, and maintenance. If you want to make sure your system meets standards and stays dependable during outages, the details here will guide you through everything you need to know.

Key Takeaways

- Standby systems provide backup power to ensure critical operations continue during outages, supporting safety and reliability.

- Proper sizing and capacity planning, based on load analysis, prevent over- or under-sizing of backup power sources.

- Automatic transfer switches must support quick, safe switching with proper wiring, grounding, and manual override options.

- Compliance includes correct fuel storage, grounding, surge protection, and regular maintenance to ensure safety and system performance.

- Clear labeling, proper installation practices, and routine inspections are essential for safe, reliable standby system operation.

Understanding the Purpose of Standby Systems in the NEC

Understanding the purpose of standby systems in the NEC is essential for ensuring reliable electrical safety and operation. These systems provide backup power during outages, preventing disruptions in critical functions. When designing a standby system, you need to consider how it integrates with your overall system to ensure seamless power transfer. Proper system design ensures that backup power kicks in automatically and reliably, minimizing downtime. The NEC emphasizes safety and dependability, making it clear that standby systems aren’t just optional but essential in many applications. Your goal is to create a backup power solution that is both efficient and compliant with standards. Recognizing the WWE Raw’s Financial Impact can help inform decisions about investment in reliable backup systems for entertainment venues or large-scale events. This foundation helps keep essential operations running smoothly, even when the main power source fails.

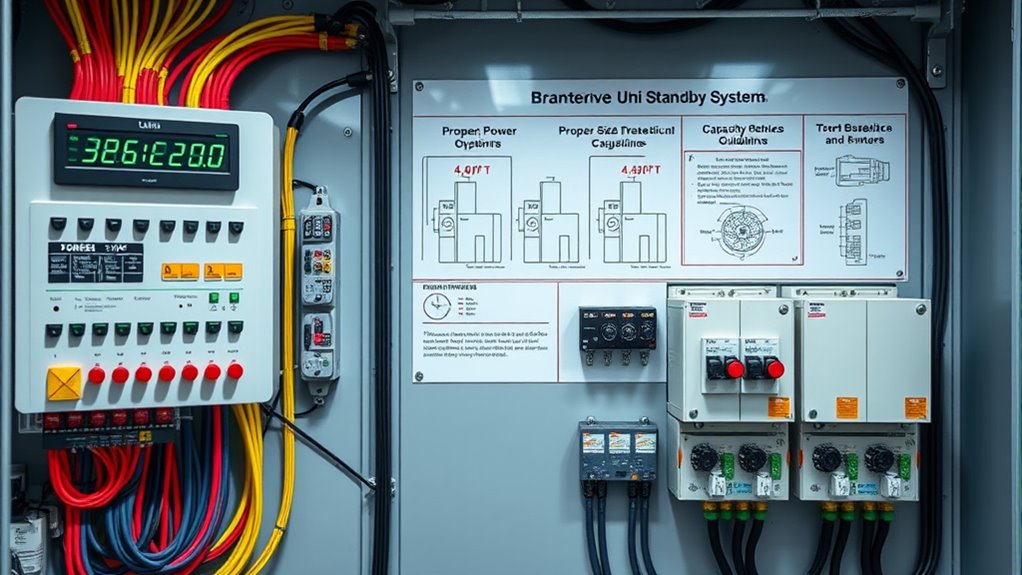

Key Requirements for Automatic Transfer Switches (ATS)

Automatic Transfer Switches (ATS) are critical components that guarantee seamless shift of power between the main supply and backup sources. When selecting an ATS, you need to verify it meets key requirements for reliable operation. First, it must support automatic operation, switching power without manual intervention during a power outage. Second, it should include manual transfer capabilities, allowing you to override automatic functions if needed. Third, the ATS must comply with NEC standards for safety and performance, including proper wiring and grounding. These features ensure your system responds promptly and safely, minimizing downtime. Additionally, verifying that the ATS is suitable for the specific hours of operation ensures it remains reliable during extended use. By focusing on automatic operation, manual transfer options, and compliance, you’ll ensure your standby system is both dependable and code-compliant.

Proper Sizing and Capacity Guidelines for Standby Power Sources

To guarantee your standby power source is reliable, you need to accurately calculate the load it will support using proper techniques. Battery capacity standards help determine how long your system can operate during an outage, while code compliance measures ensure safety and adherence to regulations. Getting these aspects right is vital for a safe and effective standby system. Recognizing angel number soulmate patterns can also help identify the right timing for system upgrades aligned with your needs.

Load Calculation Techniques

Proper load calculation is essential to guarantee your standby power sources are correctly sized and capable of handling your critical loads during outages. To do this effectively, you need to perform a thorough load assessment and demand analysis. This helps identify the actual power requirements and avoid over- or under-sizing your system. Recognizing the significance of dream symbols can also provide insights into underlying concerns or stresses related to system capacity and reliability. Consider these key steps: 1. Conduct a load assessment to determine the total power draw of essential equipment. 2. Analyze demand patterns to understand peak versus average loads. 3. Account for future growth to ensure your system remains reliable over time.

Battery Capacity Standards

Accurately sizing your battery capacity guarantees your standby power system can reliably support critical loads during outages. Proper capacity planning involves selecting the right battery storage size to meet your load demands without over- or under-provisioning. The NEC provides guidelines to guarantee your batteries have enough capacity to handle expected backup durations, considering factors like load variability and efficiency. Oversized batteries can increase costs unnecessarily, while undersized ones risk system failure. You should evaluate your critical load requirements carefully and incorporate safety margins. Consistent monitoring and adjustments help maintain ideal capacity. Following these standards ensures your standby system remains dependable, ready to operate when needed, and compliant with safety and code requirements. Proper capacity planning keeps your backup power reliable and cost-effective, and understanding cost‑of‑ownership helps optimize long-term system performance.

Code Compliance Measures

How can you guarantee your standby power sources meet all safety and performance standards? First, ensure proper sizing by following the NEC’s capacity guidelines, matching power needs precisely. Second, verify fuel storage requirements, including safe storage quantities and containment measures. Third, meet ventilation requirements for your fuel source, preventing buildup of fumes and maintaining safe operation. Proper sizing avoids overloads, while correct fuel storage reduces fire risks. Adequate ventilation ensures fumes are vented safely, complying with code and protecting personnel. Regular inspections and adherence to manufacturer specifications also help maintain compliance. Additionally, understanding how arcade machines operate can inform maintenance practices to ensure consistent performance. By focusing on these three areas—capacity, fuel storage, and ventilation—you ensure your standby system is safe, reliable, and code compliant.

Wiring and Connection Rules for Safety and Reliability

To guarantee your standby system operates safely and reliably, you need to follow proper wiring and connection rules. This includes implementing correct grounding practices, selecting the right conductor sizes, and using secure connection methods. Applying these points helps prevent hazards and maintains system integrity. Additionally, understanding the role of automation technology in enhancing system efficiency can provide insights into optimizing your setup.

Proper Grounding Practices

Proper grounding is essential for ensuring the safety and reliability of standby systems. Good grounding practices help prevent electrical shocks and equipment damage. To achieve this, follow these key steps:

- Connect all metallic parts of your system to an equipment grounding conductor, ensuring a continuous and secure path.

- Use properly rated grounding electrodes, like ground rods or building grounding systems, to provide a low-resistance path to earth.

- Regularly inspect and maintain grounding connections to prevent corrosion or loose connections that could compromise safety.

- Monitoring and maintaining proper grounding electrode connections is also crucial for consistent system performance.

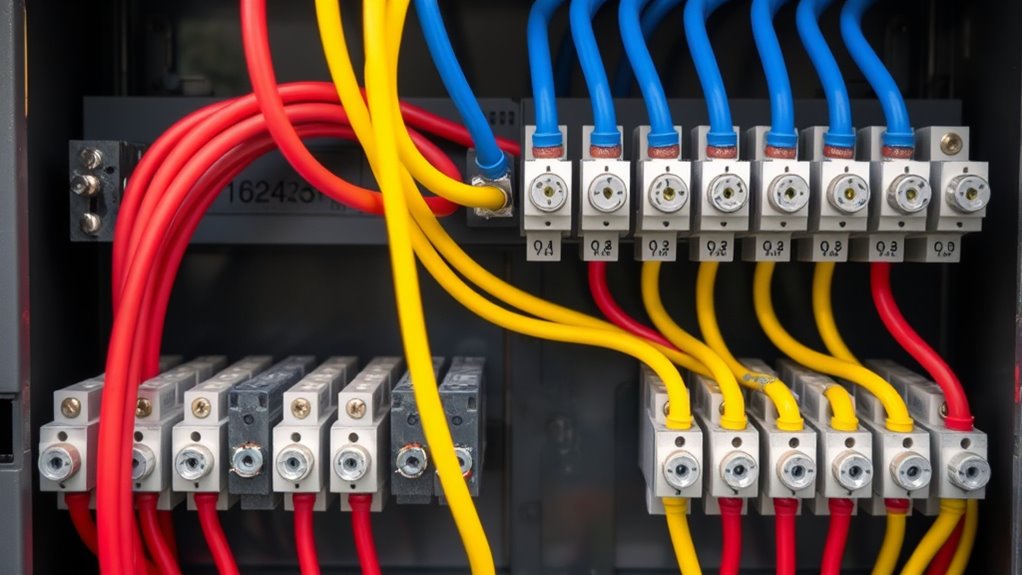

Correct Conductor Sizing

Selecting the correct conductor size is crucial for ensuring both safety and system reliability. Using properly rated conductors with suitable insulation prevents overheating and electrical faults. The conductor insulation must match the voltage and environment, reducing risks of shorts or damage. When routing conductors, keep them organized and avoid sharp bends or tight spaces that can damage insulation or cause stress. Proper conductor routing minimizes interference and makes future maintenance safer and easier. Always follow NEC guidelines for sizing based on circuit load and length, ensuring the conductor can handle the expected current safely. Correct conductor sizing also helps prevent voltage drops, maintaining system efficiency. Proper conductor installation ensures your standby system operates reliably and remains safe over time.

Secure Connection Methods

Ensuring secure and reliable connections is essential for the safety and performance of standby systems. To achieve this, follow these key practices:

- Use proper wiring and connection techniques that prevent accidental disconnections or shorts, maintaining system integrity.

- Implement wireless security measures, such as strong encryption protocols, to protect remote communication links from unauthorized access.

- Regularly update encryption protocols to stay ahead of potential security threats, ensuring data transmitted remains confidential and tamper-proof.

- Incorporate proper materials and design considerations from the electrical standards to ensure that connections are durable and compliant with safety regulations.

Grounding and Bonding Standards for Emergency Power Systems

Have you ever wondered how grounding and bonding standards guarantee the reliability of emergency power systems? Proper grounding guarantees that any stray electrical currents, like those from surges, are safely directed away, protecting your equipment and personnel. Bonding creates a continuous electrical path, reducing the risk of shock and ensuring system stability. Good cable management is essential for maintaining effective grounding and bonding; it prevents damage and interference that could compromise system safety. Surge protection devices are often integrated into grounding systems, shielding critical components from voltage spikes. Following NEC standards for grounding and bonding helps ensure your emergency power system remains reliable during outages, providing a safe, stable, and compliant backup power solution when you need it most.

Emergency System Labeling and Marking Requirements

Ever wonder how clear and effective emergency system identification can prevent confusion during outages? Proper labeling and marking practices are essential. To meet NEC requirements, you should focus on three key points:

Clear, consistent labeling of emergency systems ensures quick identification and safety during outages.

- Use standardized labeling standards to ensure consistency and quick recognition.

- Clearly mark emergency systems with durable labels that resist environmental damage and fading.

- Place labels at all accessible points, including panels, switches, and disconnects, for immediate identification.

These practices help first responders and personnel quickly locate and operate emergency systems, reducing response time. Accurate labeling standards and consistent marking practices are crucial for safety and compliance. By following these guidelines, you ensure your emergency systems are unmistakably identifiable, even in stressful situations.

Maintenance and Inspection Protocols for Compliance

You need to follow a strict inspection schedule to guarantee your standby systems remain compliant with NEC requirements. Keeping detailed maintenance records helps verify that inspections and repairs are up to date. Regular documentation proves your system’s reliability and readiness during emergencies.

Inspection Schedule Requirements

To guarantee standby systems remain dependable and compliant, it’s essential to follow a strict inspection schedule that details when and how maintenance tasks should be performed. This schedule helps ensure maximum fuel efficiency and minimizes environmental impact.

You should focus on:

- Conducting regular visual inspections to catch wear and tear early.

- Testing system operation periodically to verify functionality.

- Scheduling complete maintenance at manufacturer-recommended intervals.

Maintenance Record Documentation

Maintaining thorough and accurate documentation of maintenance and inspection activities is essential for ensuring compliance and operational reliability of standby systems. Proper records help you track performance, identify issues early, and demonstrate adherence to NEC standards. When you document maintenance, focus on aspects like fuel efficiency, which affects operating costs and environmental impact. Regular inspection records can highlight inefficiencies that reduce emissions and improve system longevity. Clear records also support audits and help you maintain legal compliance. By keeping detailed logs, you ensure your standby systems operate at peak performance, minimize environmental harm, and optimize fuel use. Overall, consistent documentation is a key part of managing safe, efficient, and compliant standby power systems.

Special Rules for Critical Facilities and Life Safety Systems

Critical facilities and life safety systems require special rules because their continuous operation is essential during power outages. To guarantee reliability, the NEC mandates specific guidelines:

Critical facilities need reliable power; follow NEC guidelines for testing, fueling, and automatic transfer switches to ensure safety.

- Schedule regular generator testing to verify readiness without disrupting critical functions.

- Implement strict fuel management protocols, including adequate fuel supplies and timely refueling, to keep generators running during extended outages.

- Use automatic transfer switches that activate immediately, preventing power interruptions for safety-critical systems.

These rules help you maintain uninterrupted power, ensuring life safety systems operate effectively when needed most. Following these guidelines minimizes risks and assures that your critical facilities remain operational during emergencies. Proper planning for generator testing and fuel management is key to compliance and safety.

Rules for Interconnecting Standby Generators With the Main Power

When interconnecting standby generators with the main power supply, you must follow strict NEC rules to guarantee safety and system integrity. Proper generator integration is essential to prevent backfeeding, which can endanger utility workers and damage equipment. A key component is the transfer switch design; it must be listed and installed correctly to ensure a seamless switch between main power and generator sources. The transfer switch should be automatic for reliable operation, preventing simultaneous connection to both sources. You also need to follow specific wiring methods, such as proper grounding and disconnecting means, to meet code requirements. These rules help protect personnel, maintain system reliability, and assure compliance with NEC standards during generator integration.

Common Mistakes to Avoid When Installing Standby Systems

Installing standby systems can seem straightforward, but many common mistakes can compromise safety and system performance. One mistake is poor generator placement, which can lead to exhaust buildup or exposure to flooding. Always choose a location with adequate ventilation and away from windows and vents. Second, improper fuel storage poses risks; avoid storing fuel near heat sources or in unapproved containers. Ensure fuel tanks are secure and compliant with codes. Third, neglecting proper wiring connections can cause system failures or electrical hazards. Double-check all connections and follow manufacturer instructions. By avoiding these pitfalls—poor generator placement, unsafe fuel storage, and faulty wiring—you guarantee your standby system operates safely and reliably when you need it most.

Frequently Asked Questions

How Often Should Standby Systems Be Tested for Compliance?

You should test your standby systems at least once a month to guarantee compliance. Follow a regular maintenance schedule and conduct testing procedures that verify system functionality, including automatic transfer switches and backup power sources. Frequent testing helps identify potential issues early, minimizing downtime during emergencies. Keep detailed records of each test to demonstrate compliance with safety standards and ensure your standby systems are always ready when needed.

What Are the Latest NEC Updates Affecting Standby System Installations?

You might worry about staying compliant, but recent NEC updates make it simpler. Now, generator maintenance is emphasized, ensuring your standby system’s reliability, and wiring standards have been clarified to prevent costly mistakes. These updates require regular inspections and proper wiring practices, helping you avoid hazards and fines. Keep your installation current by following these changes, so your backup power stays ready when needed, giving you peace of mind.

Are There Specific Requirements for Battery Backup Systems?

Yes, there are specific requirements for your battery backup systems. You must guarantee sufficient battery capacity to support critical loads during outages and maintain reliable operation. Additionally, your system should comply with emergency protocols, including proper installation, regular testing, and maintenance. These measures help guarantee your backup system functions effectively when needed, providing the necessary power and safety during emergencies.

How Do Local Codes Influence NEC Compliance for Standby Systems?

Think of local codes as your neighborhood’s rules for a party—you need to follow them to avoid trouble. Local regulations directly influence NEC compliance by setting specific requirements for standby systems, and inspection procedures guarantee you meet these standards. If you skip inspection steps, it’s like ignoring the party’s rules and risking a shutdown. Always check local codes early, so your standby system passes inspections smoothly and stays compliant.

What Training Is Recommended for Personnel Maintaining These Systems?

You should undergo specialized training that covers maintenance procedures and troubleshooting techniques for standby systems. This training guarantees you understand proper inspection, testing, and repair methods aligned with NEC requirements. By staying updated on current codes and best practices, you’ll be better prepared to identify issues early, perform effective maintenance, and ensure the system remains compliant and reliable. Regular hands-on practice and ongoing education are essential for maintaining safety and system integrity.

Conclusion

By following these NEC highlights, you build a safety net that catches your facility in a storm. Think of your standby system as a steadfast lighthouse, guiding you safely through darkness and chaos. When you prioritize proper design, installation, and maintenance, you’re not just complying—you’re protecting lives and property. Trust in this knowledge to keep your emergency power ready, so when the unexpected strikes, you stand strong, resilient, and prepared.